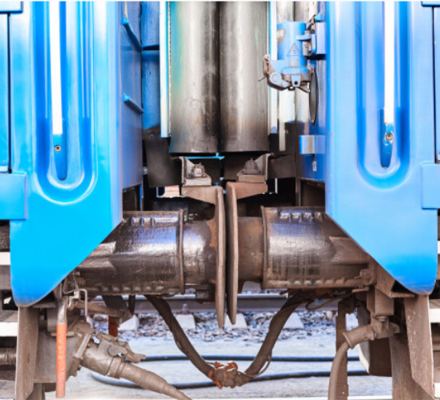

Elastomer extruder for shock absorber manufacture

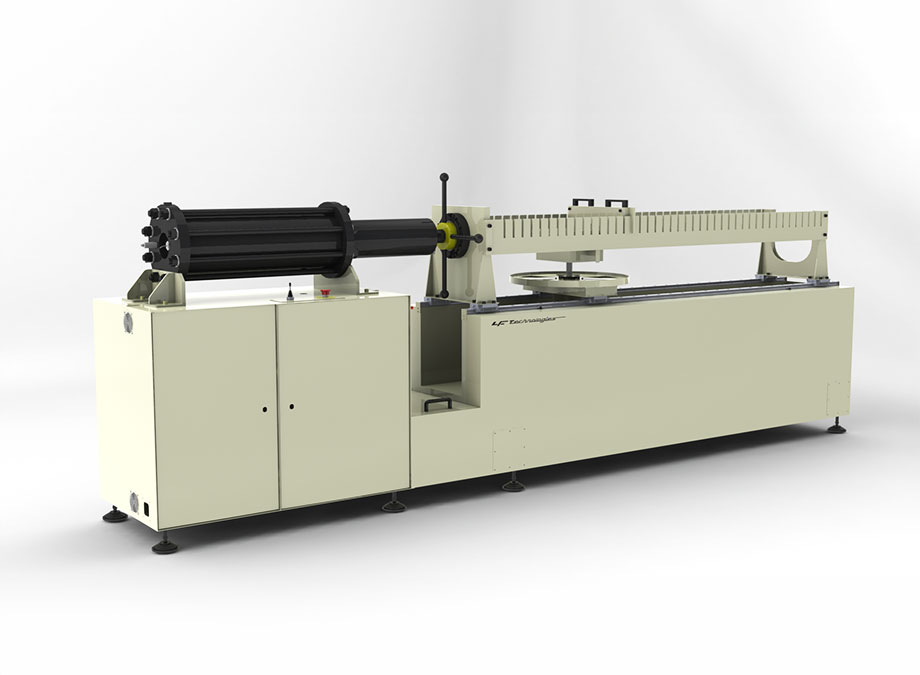

The purpose of the plodder designed by LF Technologies is to fill elastomer dampers under pressure with volume and pressure control.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is a designer and manufacturer of shock absorbers. These dampers are used in the navy, railways, defence, etc.

Main functions

Objective

Design a production bench for the pressurised filling of elastomer shock absorbers with volume and pressure control.

PROBLEMATIC ISSUES

The elastomer in the shock absorbers must be filled under high pressure (approx. 200 bar).

SOLUTION AND RESULT

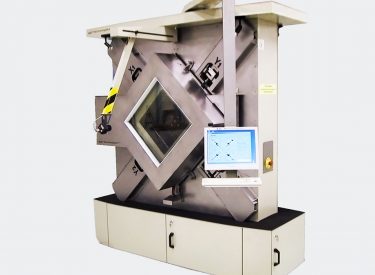

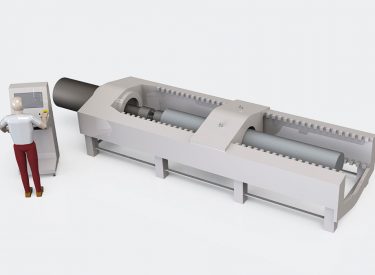

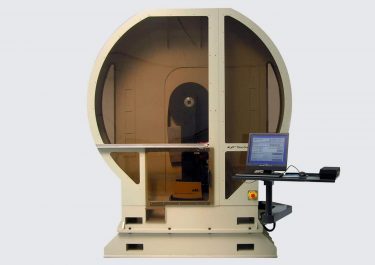

The “plodder”, a special production machine designed by our teams, is fitted with a double-acting hydraulic cylinder used as a plunger piston in a high-pressure elastomer chamber.

The chamber is filled with elastomer by the piston moving backwards, accompanied by a feed via a special high-pressure valve. Feeding is provided by an external pumping unit (piston extrusion pump).

Max. pressure injection pressure is limited to 2,000 bar.

- The operator places the shock absorber to be filled on the machine

- The elastomer chamber is filled via the extrusion machine

- The operator controls the plunger via the control panel to inject the elastomer into the shock absorber to be filled.

- Once the desired pressure has been reached, the operator moves the plunger backwards

- The operator releases the shock absorber and removes it from the machine.

- Various tools are available to fill a wide range of hydraulic dampers.

The control panel consists of a joystick connected to the software via a PC, making it easy to control the machine.

The production bench is equipped with various safety systems linked to the use of high pressure. Pressure switches keep the elastomer pressure constant and safety valves are installed to limit the risk of overpressure.

Tested product

Elastomer shock absorber

Shock absorbers are mechanical systems that use thermal energy to reduce the violence of an impact. These dampers are usually designed to control the braking of a specific mass. Elastomer, also known as rubber, is an ‘elastic’ material that can withstand very large deformations before breaking.

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.