Peel testing machine for pipeline

The pipe peeling machine is a self-contained unit, fitted with a carrying case, for carrying out coating peel tests on pipeline pipes (gas, oil, etc.);

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is a leading European supplier of oil, gas and pipeline coatings for various on- and off-shore applications.

Main functions

Objective

Testing the pull-out strength of protective coatings on pipeline pipes. The coatings must meet the requirements of various standards, including ISO 21809 (Petroleum and natural gas industries — External coatings for buried and immersed pipelines used in pipeline transportation systems) and NF EN 12068 (Cathodic protection – External organic coatings for corrosion protection of buried or immersed steel pipes in conjunction with cathodic protection)

Problematic Issues

The peeling bench must be autonomous and easily transportable in order to carry out the tests directly on site.

Solution and Result

LF Technologies’ teams of engineers and technicians have designed a special peeling machine designed to assess the pull-out strength of pipeline pipes. The bench is completely self-sufficient thanks to its battery operation, and is easy to move around thanks to its carrying case;

The machine is fitted with a gripper which holds the end of the sample to be tested; This clamp is inserted into a Ø 150 mm reel. The machine’s drive wheels, combined with a light barrier, are used to hold the torn-off part of the sample in a radial position, without a deflection roller. Two removable side pulleys allow the machine to be strapped to the pipe if required.

A 4-button keypad is used to tighten and loosen the clamp, control drum rotation, as well as machine movement and the cycle. No tools are required, thanks to the automatic clamping system for vices, jaws or clamps. The display above shows the measured value of the pull-out force as a function of the pull-out length.

Programming, analysis and output of results, via a report ticket, are included in the carrying case. Data is exchanged between the machine and the case using a wireless link (Wi-Fi).

The peel tester’s autonomy means it can be adapted to other uses, such as testing the peel strength of conveyor drum linings or on marine worksites.

Products tested

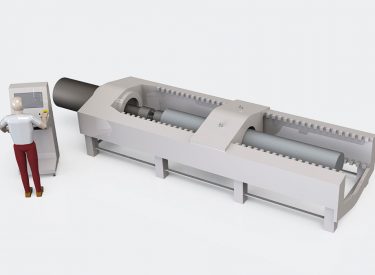

Pipeline tubes

Pipeline pipes are large diameter pipes used for the long-distance transport of certain fluids, such as fuels (oil, fuel oil, etc.) or natural gas. hey are often equipped with plastic coatings, which provide mechanical protection and thermal insulation, among other things.

Oleoduc

Pipeline pipes are large diameter pipes used for the long-distance transport of certain fluids, such as fuels (oil, fuel oil, etc.) or natural gas. hey are often equipped with plastic coatings, which provide mechanical protection and thermal insulation, among other things.

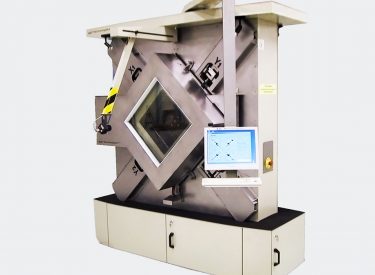

Tube peel testing machine

Tube peel testing machine

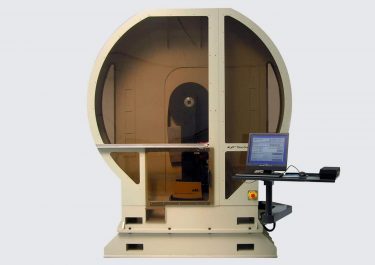

Peeling machine in carrying case

Peeling machine in carrying case

Portable machine

Easy-to-transport tube peel testing machine in carrying case.

Automatic tightening

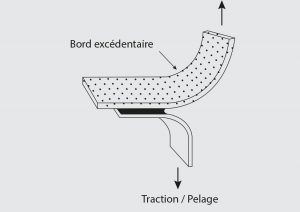

Peel test in progress

Schematic diagram of a peel test

Schematic diagram of a peel test

OUR KEY TEST BENCH FOR THESE TESTS

Peeling bench on tube

MPT

Main functions

The pipe peel tester is used to test the peel strength of protective coatings on pipeline pipes. The stainless steel machine is self-contained and powered by a standard battery. It records the peel force over a sample length of up to 200mm. The pipe peeler is also equipped with a carrying case with force and displacement monitor and report printout.

Operating mode

The machine is equipped with a gripper that allows the end of the sample to be picked up. This clamp is inserted into a Ø 150 mm reel. The driving wheels of the machine, associated with a light barrier, allow the torn-off part of the sample to be held in a radial position, without a return roller. Two removable side pulleys allow the machine to be strapped onto the tube if required. A 4-button keypad controls the clamp (un)clamping, drum rotation, machine movement and cycle.

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed by LF Technologies.