How to test a water heater’s pressure resistance?

A water heater or hot water cylinder is affected daily by pressure and temperature cycles. They must be tested to ensure their resistance to these conditions of use. Pressure resistance must be checked to ensure that the heater is not leaking, bursting or otherwise damaged. The purpose of the cyclic pressure test is to assess the durability of the water heater, in particular the integrity of its seal and the resistance of the tank lining over time.

SOMMAIRE

What is the standard for testing water heater pressure resistance?

The “NF EN 12897+A1” standard is the benchmark for hot water cylinder testing. This standard, whose full title is “Requirements for indirectly-heated storage water heaters not open to the atmosphere”, comprises a multitude of tests to validate the correct operation of a water heater: temperature setting, tank pressure resistance, heater pressure resistance, test pressure, pressure cycling, etc.

How to demonstrate water heater compliance?

To prove their compliance with European standards, water heaters must undergo a series of tests, with strict conditions and values to be met. These tests take several forms:

- R&D tests: These tests provide information on the water heater’s fundamental attributes (real capacity, power, durability, etc.). These tests are carried out on a prototype model of water heater before it goes into series production;

- Factory production control tests by the manufacturer: Either systematic tests on all products, or tests on products taken from the production line (to ensure that the manufacturing process remains compliant).

Different types of tests:

Proof test :

A proof test consists of applying a specific pressure for a given time. This test ensures that the water heater is mechanically sound. In accordance with standard NF EN 12897+A1, the cylinder must withstand a pressure 2 times greater than its working pressure for a period of 10 minutes. The balloon passes the test if, at the end of the test, it shows no leaks or cracks.

Cycling test (durability) :

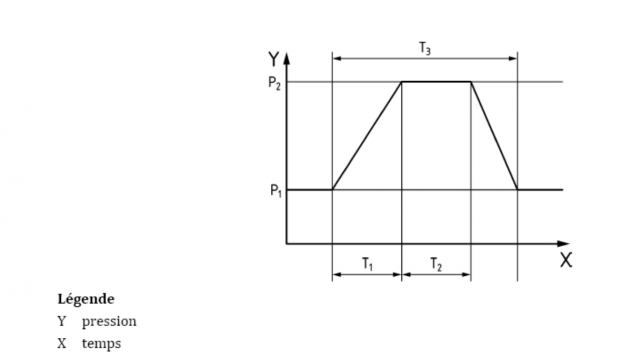

The purpose of a cycling test is to subject the water heater to pressure cycles representative of its normal use throughout its service life. The tank is subjected to a minimum pressure (P1) and then a maximum pressure (P2) with a rise time (T1), a holding time (T2) and a complete cycle (T3) defined by the standard.

Depending on the type of water heater (with or without expansion vessel), pressure cycles are applied between 20,000 and 100,000 times with a maximum pressure (P2) ranging from 1 to 1.5 times the water heater’s working pressure.

Factory Production Control Tests

Once the water tank has been assembled, it undergoes two systematic tests:

- Internal pressure: the vessel is filled with a liquid (usually water) and subjected to a pressure corresponding to 1.3 times the working pressure of the finished product. If the test reveals any leaks, the balloon must either be repaired or scrapped.

- Sealing: the vessel is pressurized (internally or externally) with a gas (usually helium). The unpressurized side is fitted with a sniffer to measure the amount of gas escaping. As with the water test, if leaks are detected, the balloon requires either repair or disposal.

NB: Because helium has finer particles than water, it can detect finer leaks and cracks.

Do you have a project ? Contact our test bench experts

What precautions should be taken when pressure testing a water heater?

Pressure testing is a simple method of ensuring repeatable results. But pressurizing a large volume is not without risk.

In the case of water, where compressibility is low, pressurization stores little energy. The main risk in water testing is the projection of water through a leak or crack. If this leak isn’t properly anticipated, water can splash onto electrical parts or the floor, causing people to fall.

In the case of a gas, where compressibility is high, pressurization stores a lot of energy. For example, with air, to obtain 7 bar, you need to inject 7 times the volume of air to reach the pressure. This compressed air acts like a spring or elastic band, trying to return to its original shape. In the event of a part breaking, it may be projected. It is therefore necessary to install protective devices on the benches used for pressure testing.

Discover the LF Technologies cyclic pressure test application for hot water cylinders here

What other tests validate a water heater’s compliance with EN 12897?

As already mentioned, NF EN 12897+A1 does not only cover pressure testing. These other tests are mainly carried out during the design phase of a water heater, or to validate the manufacturing principle.

Various measurements are carried out to establish the tank’s performance, enabling the technical data sheet to be determined (the data sheet that enables the user to select the water tank best suited to his or her needs).

These include the actual capacity, i.e. the maximum volume the hot water cylinder can store.

There’s also the hot water capacity, i.e. the quantity of water the heater is able to supply at a temperature at least 30°C higher than the cold water.

Temperature tests are also used to determine heating power, efficiency and temperature maintenance of the heated water.

Water heaters can be fitted with accessories to ensure proper operation:

- Expansion valve (NF EN 1491),

- Expansion group (NF EN 1488),

- Safety valve (NF EN 1489),

- Safety group (NF EN 1487),

- Backflow protection (NF EN 1717),

- Non-return valve (NF EN 13959),

- Pressure reducing valve(NF EN 1567) …

All these accessories are also subject to standards, ensuring their proper functioning. In some cases, they can be tested on the same bench as the water heater, or on specific benches to meet the requirements of the relevant standards.

In short, water heaters marked “NF EN 12897+A1”, whose operation is totally transparent to most users, are appliances that have undergone extensive testing to ensure optimum operation and total safety.

Discover other articles and tips

What methods are used to test pipes in the building industry?

Who are the test benchusers?

What are the most important tests on sanitary hoses ?