How long does the mechanical endurance testing of valves according to the EN standard last ?

The EN standard imposes regulations on manufacturers in terms of the mechanical endurance of valves. For the most common valves, we’ll show you how the test works. How long does the test last ? How are test bench tests carried out ? And what are the expected results ?

If you would like to know more about the various tests performed on taps when they are put on a test stand, please see our article on the main test points of a sanitary tap.

The information given in this article is for information purposes only and should not be used as a substitute for an official document on valve standards.

SOMMAIRE

Mechanical endurance of single and mixing taps – EN 200

Operating element

Principle of the test

The principle of the test is to check the actuator by subjecting it to a number of opening and closing movements after setting the water temperature/pressure to a specified value.

How long does the test take ?

For a single valve (i.e. with one handle for cold water) or a mixing valve, 200,000 opening and closing cycles at a specific speed will be required. The cycle will last approximately 7 seconds and will take the following form

- opening of the valve actuators (about 1 second)

- 2 second delay in the open position

- closing of the valve (about 1 second)

- 3 second delay in the closed position

It takes approximately 389 hours, or 16 days, to complete the endurance test on a single valve.

Checks following the test

Make sure that none of the parts are defective and that the valve still meets the tightness criteria. This means that there are no leaks upstream or on the outlet.

Mechanical endurance of self-closing taps – EN 816

Operating element

Principle of the test

The principle of the test is to subject the valve to a number of operations in order to ensure its long-term behaviour.

How long does the test take ?

For a simple valve

The simple self-closing valve will undergo 210,000 cycles. A cycle corresponds to the opening of the flow by pressing the supply button, waiting for the end of the flow + 5 seconds. The temperature must be below 30°C.

For a mixing faucet

During 70,000 test cycles, the following operations must be carried out:

Start: Temperature control device in middle position, mixing valve closed.

- Open and then release.

- Move the temperature control to the cold water position in about 1.5 seconds.

- Wait until the end of the flow.

- Wait for 5 seconds.

- Open and then release.

- Move the temperature control to the hot water position in about 3 seconds.

- Wait until the end of the flow.

- Wait for 5 seconds.

- Open and then release.

- Move the temperature control to the middle position in about 1.5 seconds.

- Wait until the end of the flow.

- Wait for 5 seconds.

In one test cycle, there are 3 movements of the temperature regulator. The valve will therefore undergo a total of 210,000 cycles (pressure on the actuator + flow + 5 second delay).

If we take 7 seconds of flow in the case of a hand-washer, we obtain a test that will last approximately 758 hours / 31.6 days. This calculation is not valid for a shower, for example, which will require a longer flow time..

Checks following the test

During the test, no breakage of components, disassociation of the seat or inability to operate the fitting should be observed.

Mechanical endurance of mechanical mixing taps – EN 817

Mechanical endurance of the operating element

Principle of the test

The actuator is made to perform a large number of movements, with a time delay, under specific conditions of pressure and temperature of cold and hot water.

How long does the test take ?

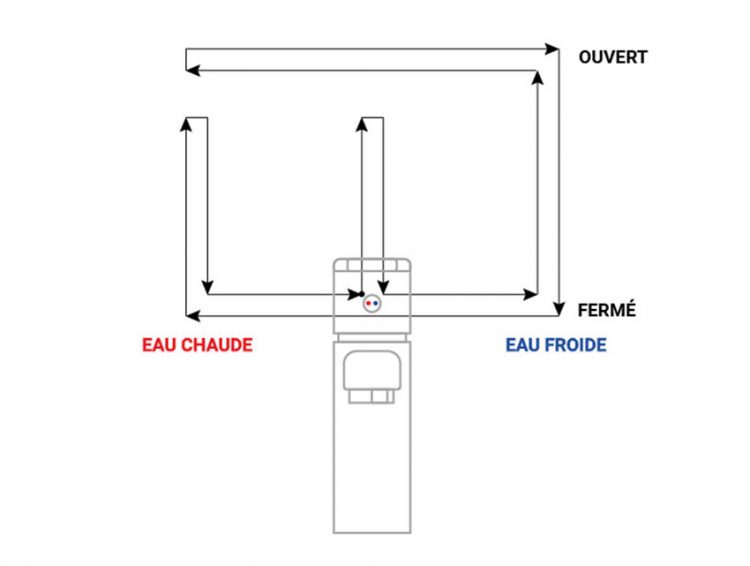

The mechanical mixing valve will undergo 70,000 cycles, in rectangular or triangular movement.

For a rectangular movement, a cycle consists of three opening and closing movements, followed by a hot/cold water return:

- opening – closing in medium position

- opening in cold position

- move to hot water position

- 5 second delay

- return to cold water position

- 5 second delay

- cold water shut-off

- move to hot water position

- opening – closing in hot water position

- return to medium position

In the case of a rectangular movement, the test of the mechanical mixing valve will last around 583 hours / 24.3 days.

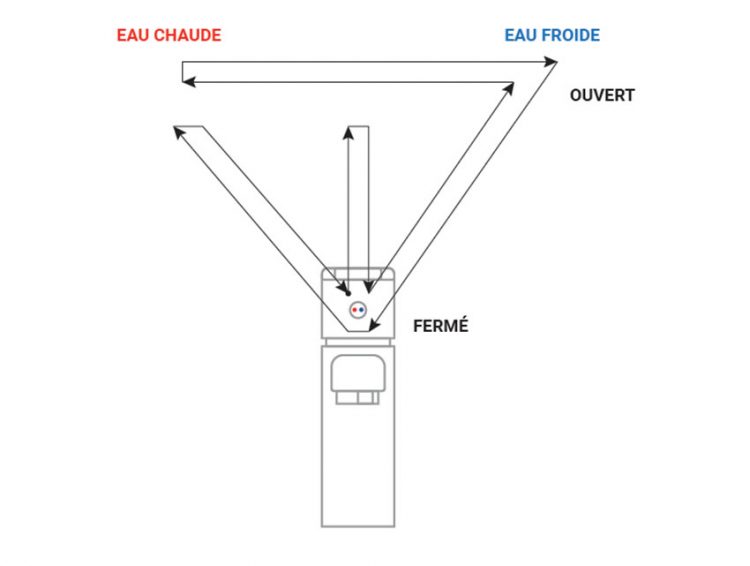

For a triangular movement, a cycle consists of three opening and closing movements, then a hot/cold water return:

- opening and closing in medium position

- full opening to cold water position

- movement to hot water position

- 5 second time delay

- move to cold water position

- 5 second time delay

- close to medium position

- open to hot water position

- closing to medium position

In the case of a triangular movement, the test of the mechanical mixing valve will last around 428 hours or 17.8 days.

Checking points after the test

During the test, there must be no parts that break, jam or leak. The operating torque must not exceed 3 Nm. The valve must always meet the tightness criteria.

Do you have a project ? Contact our test bench experts

Why choose certified products ?

The benefits of certification

Certified products are a guarantee for the consumer, and a mark of commitment for both the manufacturer and the certifier.

The advantages are many:

- Propose a product that meets market expectations and the profession’s best practices

- Provide proof that your products comply with current standards

- Strengthen your customers’ trust and acquire new ones

- Increase quality within your company

- Set yourself apart from the competition

- Reaching new markets

Certification guarantees product performance and quality stability. Manufacturers are obliged to continuously monitor their production processes, and to record the results in registers made available to the AFNOR inspection body.

Test benches for sanitary equipment

The products that claim the NF mark are tested and controlled on a laboratory test bench to ensure their compliance.

Our hydraulic test benches are designed for sanitary fittings testing and comply with sanitary fittings certifications and standards.

Performance test benches, endurance test benches and test benches: all our test benches can be used to carry out hydraulic tests on your sanitary equipment.

Our hydraulic performance test benches can test several types of products (cartridges, mechanical or thermostatic valves, etc.) and meet the needs of manufacturers, distributors or test laboratories.

CSTB uses our hydraulic test benches to check the performance of pipes, flush cisterns and heating cables, as well as a wide range of sanitary fittings. Hydraulic test benches guarantee the conformity of your product’s characteristics and its added value on the market.

To find out more about standards and certifications, read our article on standards and markings for faucets in France and around the world.

Mechanical endurance of thermostatic mixing taps – EN 1111

Operating element

Principle of the test

The test consists of subjecting the actuator to a specified number of openings and closings.

How long does the test last ?

The actuator is subjected to 200,000 opening and closing cycles at an opening of at least 75% of its travel.

Test cycle sequence:

- opening of the actuators to at least 75% of their travel (2 seconds)

- time delay of 1 to 2 seconds

- closing of the control elements (2 seconds)

- 2 to 3 seconds delay

The test time is estimated at 500 hours or 20.8 days for the sequential control devices.

Checks following the test

Throughout the test, there must be no malfunction of any component. After 50,000 opening and closing cycles, the thermal performance must still comply with the requirements of the standard. After 200 000 opening and closing cycles, the tightness of the thermostatic mixing valve shall meet the required criteria.

Endurance test for shut-off valves

Principle of the test

This test consists of subjecting the combined opening/closing and reversing device to a specific number of openings and closings.

How long does the test take ?

The shutter-reverser shall be subjected to 100,000 cycles for each flow mode.

The following steps define a test cycle:

- open the flow to outlet 1 and remain in this position for 1 to 2 s

- close the valve and remain in this position for a holding period of 2-3 s

- open the flow to outlet 2 and remain in this position for 1-2 s.

- Move the system to the closed position with zero flow and remain in this position for a holding period of 2 to 3 s.

The result is a test that should last approximately 500 hours or 20.8 days.

Checks following the test

During the test, no failure of any component should occur. After the 100,000 opening and closing cycles, check the tightness of the thermostatic mixing valve by performing the required tests.

Thermostatic element

Principle of the test

The test consists of subjecting the thermostatic element to a number of operating cycles.

How long does the test take ?

The temperature control elements shall be subjected to 50 000 cycles. One cycle corresponds to the movement from the start position to the end position and back to the start position. During the cycle the temperature control element is moved between the cold and hot water positions for 80-90% of the possible travel, without going to the stops, and remaining in the stop positions at the end of the movement for at least 5 s.

The test of the thermostatic element will last approximately 194 hours or 8.1 days.

Checks following the test

During the test, no failure of any component should occur. The operating torque of the actuator must not exceed 1.5 Nm. After the test, the mixing valve shall be tested for leakage and thermal performance.

Electronically controlled opening and closing taps – EN 15091

Moving parts

Principle of the test

The valve will be subjected to many operating cycles to see its long term behaviour. The valve will be activated and allowed to close according to the manufacturer’s instructions.

How long does the test take ?

For a single valve

The valve will undergo 200,000 cycles. If the valve is battery operated, the battery can be replaced during the test and the number of battery changes should be noted. The water pressure should be static.

The cycle corresponds to an activation of the sensor according to the conditions of use and wait for the end of the flow.

For a mixing faucet

The electronic mixing valve will undergo 70,000 cycles. If the valve is battery operated, the battery can be replaced during the test and the number of battery changes should be noted. The water pressure should be static.

A cycle is defined as :

- activating the tap in neutral position, during the flow delay set the temperature control lever to the cold position and wait for the tap to stop flowing.

- wait 5 seconds with the mixer off.

- turn the tap to the cold water position, during the flow time, turn the temperature control knob to the cold water position and wait for the mixer to stop flowing..

- wait 5 seconds with the tap off

- turn the tap to the hot water position, while the water is flowing, turn the temperature control knob to the neutral position and wait for the water to flow out.

- Wait 5 seconds with the tap off.

The duration of the test will depend on its application, for example, for a hand-washer with a flow time of approximately 7 seconds, we are at 758 hours or 31.6 days. But the flow time will not be the same for a shower tap which will require a longer flow time.

Checks following the test

Throughout the test, check that no components are broken, check that the sensor is working properly and ensure that the fitting continues to function correctly. The valve must still meet the leakage criteria.

Endurance of manually operated diverter valves

Principle of the test

The testing of diverter valves is similar for all types of valves. The diverter is subjected to a set number of operations, with the valve being supplied successively with cold and hot water, in order to check its efficiency over time, taking into account the water temperature.

How long does the test last ?

The diverter must undergo 30,000 cycles, 1 cycle corresponding to a round trip between the closed and open position. For the duration of the test, the valve must be supplied with hot and cold water alternately at intervals of about 15 minutes.

- with the diverter in position outlet 1, let the water flow through the outlet for 5 seconds

- move the diverter to the outlet 2 position

- let the water flow out of outlet 2 for 5 seconds

- close the supply to the thermostatic mixing valve with the quick-closing valve and let the diverter return to the outlet 1 position, then reopen the supply.

A manually operated changeover test will take approximately 116 hours, or 5 days.

Checks following the test

Throughout the test, there must be no malfunctions such as blockage, failure of the changeover switch to trip, leakage, etc. The test must be carried out in accordance with the relevant regulations. It must also always comply with the standards in terms of tightness.

Mechanical endurance of swivel spouts

Principle of the test

The spout test is similar for all types of taps. The principle of the test is to supply the tap with cold water and to make it pass a number of cycles in the form of a back and forth movement, in order to check how the spout reacts to prolonged use. A mass of (1 ± 0.1) kg is applied to the spout of the tap, it must be sufficient to apply a bending torque to the spout.

How long does the test last ?

The spout is subjected to 80,000 cycles. One cycle represents a rotation through 90% of the possible spout tilt range and a return to the initial position.

It is an automatic machine that reciprocates the spout at a rate of 15 cycles per minute.

The endurance test for a swivel spout therefore takes approximately 89 hours, or 3.7 days.

Checks following the test

During the test, no deformation, leakage or breakage of the spout, the connecting device or the assembly should occur.

For more information on endurance testing times for sanitary faucets, contact us and discover our range of test benches for endurance testing

Discover other articles and tips

What methods are used to test pipes in the building industry?

Who are the test benchusers?

What are the most important tests on sanitary hoses ?