Safety strap traction bench

Aircraft webbing test bench. Tensile test to test the resistance of straps to tearing up to 1,820 daN.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

Test and characterize tearing straps, by measuring tearing force at low and high speeds, over long lengths.

Problematic issues

These tests require a high tensile force (up to 1800daN), over long lengths (up to 10m) with highly variable test speeds (from 1 to 100m/s), which implies very high tensile powers.

The system must also be capable of performing high-energy tests, even at low speeds.

Solution and result

Our engineers have created a machine capable of tearing straps from 0.4 to 10m in length at speeds of between 1 and 100m/s, with force measurement and high-frequency displacement up to 1MHz.

Test principle :

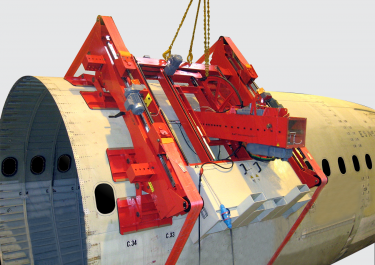

The strap is attached, on the fixed side, to a high-frequency force transducer. The other part of the strap is attached to a rung.

The machine is equipped with several winding drums of different diameters. These highly inertial drums were gradually brought up to test speed. Once the speed has been reached, a high-speed system hooks the strap bar onto the drum. The rotation of the drum pulls on the strap with very high energy (up to 1000kJ) and allows the strap to be wound up as it tears between the fixed point and the drum.

The use of different drum diameters ensures a wide range of test speeds, while retaining high energy levels. For very low speeds, the machine is also equipped with a speed multiplier for additional kinetic energy storage.

Thanks to high starting energy, speed loss during the test is minimal.

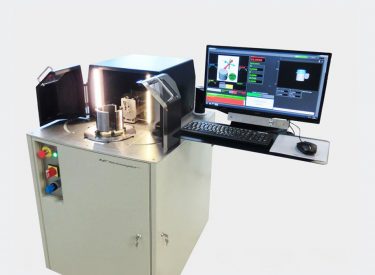

The test bench ensures user safety thanks to numerous impact-resistant covers and doors, and numerous redundant safety systems, coupled with a dedicated safety PLC.

What’s more, the machine’s fixed point is equipped with an automatic release system if the maximum force is exceeded. This principle is used to protect the machine in the event of installation of a non-compliant strap whose tearing force is beyond machine limits.

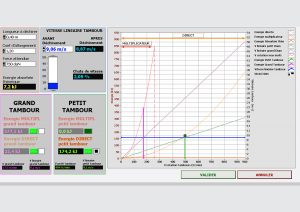

PC control is simplified by specific software for this test bench. Control can be carried out remotely, and visualization of parameters and acquisition results is presented simply with curves and tables. It saves test conditions, parameters and results.

The software is also equipped with a system for optimizing test conditions (choice of drum and test mode according to the user’s force, speed and length requirements).

Products testedA control PC, using software developed under LabVIEW, performs the control and measurement functions.

Straps

Tear straps

Tear-away straps are safety elements that help cushion a shock over a long distance. Damping is controlled by tearing (separation of 2 straps sewn together), which takes place gradually, at a controlled force. It’s the tearing force that absorbs the shock energy. These straps are used, for example, to protect people on harnesses for working at height, or to hold vehicle stop nets in place.

Tear test on straps

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.