Tile bending machine

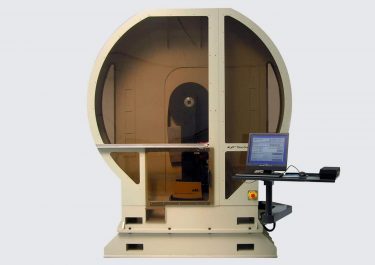

Bending machine designed to test the resistance of tiles to bending. Bending tests can also be carried out on tiles, earthenware, glass panels, etc.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is the leading manufacturer of roofing and waterproofing solutions for pitched and flat roofs;

Main functions

Objective

To design a test bench for programmable bending tests until the product breaks, with measurement of the breaking force. Bending tests are carried out in accordance with standards NF EN 491 and NF EN 538.

PROBLEMATIC ISSUES

To create a compact machine that is easy to transport and equipped with intuitive controls for setting the start position and launching automatic cycles.

Ensure a slow, controlled build-up of force, even on a fragile product that is virtually non-deformable.

SOLUTION AND RESULT

The engineers at LF Technologies have designed a compact machine that is easy to transport and simple to use.

The bending test bench enables bending tests to be carried out on roof tiles with an optimised force progression up to failure or up to the force programmed by the operator (max. 10,000 N).

The operator adjusts the distance between the two supports to suit the products to be tested (tiles, earthenware, glass, etc.);

The support tooling descends at high speed until it automatically makes contact with the sample under test. Then, once contact with the product has been made, the contact force gradually increases according to a programmable ramp.

The peak force reached is stored and displayed on the control screen.

The bending test bench can be used for several different types of product by adjusting the spacing of the supports. The intuitive control panel on the front of the bench makes it easy to use. The gradual increase in force is ideal for testing fragile materials and ensures perfect measurement of the maximum force reached at breakage.

Other products can also be tested in flexion

Tested product

Tiles

Roof tiles, which are used to cover buildings and make them watertight, are often made of terracotta, but can also be made of cement concrete. They are marketed in a number of different shapes (flat, embossed, curved, etc).

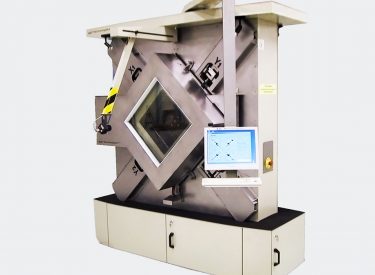

OUR KEY TEST BENCH FOR THESE bending bench TESTSMBF

Main functions

The bending test bench allows to perform bending tests of your product and/or sample with optimized force progressivity up to a break or a programmable force.

The progressivity of the increase in force is ideal for testing fragile materials such as tiles, roof tiles, earthenware, glass plates, and enables a perfect measurement of the maximum force reached during the break.

Operating mode

The operator sets the distance between the two supports.

The support tooling descends at high speed until it automatically makes contact with the product under test. As soon as the tool makes contact with the product, the pressure force increases progressively according to a programmable ramp.

The descent is carried out until the automatic detection of the break or the reaching of the programmed maximum force.

The maximum force peak reached is stored and displayed on the screen.

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.