Automated seat simulator

This special test rig was used to test seat designs for the aerospace and automotive industries and to measure the comfort of different geometries and kinematics.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is the French Institute of Transport, Planning and Networks Sciences and Technologies (IFSTTAR). IFSTTAR is a major player in European research in various fields such as transport and infrastructure.

Main functions

Objective

To determine objective criteria for measuring the comfort of a seat in order to design new types of seats for the aeronautical or automotive industries, and to establish statistical laws for comfort of use.

PROBLEMATIC ISSUES

The equipment must be able to simulate different seat geometries and quantify the interaction between the seat and the occupant. The conformator is designed for use by adults, covering a wide range of transport users, including overweight people (up to 120 kg);

SOLUTION AND RESULT

LF Technologies has designed a seat shaper to meet the customer’s various requirements. The conformator is made up of several actuators that control the position of sub-assemblies:

- overall inclination of the former

- 2D movement of the floor, 3D movement of the seat, inclination of the backrest, and 2d adjustment of each of the 3 lumbar, back and head supports.

The seat is equipped with a matrix of 52 actuators, which can be controlled individually or in groups. Each cylinder is equipped with a bearing force measurement and a shear force measurement.

An automatic system that detects the risk of interference between different parts of the seat stops movements to avoid collisions.

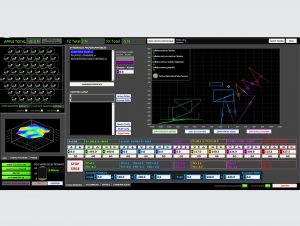

The control PC, using a program developed in LabVIEW, can carry out all the movements of the seat and die, measure positions and forces and modify certain settings.

By default, 3 programmable interfaces are supplied with the software:

Subject control” interface

This interface can be used to link up with the digital tablet supplied, via a Wi-Fi point, so that the operator himself can move the seat or the matrix.

“Lumbar palpation” interface

This interface enables movements to be made on the lumbar support by ‘scanning’ several points on the subject’s back.

Matrix force distribution” interface

This interface allows the die cylinders to be retracted to distribute the support forces as evenly as possible.

The software can also be used to launch “programmable interfaces”. These are developed in LabVIEW and communicate with the main software by receiving force and position measurements and sending position instructions. These programmable interfaces can be developed by researchers and integrated directly into the machine control system.

Users can also create configuration files for the seat and for the matrix, enabling them to save all the measured positions and position the seat or matrix in any saved configuration.

Tested product

Aeroplane, train and car seats

Seats for planes, trains and other means of transport.

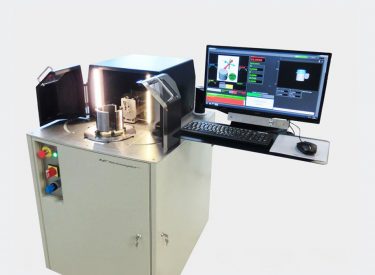

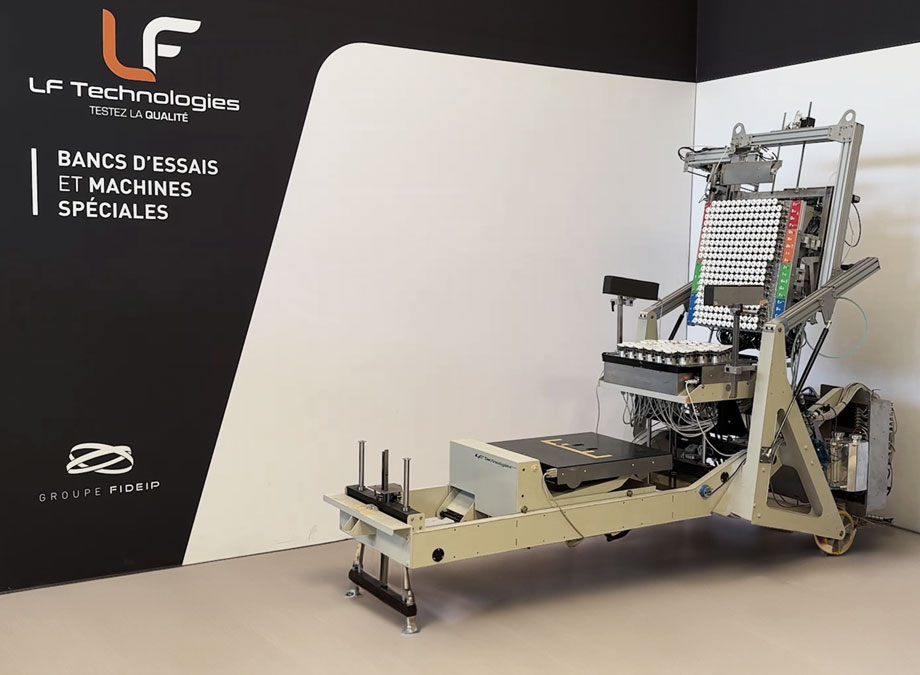

LF Technologies seat shaper

LF Technologies seat shaper

Side view of seat adjuster

Side view of seat adjuster

Seat former cylinder matrix

Seat former cylinder matrix

Zoon on a seat conformer actuator

Zoon on a seat conformer actuator

Train seats

Train seats

Seat former cylinder matrix

Seat former cylinder matrix

Seat conformator main screen

Seat conformator main screen

Seat conformator in operation

Seat conformator in operation

IFSTTAR seat shaper

Simulation of different seat geometries and quantification of the interaction between the seat and the seated person.

The aim is to measure the comfort of a seat in order to design new types of seats for the aeronautical or automotive industries and to establish statistical laws for comfort of use.

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.