Traction Compression Fatigue Bench

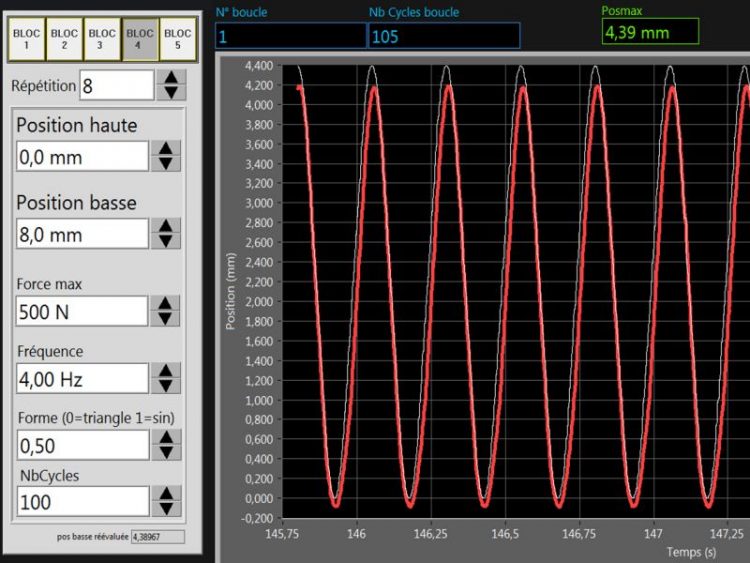

- Simple programming of endurance cycles by linking function blocks

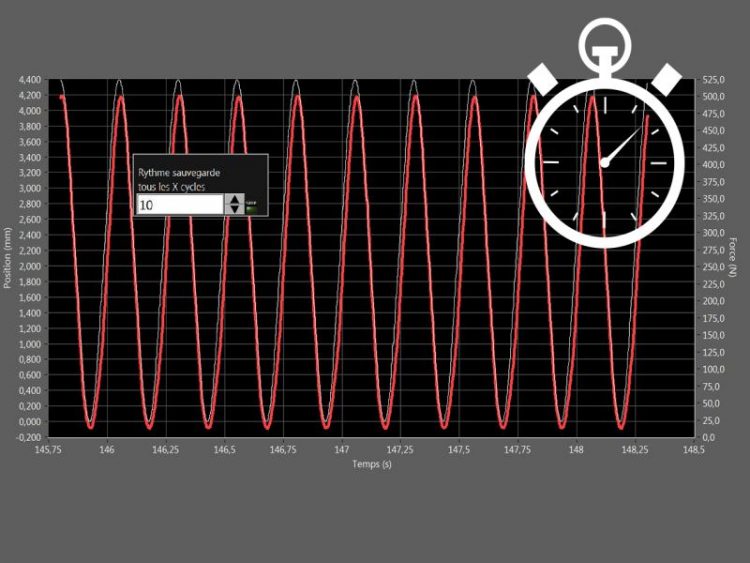

- Automatic saving of measurement files at a configurable rate

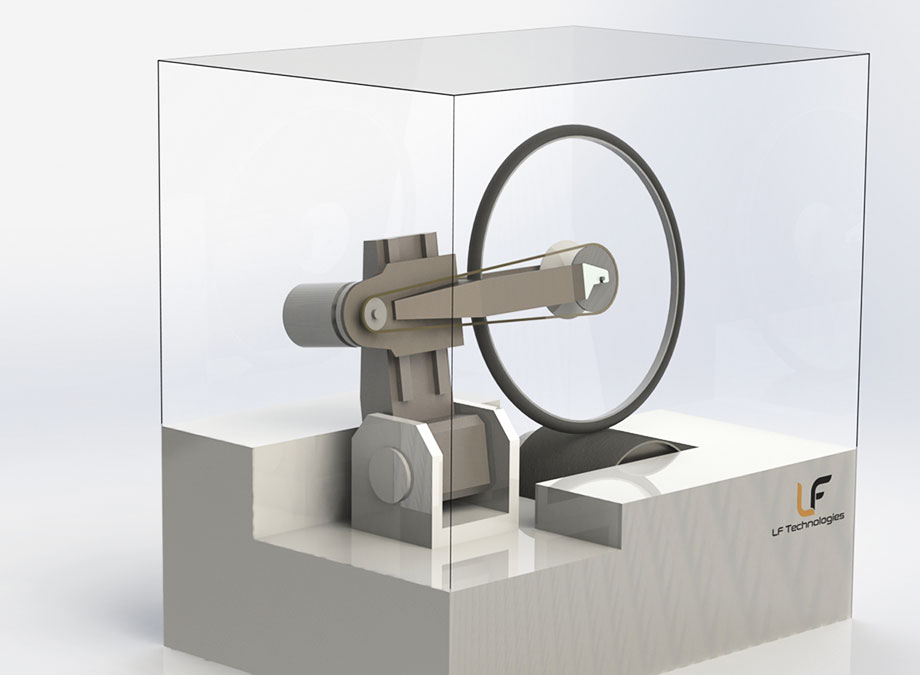

- User protection by glass door, opening the door automatically stops the test

- Electric servo jack with integrated force transducer, designed for maximum service life and endurance

Products tested

Sector of activity

Main functions

Test machines are used to estimate the fatigue life of components and/or finished products. Fatigue tests characterize the ability of a material or product to withstand cyclic loading, in order to reproduce the part’s operating conditions as closely as possible. The tension/compression fatigue test bench enables parts to be tested in tension/compression, with slow or rapid cycling (fatigue testing).

Operating mode

After positioning the part to be tested, the user defines a compression or tension test program, consisting of a sequence of function blocks. Each function performs force- or position-controlled trapezoidal or sinusoidal cycles at an adjustable frequency. The compression/tensile test is automatically stopped if the part under test breaks.

Robust electric cylinder

Electric servo jack with integrated load cell designed for optimum endurance life.

Operator safety

User protection by glass door. Opening the door automatically stops the test.

Tension and compression fatigue test bench

The tension/compression fatigue test bench enables parts to be tested in tension/compression, with slow or rapid cycling (fatigue testing).

Advantages of the fatigue tester

Stirrups

Optimization of equestrian stirrup shapes under various load conditions.

Automotive aerators

Possibility of controlling manoeuvring forces (directions and knob).

Leather goods

Simulation of repeated opening/closing operations.

Simple parameterization

Simple programming of endurance cycles by linking function blocks.

Automatic backup

Automatic recording of measurements at a configurable rate.

Tension and Compression Fatigue Bench

Tensile fatigue test bench on stirrups. The test bench is used to estimate the caliper’s fatigue life. Fatigue tests characterize the stirrup’s ability to withstand cyclic loading, in order to reproduce operating conditions as closely as possible.

TECHNICAL CHARACTERISTICS of the Tension and Compression Fatigue bench

Specifications | MFTC |

Actuator | |

Max. force (tension and compression) | 2 500 N |

Max. fatigue force | 2 000 N |

Max. speed | 200 mm/s |

Max. stroke | 200 mm |

Displacement measurement resolution | 0,01 mm |

Static positioning accuracy | 0,05 mm |

Max. frequency | 10 Hz |

Force sensor | |

Measurement range (tension/compression) | 0-2 500 N |

Measurement accuracy | ±1 N |

Permissible overload | 150 % |

PC link | Ethernet |

Power supply | 230 VAC - 5A |

Dimensions | |

Total height | ≈ 1 900 mm |

Width (excluding desk) | ≈ 500 mm |

Depth | ≈ 550 mm |

Height of test area | ≈ 860 mm |

Weight | ≈ 220 kg |

Customer applications

Would you like to find out more about mechanical test benches? Find out everything you need to know and much more!