Hydraulic test bench : principle and operation

Widely used in industrial processes, the hydraulic test bench is an essential system in the development of a product. To guarantee the reliability and safety of hydraulic installations and systems, the control and testing process is essential. The test bench ensures that a product is properly industrialised by putting it into use.

SOMMAIRE

What is a hydraulic test bench ?

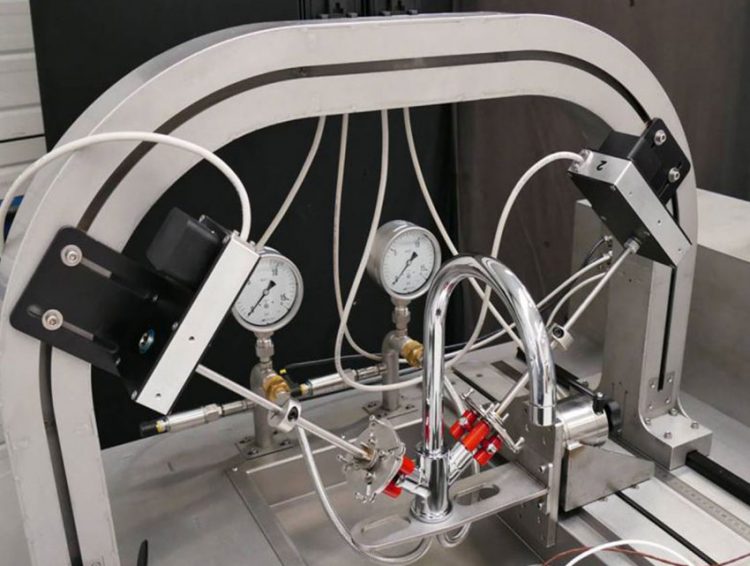

The hydraulic test bench is essential in the industrialisation of products. Also known as a “test bench”, a hydraulic test bench is a hydraulic system that allows a product to be put into use in order to observe and measure its behaviour.

Widely used in industry, the hydraulic application test rig verifies and/or validates product functionality throughout the manufacturing process. It allows to determine the hydraulic and mechanical performances of the hydraulic networks and the equipments which compose it.

It can, for example, validate the technical characteristics of taps, mixers, flushes or shower columns, in the case of a test bench for sanitary fittings. Industrial test benches are also used in many other applications, for example in the automotive, nuclear, construction and aeronautics industry.

The tests performed vary according to the nature of the product to be tested. Test benches are often custom designed by manufacturers and are adapted to each product range.

What are the different types of hydraulic test stands ?

There are several types of test benches depending on the nature and life cycle of the product to be tested:

- Performance test bench, or “characterisation test bench”: this allows the hydraulic performance of a product to be measured and adjusted. Hydraulic performance test benches are used to verify or define the maximum technical use characteristics of a product according to various criteria: flow rate, pressure, temperature, tightness, sensitivity, etc.

- Endurance test bench, also called fatigue test bench: it is used to check the life and reliability characteristics of a product. he number of test cycles can reach several million (flow rate, pressure, temperature) under variable atmospheric and climatic conditions.

- Control test bench, or “validation bench”: it verifies and validates the technical characteristics of a product during the production phase. The test bench makes it possible to check that the product’s performance meets the design specifications before it is marketed.

Hydraulic test benches are used to test the hydraulic components of sanitary and industrial equipment in accordance with the procedures in force, the standards or the certifications.

Faucets, taps, mixers, valves, pumps, hoses, sanitary and industrial equipment are tested by certified bodies such as the CSTB before and/or after marketing. The standards and certifications provide the assurance that the product meets the quality, performance and safety criteria.

The tests carried out make it possible to evaluate the following characteristics:

- waterproofing

- hydraulic and mechanical performance

- flow rate

- resistance to wear and tear

- acoustic performance

The performance of a hydraulic test bench is defined by several criteria: simplicity, technology, optimisation and reliability. The deployment of several skills (mechanical, computer, electronic…) is essential for the development of an industrial test bench.

A hydraulic test bench is developed according to very precise processes to guarantee the optimal industrialisation of the product. Various analyses are carried out upstream: value analysis, functional analysis and needs analysis. The design of the test bench also takes into account standards and certifications.. Drawings, dimensioning calculations, simulations and the choice of design are necessary for the design of the test bench.

Do you have a project ? Contact our test bench experts

How does a hydraulic test bench work ?

A hydraulic test bench can be semi-automatic or automatic. A semi-automatic test bench guides an operator to carry out the measurements, whereas an automatic test bench carries out the test automatically and autonomously.

Automatic hydraulic test benches are controlled by a PC via software that runs various scenarios: test temperature, product position in relation to an instrument. The software records the results of the calculations and measurements, then publishes the results in a file.

o optimise the performance of a test bench, the software used must be easy to use, and the interface must be intuitive and ergonomic. In the context of an industrial process, the user interface that connects a person to the test bench is called the Human Machine Interface (HMI).

In the production phase, the test bench is assembled, and a technical file is drawn up to accompany it. Adjustments are made to ensure the quality of the hydraulic test bench.

Manufacturers benefit from many advantages by carrying out automatic tests. Testing reduces errors and cuts down on time-consuming manual tasks. Companies benefit from the economic advantages as well as from optimised productivity.

LF Technologies test benches

An expert in the field of high precision engineering, LF Technologies designs and manufactures hydraulic test benches for sanitary and industrial equipment and components.

The LF technologies teams are able to design a tailor-made hydraulic system adapted to your needs and specifications. The hydraulic test benches allow all types of tests to be carried out (tightness, pressure, performance, endurance, etc.) and guarantee compliance with the standards and certifications in force.

The range of standard hydraulic test benches that we offer is modular and can therefore be adapted to all the requirements of your specifications. Ergonomic and easy to use, thanks to dedicated HMIs, our test benches provide you with optimal user comfort for :

- Control quality in production

- Optimize your R&D products

- Obtain certification to French or international standards or quality marks

The accuracy and reproducibility of the results obtained will help you to analyse the behaviour of your products. Our test benches are part of a continuous improvement and certification process for your products.

For the valve, automotive, aeronautical or nuclear sectors: our test benches meet the highest technical requirements and assist you at every stage of the process in an optimal manner.

Discover other articles and tips

What methods are used to test pipes in the building industry?

Who are the test bench users ?

What are the most important tests on sanitary hoses ?