Continuous peel testing machine

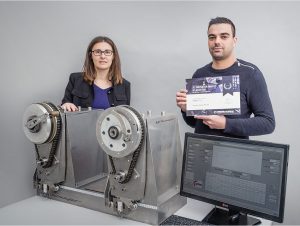

Continuous peel test bench testing adhesion and optimising the bonding process. Patented mechanical test bench that won the “testing” award at JEC America 2016.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

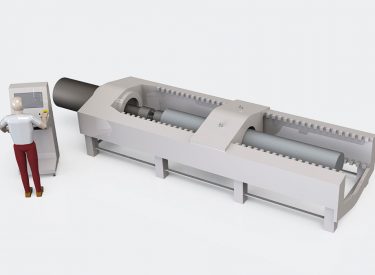

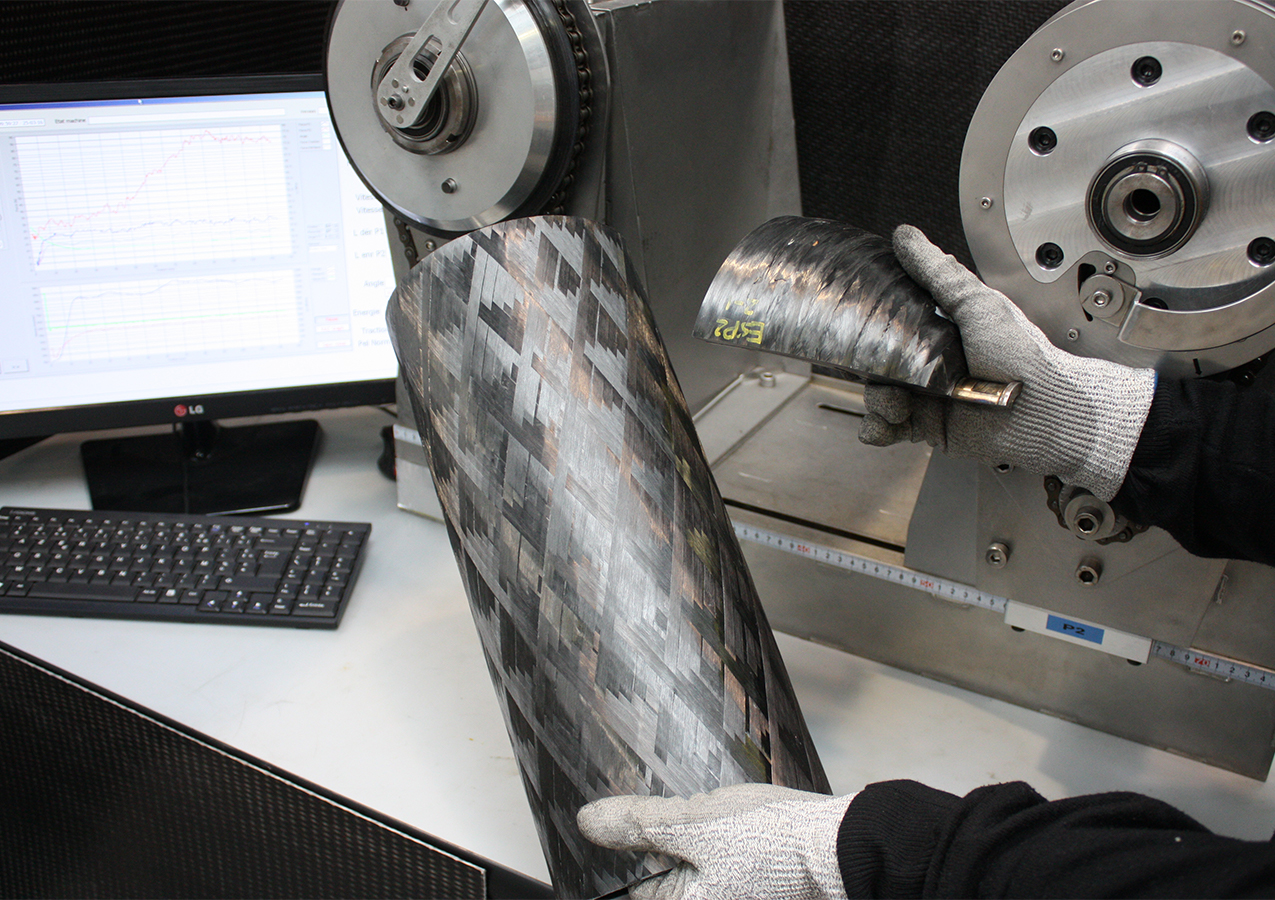

This machine is designed to perform peel tests on carbon fibres, bonded together by a bonding system whose effectiveness must be evaluated.

Problematic Issues

To carry out a continuous peel test of a sample (composite coil) in order to test and optimise the bonding process.

Solution and Result

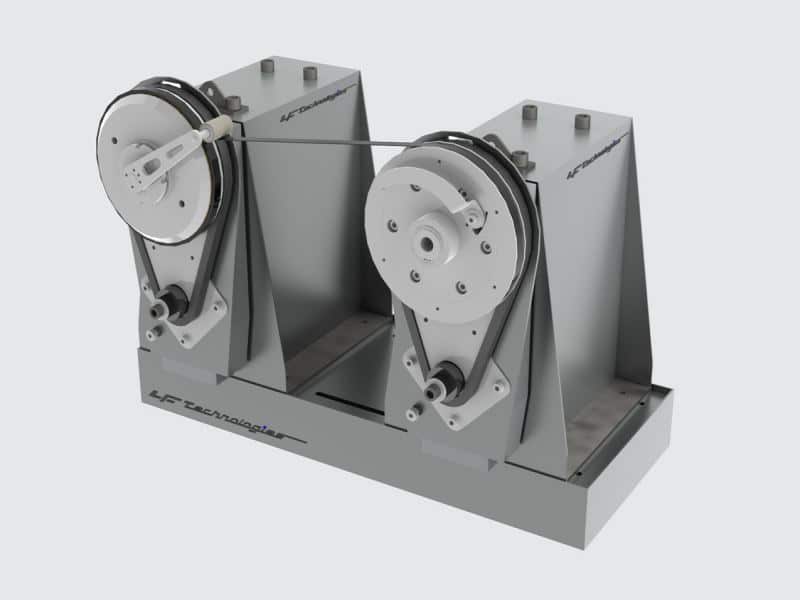

In partnership with CETIM, LF Technologies has developed a new principle of continuous peel testing (patented).

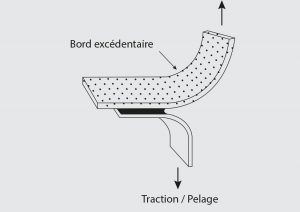

The system consists of evaluating the unwinding force of a web by pulling on it with a speed-controlled drum, while the reel itself is held in rotation by another drum whose holding torque is controlled. The angle of detachment, measured by a roller, is kept constant in relation to a set point, by the control of the holding torque.

The phenomenon used is similar to the one observed when a roll of tape is unwound, by braking the rotation more or less. The more the roll is braked, the more the peeling is tangential. If the roll is completely free, the peel is almost radial. Because of the bending fragility of carbon fibres, the angle of disbonding is kept rather tangential.

A suitable software program developed under LabVIEW permanently receives the information on the rotational position of each of the servomotors, the value of each of the measured torques, and the angular position of the disbonding angle measuring roller. The program allows the desired test parameters to be set and the curves and test results to be displayed, viewed and saved.

The realized continuous peeling bench was presented at JEC Americas in 2016 and won the award in the category “Testing”.

Products tested

Carbon composite

JEC Innovation Awards 2016 Atlanta

JEC Innovation Awards 2016 Atlanta

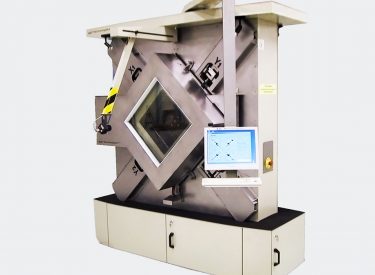

Continuous peel testing machine

Continuous peel testing machine - JEC Innovation Awards

Continuous peeling bench

The peel tester is used to continuously measure the adhesion energies of thermoplastic laminates in order to test and optimise the bonding process.

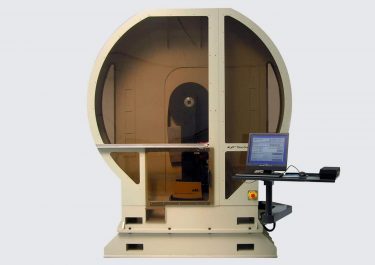

Schematic diagram of a peel test

Schematic diagram of a peel test

No preparation

The thermoplastic composite segments are transferred directly from production to the test area.

OUR KEY TEST BENCH FOR THESE TESTS MPC CONTINUOUS PEELING BENCH

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed by LF Technologies.