Shock absorber compression bench

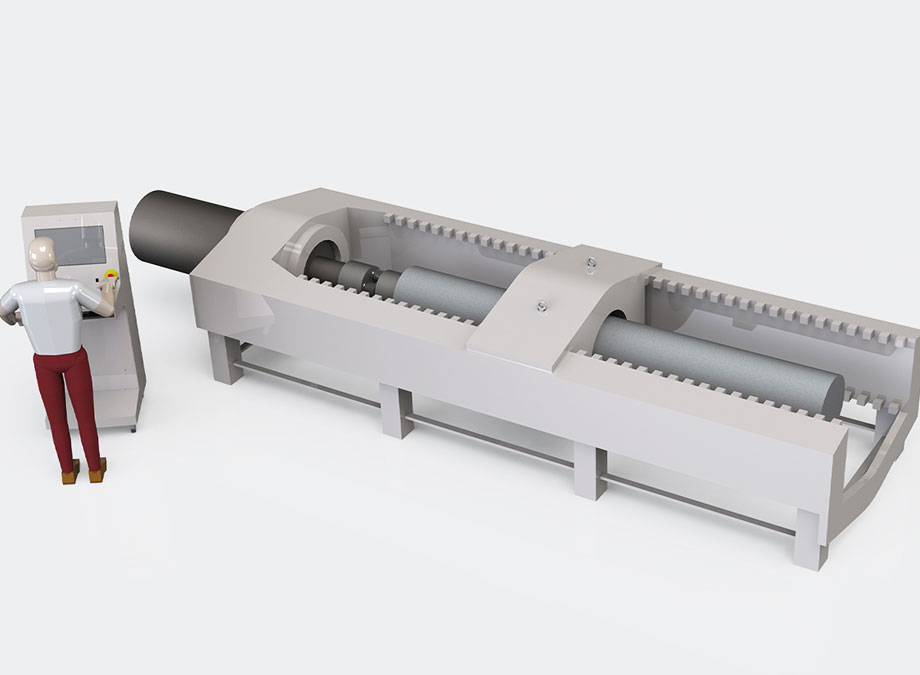

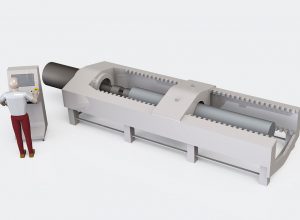

Horizontal compression test bench equipped with a hydraulic cylinder, a mobile crossbar, a remote control panel and an electrical cabinet.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client, who specialize in the design, manufacture and installation of equipment for civil engineering structures, approached us to purchase a shock absorber compression bench.

Main functions

Objective

Characterise the maximum forces supported by our customer’s earthquake shock absorbers. The compression test rig must develop a force of 3,000 kN, or around 300 tonnes. The maximum length of a test product is 3,000 mm.

PROBLEMATIC ISSUES

Design a system capable of generating a compression force of 3000 kN (300 tonnes), for shock absorbers of widely varying lengths.

SOLUTION AND RESULT

The equipment proposed and designed by our teams is a horizontal shock absorber compression bench. It comprises a compression frame, a hydraulic jack, a mobile crossbar, a remote control panel and an electrical cabinet.

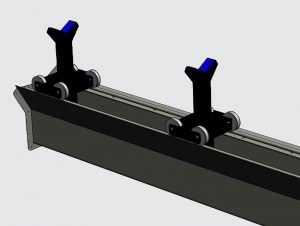

In order to reduce the cylinder stroke, LF Technologies designed a mobile crossbar system, itself made up of notches with a 100 mm pitch, enabling the length between the cylinder and the fixed part to be adjusted.

The cylinder is controlled by a hydraulic unit, which provides speed-regulated control of the compression cycle.

Tested product

Shock absorber

A shock absorber is a mechanical system designed to reduce the violence of an impact or the amplitude of its vibrations.

The building is not directly connected to the ground. It sits on pads that allow it to glide along. The shock absorber is attached between the building and the ground and, like a car, it reduces the amplitude of movements generated by earthquakes.

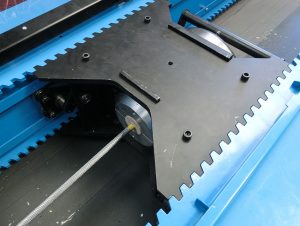

Adjusting the toothed mobile crossbar

Adjusting the toothed mobile crossbar

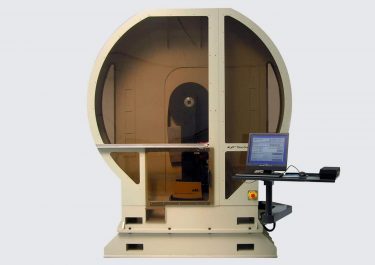

Example of seismic damper assembly

Example of seismic damper assembly

Example of seismic damper assembly

Example of seismic damper assembly

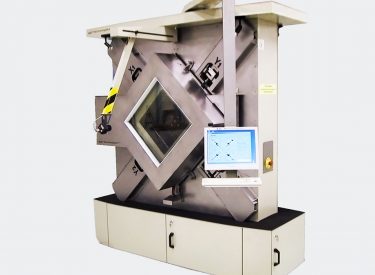

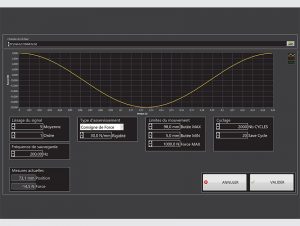

Force feedback parameter setting screen

The machine is controlled by a PC equipped with software developed specifically by our programmers. Cycles can be programmed with position or force feedback, measurements and detector status can be displayed, etc.

Product-support candles

Product support candles

Shock absorber compression bench

Shock absorber compression bench

SEISMIC DAMPER

SEISMIC DAMPER

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.