Mastering hydraulic testing

LEAK/TIGHTNESS TESTS

LF Technologies leak test benches are state-of-the-art tools for checking and qualifying the leak tightness of a hydraulic component or system, guaranteeing accurate results and contributing to the safety and performance of systems. Find out how our solutions raise quality standards in this field.

Cyclic pressure test

Cyclic pressure tests simulate a repetition of pressure cycles in hydraulic components or pipes. These tests are used to test the durability of a product subjected to a large number of cycles in order to assess its lifespan.

These tests can be carried out for R&D missions to improve the lifespan of a component, or by the quality department to check compliance with endurance and fatigue standards.

Burst pressure testing

Burst pressure tests are used to determine the maximum allowable pressure by gradually increasing the pressure until the product ruptures.

The progressive pressure increase of our equipment and the automatic rupture detection systems allow for automatically and precisely defining the maximum pressure reached at rupture or according to a deformation threshold

Water hammer tests

Water hammer phenomena are increasingly studied at the product design stage. LF Technologies offers various technical solutions to simulate this type of phenomenon:

- Benches that generate controlled pressure spikes to verify a component’s pressure resistance during a water hammer.

- Benches that quantify the water hammer generated by a component (e.g., closing a valve subjected to high flow).

Hydrostatic proof Test

Hydraulic proof tests are generally regulatory and used to guarantee pressure resistance in accordance with the requirements of a standard (PED for example).

By subjecting equipment to a pressure higher than its normal operating pressure, generally with water as the test medium, this procedure reveals any leaks or structural weaknesses. Essential for guaranteeing the safety and compliance of installations, hydraulic testing is a crucial step in the maintenance and validation of fluid systems.

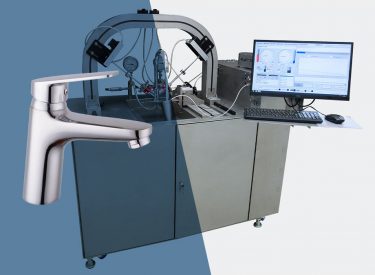

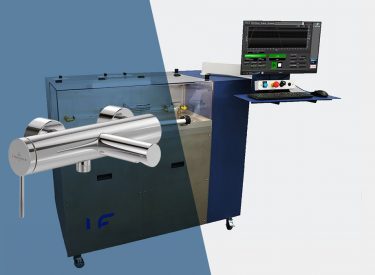

Our hydraulic test benches

LF Technologies offers a wide range of hydraulic test benches for testing all types of equipment: hydraulic components, sanitary fittings, sanitary equipment, industrial hydraulic systems and more. Whether standard, modular or made-to-measure, each rig is designed to perform reliable hydraulic tests, in line with your protocols and objectives.

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Choose a LF Technologies hydraulic test stand

Every hydraulic test stand we develop is designed to guarantee precision and reliability for your tests. Here are the main features and functions of our test benches.

1. Versatility and modularity

- Adaptability to your needs: Our hydraulic test stands can be configured to meet specific requirements, whether for hydraulic proof, endurance, adjustment or certification testing of your equipment and products. They will enable you to assess the performance, durability or quality of your products, and certify them to standards.

- Compatibility with a wide range of equipment: This modularity also makes it possible to test a wide range of hydraulic products and equipment. Our test benches can be used to test mixing faucets, pumps, valves, hoses, water heaters or more complex hydraulic systems. This guarantees broad coverage of test requirements in a wide range of industries

2. Measurement accuracy

- High-precision sensors: Equipped with a wide range of sensors, our test benches measure pressure, flow, temperature and other critical hydraulic test parameters with the utmost precision. This precision is essential to ensure that the products tested comply with international standards, and to detect leaks, pressure resistance, etc.

- Control systems: Integrated control systems ensure effective temperature and pressure control throughout the test. Our hydraulic tests benches can simulate extreme hydraulic system operating conditions, such as rapid variations in temperature or pressure, to assess the strength and durability of the components under test.

3. Automation and ease of use

- Human Machine Interface (HMI): All our test machines feature an intuitive HMI, enabling operators to set up tests, monitor parameters in real time, and analyze results. The interface is designed to be easy to use, even for inexperienced users.

- Test automation: Our test stands can carry out fully automated tests, reducing the risk of human error and ensuring perfect reproducibility of results. What’s more, they can generate test reports automatically, facilitating data documentation and analysis.

4. Safety and Compliance

- Standards compliance: Depending on your requirements and the market to which you are exposed, the hydraulic test bench is developed to meet the most stringent safety and quality standards, such as machine directives and industry-specific standards (e.g. NF EN 1111 for thermostatic mixing valves). This ensures that the tests carried out are not only accurate, but also comply with regulatory requirements.

- Integrated safety systems: To protect operators and equipment, our testing machines are equipped with safety devices such as protective elements, monitoring sensors (temperature, pressure) and emergency stop systems. These devices ensure a safe test environment.

5. Reliability and Durability

- Robust design: Our testing machines are made from quality materials that guarantee long life and reliable operation, even under high stress.

- Simplified maintenance: The benches are designed for easy service and maintenance, with easy access to critical components and built-in diagnostic systems that alert users to malfunctions or maintenance requirements.

These features make LF Technologies hydraulic tests benches essential equipment for ensuring product quality and reliability in a wide range of industrial sectors. They also guarantee strict compliance with international standards, and help optimize testing processes.

LF Technologies is

They trust us

Customer applications

Discover LF Technologies know-how through our customer applications.

Hydraulic tests benches: applications for your industry

The hydraulic test benches or hydraulic test stands we design meet the specific needs of industries that depend on hydraulic systems, or manufacturers of sanitary equipment and components. They help ensure the reliability, robustness and conformity of hydraulic products and systems. Examples of industrial applications include

1. Sanitary fittings

- Taps performance evaluation: Our test benches can be used to test the hydraulic performance of mechanical, thermostatic and other types of mixer taps, simulating real-life conditions of use. They assess thermal regulation, mechanical resistance and tightness.

- Normative compliance testing: LF Technologies designs test stands capable of carrying out tests to international standards, such as EN 1111, to ensure that products meet safety and performance requirements.

2. Automotive sector

- Pressure resistance tests: Hydraulic and hysrostatic components used in braking systems, such as hoses and fittings, are subjected to high-pressure tests to ensure that they can withstand rigorous operating conditions without failure.

- Ageing simulations: The benches can be used to simulate accelerated conditions of use, reproducing years of use in a short space of time. This makes it possible to assess the resilience of components in the face of thermal and pressure stresses.

3. Aeronautics

- Validation of hydraulic systems: Test rigs are used to test complex aircraft hydraulic systems, such as flight control systems, to ensure their operation in environments subject to wide variations in pressure and temperature.

- Safety and compliance testing: To meet the stringent standards of the aeronautics industry, hydraulic test bench verify the compliance of critical components, guaranteeing the safety and efficiency of systems in operational conditions.

4. Energy and Nuclear

- Testing valves and hydraulic components: In nuclear power plants and other energy facilities, the reliability of hydraulic systems is essential. Hydraulic test rigs are used to test the pressure resistance, tightness and strength of valves and other hydraulic components under simulated operating conditions.

- Simulation of failure scenarios: The benches can also recreate failure scenarios to analyze the behavior of systems under extreme conditions, helping to develop more robust solutions.

Advice from our experts

Would you like to find out more about hydraulic test stands ?

Find out everything you need to know and much more !

What methods are used to test pipes in the building industry?

Who are the test bench users ?

What are the most important tests on sanitary hoses ?