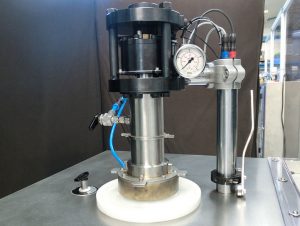

Leak test bench for valves

The transmissivity measurement bench is part of an R&D initiative to study the tightness of valves and fittings in nuclear power plant circuits.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

R&D approach: Investigate the tightness of the customer’s valves in nuclear power plant circuits by measuring liquid leakage.

Problematic Issues

The test bench must come as close as possible to the operating conditions of nuclear power plant circuits, by reproducing the same effects (metal-to-metal contact) on the cylindrical specimens.

The bench is installed in the R&D laboratory.

Solution and Result

The transmissivity measurement bench developed by LF Technologies quantifies the leakage of water, in the liquid phase, between 2 mechanically supported surfaces (test piece resting on a reference counterpart), subjected to a differential pressure, as a function of :

- the incorrect shape of the test piece

- pressure (internal and external)

- the force with which the test piece rests on the antagonist.

The test specimen is installed at the heart of the test chamber, where a push rod stresses its test face against a counterpart. A bell closes the enclosure and protects the area.

The antagonist, made of a rigid material with a flat reference surface, is applied to the face of the specimen with the shape defect. The tube is sized to provide a measure of the force applied. A highly sensitive inductive displacement transducer placed inside the tube measures its axial deformation. Axial loading is carried out by means of a short-stroke hydraulic cylinder (10 mm), with a pressure of up to 300 bar and a thrust of 150 kN.

The shape of the bell is designed to limit air retention zones. The pressure is measured in each “chamber”. A temperature sensor measures the temperature as close as possible to the leak.

Three independent plungers provide continuous flow and perform various functions, including external pressurisation, compressibility measurement, external leakage measurement and flow measurement (inflow and outflow).

Un PC de commande assure, par le biais d’un logiciel développé sous LabVIEW, les fonctions de contrôle et de mesure.

Products testedA control PC, using software developed under LabVIEW, performs the control and measurement functions.

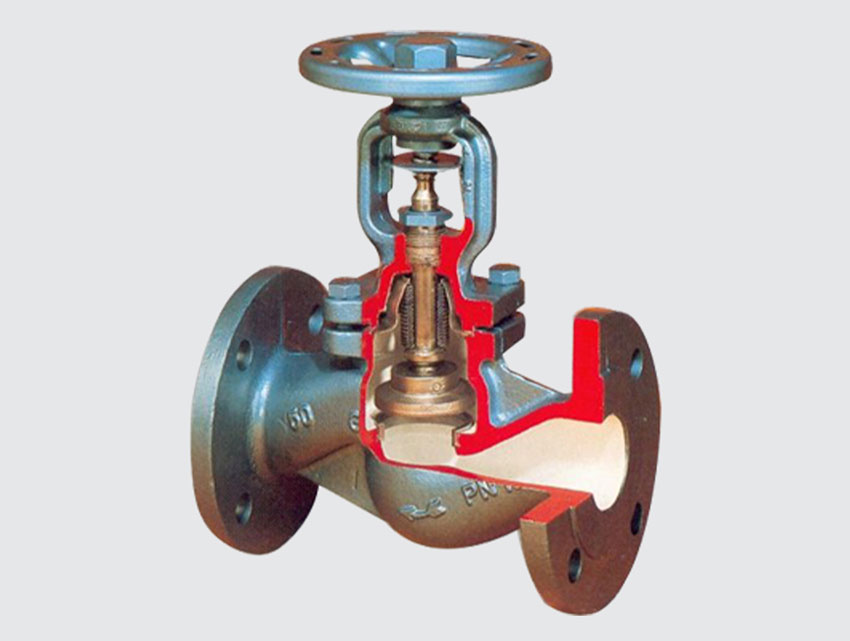

Cylindrical test tubes simulating water fittings used by the customer.

These may include valves such as steam valves, globe valves, straight-through valves, double-sealed isolation valves, etc.

Leak test bench.

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.