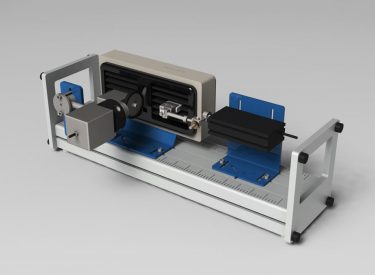

Gearbox test bench

Control test bench for rotovator gearbox. Test on the production line. Production special machine to assess your product.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is the first worldwide rotovator manufacturer.

Main functions

Objective

Design a series test bench to validate the correct operation of the gearboxes before installation on the finished product.

PROBLEMATIC ISSUES

Study a production bench for testing gearboxes. The maximum duration of the test cycle must be less than 2 minutes per product.

The test must be able to simulate resistant torques, at several speeds of rotation and with several reduction ratios.

SOLUTION AND RESULT

The design features a sit-stand working position. The test area at the front of the bench is topped by a touch-sensitive control screen.

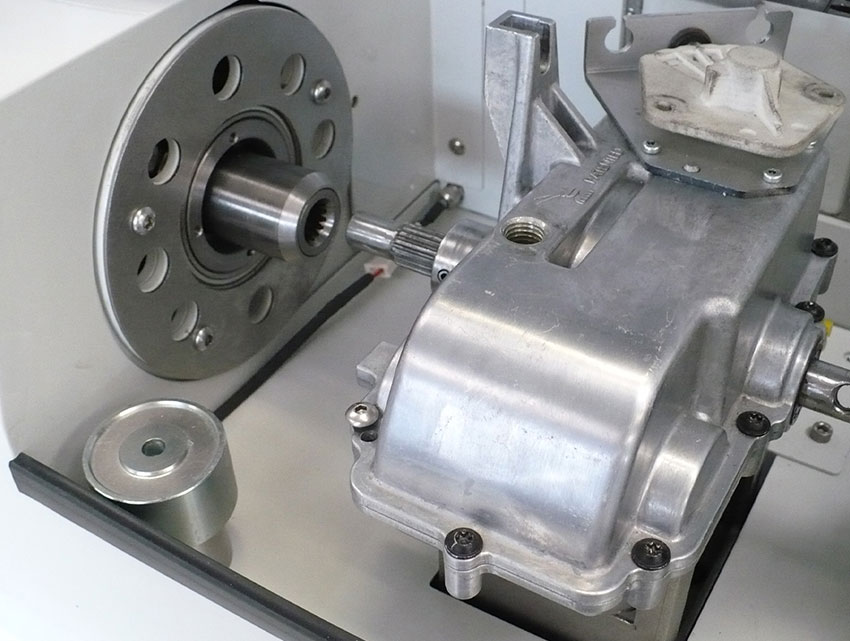

The part to be tested is placed by the operator on a support fitted with a weight sensor to check the oil level.

An active geared motor provides the power input to the gearbox under test. A geared motor simulates the resistive torque on the output stage, using high-performance speed and torque control.

The gearbox is pressurised to detect any leaks. A rotational speed is applied to the input and a torque is applied to the output. Once the test is complete, a selector changes gear and the test cycle restarts in the same way on all gears (1st, 2nd, reverse).

Conversely, on neutral positions, the test verifies that there is no couple.

The test bench is controlled by a PC equipped with custom-developed software. During the test phase, a number of data are observed:

- performance

- input torque

- operating torque

- pressure drop

- the torque measured at the output

- the speed measured at the input and output.

At the end of the tests, a unique label is printed and affixed to the gearboxes to ensure product traceability.

Tested product

Rotary hoe gearbox

A rotovator is a motorised agricultural machine specially designed for vegetable garden maintenance (working the soil in gardening or market gardening).

A gearbox is a mechanical device used to move a vehicle forwards or backwards by transmitting engine torque to the wheels via a transmission shaft with an adjustable reduction ratio.

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.