Tensile fatigue test bench

Tensile fatigue test bench Tensile fatigue testing for product development and production monitoring. Estimation of caliper life.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

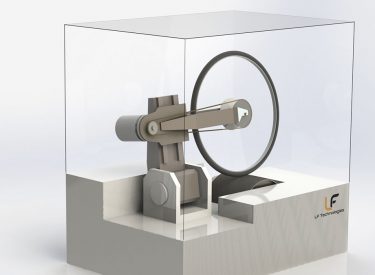

To design a laboratory facility for the qualification of stirrups, in order to measure their deformation curve and test the evolution of this deformation during fatigue tests.

Problematic issues

The fatigue bench must be able to carry out both slow-speed tensile tests and high-frequency fatigue tests with controlled force and displacement.

Solution and result

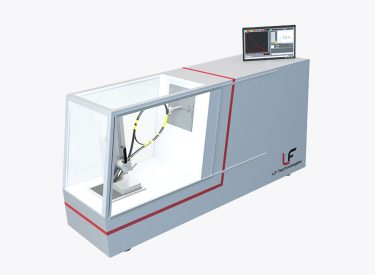

The bench designed and built by our engineers is intended for testing parts in tension, using slow cycling (tensile tests from 4 to 7000 mm/min) or fast cycling (fatigue tests at 10 Hz).

A traction jack, fixed to the frame, pulls on the caliper to be tested, which is itself attached to a tool fixed to the frame. Developed specifically for the application, this actuator provides precise control of position, force and speed, for both slow and fast cycling, and includes an integrated force measurement.

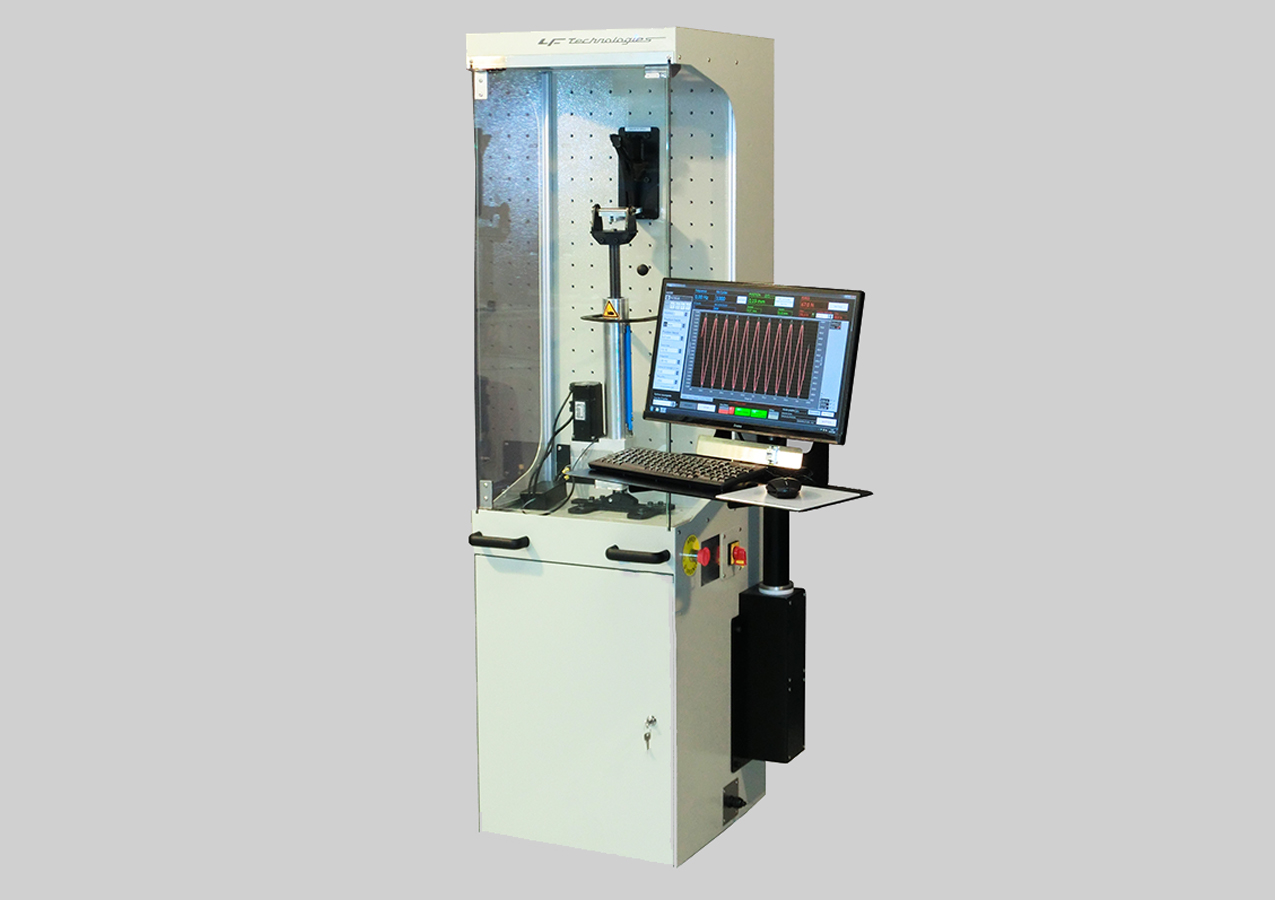

The fatigue machine is controlled by special software developed “to measure” by our programmers; The software enables “slow” traction cycling and “fast” fatigue cycling to be carried out. It displays measurements of force, position, frequency and number of cycles. It also displays force/displacement curves and allows test measurements to be saved.

To ensure operator safety in the event of breakage of the sample under test, the test chamber has side walls and a glass door. Pressing an emergency stop button stops the machine immediately.

The test bench is used to estimate the fatigue life of the caliper. Fatigue tests characterize the stirrup’s ability to withstand cyclic loading, in order to reproduce operating conditions as closely as possible.

Products testedA control PC, using software developed under LabVIEW, performs the control and measurement functions.

Horse stirrups

Horse stirrups

Tensile fatigue test on stirrups.

The test bench is used to estimate the caliper’s fatigue life. Fatigue tests characterize the stirrup’s ability to withstand cyclic loading, in order to reproduce operating conditions as closely as possible.

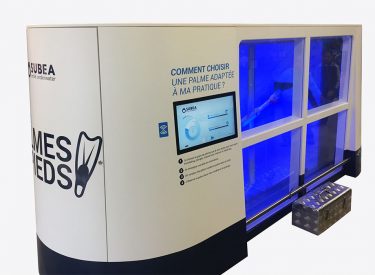

OUR KEY TEST BENCH FOR THESE TESTS Tension Compression Fatigue Bench

MFTC

Main functions

The testing machines allow to estimate the fatigue life of components and/or finished products. Fatigue tests characterize the ability of a material or product to withstand cyclical loading in order to best reproduce the operating conditions of the part.

The traction/compression fatigue test bench allows to subject parts to tensile/compression stress according to slow or rapid cycling (fatigue tests).

Operating mode

After positioning the part to be tested, the user defines a test program, consisting of a sequence of function blocks.

Each function performs trapezoidal or sinusoidal cycles controlled in force or position at an adjustable frequency.

The test is stopped automatically in the case of a rupture of the tested part.

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.