Bicycle frame test bench

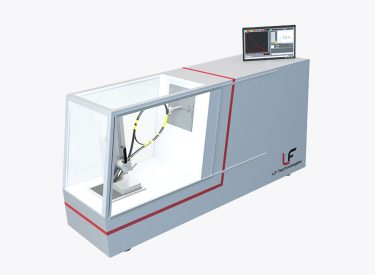

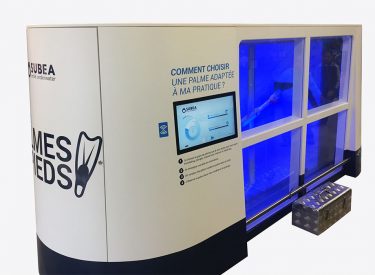

Endurance bench for in-store use by customers. Bicycle frame tests with an industrial, attractive and intuitive design.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

Combine mechanical performance with an attractive industrial design.

The bench, present in the shop, must be able to carry out, under the same conditions as in the laboratory, the same standardised test procedures (ISO/FDIS 4210 standard), with a visualisation of the tests and results that can be easily understood by a non-expert

Problematic Issues

Use of the bench directly in a shop, under the same test conditions as in the R&D laboratory, while ensuring total safety for the general public. The bench is also used by R&D teams, while ensuring total safety for the general public.

Use in a shop also means that the machine must be silent, which prevents the use of pneumatic systems.

The bench is also used by the R&D teams to develop new products.

Solution and Result

LF Technologies has designed a bench for simple and intuitive use, both in terms of mounting the bicycle frame on the machine and using the software.

Particular attention has been paid to the visibility of the frame and the display of the measurements (effort curves, number of cycles) for an uninformed public. Once the test procedure has been chosen, the cycle starts automatically after recognition of an RFID identification badge.

The frame is thus put under stress.

The first test bench for bicycle frames is already on the shelves of the French pilot shop. The quality of the tested product is thus visible in real time to the customer.

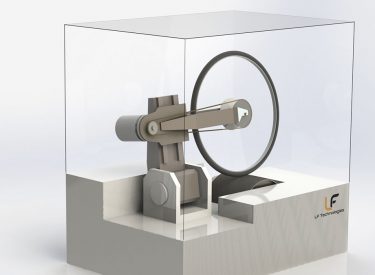

Other test benches that can be offered by LF Technologies concerning the 4210 standard applicable to cycles/bicycles.

- Static test bench for forks, wheels and tyres.

- Safety and static strength test rig for steering column.

- Static strength and fatigue test rig for saddles and seat posts.

- Vertical strength fatigue test rig.

- Brake test bench.

- Frame and fork fatigue test rig.

- Drop test rig.

All tests can also be carried out on electric bikes.

Contact our Research Department.

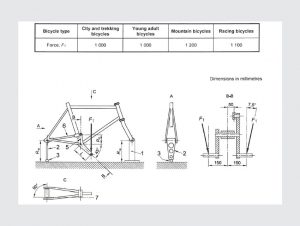

Extract from the standardisation

4 Frame test methods

4.1 Frame – Impact test (drop of a mass)

4.2 Frame and front fork assembly – Impact test (frame drop)

4.3 Frame – Fatigue test with pedalling forces

4.4 Frame – Fatigue test with horizontal forces

4.5 Frame – Fatigue test with vertical force

5 Fork Test Methods

5.1 Suspension Forks – Tyre Play Test

5.2 Suspension forks – Tensile test

5.3 Front fork – Static bending test

5.4. Front forks – Rear impact test

5.5 Front Fork – Bending Fatigue Test and Rear Impact Test

5.6 Forks Designed for Use with Hub or Disc Brakes

5.7 Tensile test for a non-welded fork

Products tested

Bicycle frames

Bike Saddle Handlebar Test

Bike Saddle Handlebar Test

Bicycle Handlebar Test

Bicycle Handlebar Test

Extract from standards 4210

Extract from standards 4210

Bicycle frame test bench test curves

Bicycle frame test bench test curves

Children’s bike helmet test bench

Children's bike helmet test bench

Adult bicycle helmet test bench

Adult bicycle helmet test bench

Fatigue tester – Pedaling force

Fatigue test bench / Pedaling force

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed by LF Technologies.