3D scanner for toothed part

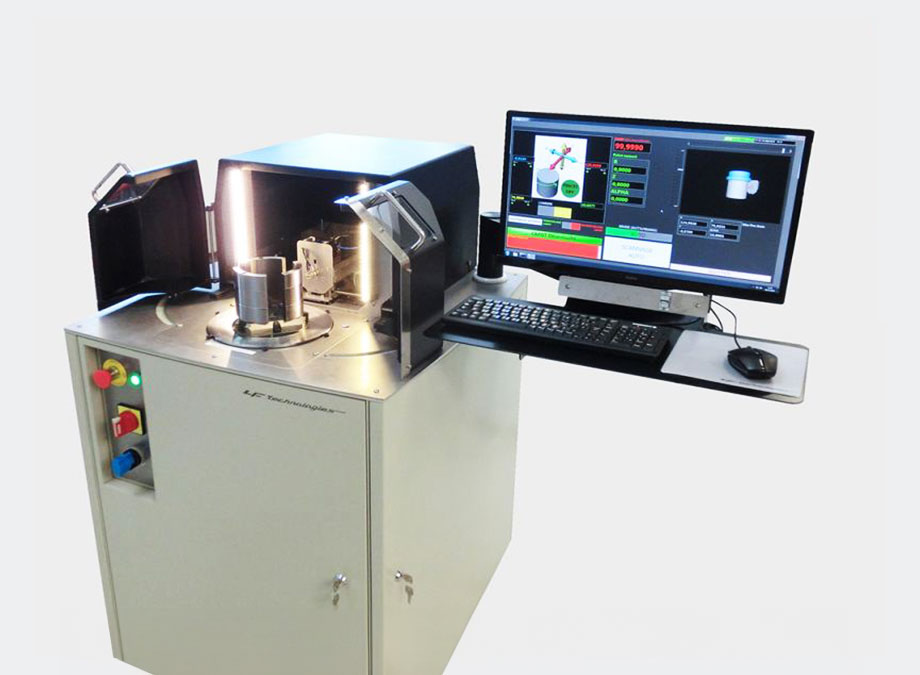

Scanning measurement system developed by LF Technologies. Ensures conformity and similarity of toothed parts. Allows a simpler and faster evaluation.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client specializes in the design, manufacture and distribution of power transmission products and services, including high quality couplings.

Main functions

Objective

Checking the hobbing geometry of a toothed part, in order to be able to detect any drift and correct the machining parameters, directly on the production line.

PROBLEMATIC ISSUES

This type of part is difficult to control by conventional systems (e.g. coordinate measuring machines), especially in a time short enough to be integrated into the production line. In addition, during machining, the test pieces are lubricated, resulting in increased gloss, so measurements by optical systems are difficult.

SOLUTION AND RESULT

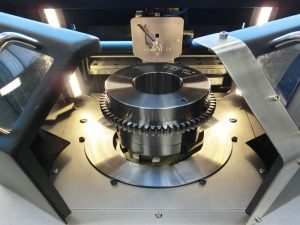

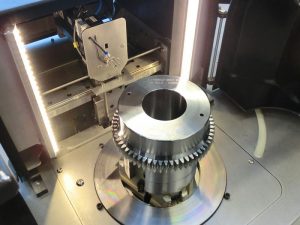

The test bench developed by LF Technologies is designed to measure turning parts with external teeth, and having an internal reference diameter, in order to control:

- Global defects (concentricity of tooth tops and bottoms, tooth crowns, etc.).

- Local defects (tool breakage, circularity, etc.).

Our teams of engineers proposed a high-precision and high-frequency laser scanning measurement system, combined with software for automatic processing of the results.

Measurements are carried out in less than a minute, and automatically analysed in order to produce a detailed results report, associated with machining adjustment parameters.

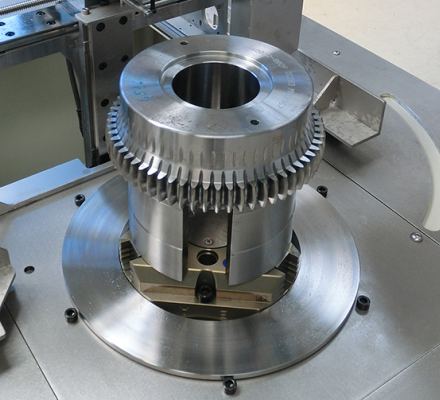

The part to be controlled is fixed on a turntable using a specific adapted tooling. It is scanned according to a program chosen by the operator, by a laser sensor.

The set of scanned points describes a volume in space. It is the analysis of the measurements by the program that enables the extraction, from this cloud of points, of values for concentricity, parallelism, shape defects, etc.

This 3D scanner is a control test bench integrated into a production line. It is designed to control 100% of the production.

Products tested

Toothed mechanical part

It is designed to control 100% of the production. They work by gearing with other toothed parts.

Toothed mechanical part.

It is designed to control 100% of the production. They work by gearing with other toothed parts.

TOOTHED GEAR

TOOTHED GEAR

Test area with loudspeaker

Test area with loudspeaker

Scanning measurement system

Scanning measurement system

3D scanner for toothed part

3D scanner for toothed part

OUR KEY MODULE FOR THIS ASSEMBLY AND CONTROL BENCH Mo-A-Axe-posi-elec

Electric positioning axes allow positioning of a tool or sensor with precise control of position and speed. They can be combined to create multi-axis, rotary or linear systems.

These axes can be controlled in positioner mode, in trajectory mode or servo-controlled according to a measurement.

- Optimized performance

- Precision, dynamic control

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.