Who are the test benchusers?

SOMMAIRE

First of all, what is a test bench?

A test bench is a system or installation for testing a product under the conditions it might encounter in use.

The test bench is used to adjust and parameterize the various situations that the object may encounter.

This makes it possible to measure product performance and verify its behavior under defined test conditions.

Test benches are widely used in all fields:

- Hydraulics : sanitary and industrial fittings, water heaters, pumps, piping…

- Mechanical: mechanical strength of building products(tiles, panelling, windows, etc.), aeronautical components, automotive components, etc.

In all areas of industry, there are different types of test bench users :

Firstly, manufacturers who use test benches to validate the design of new products and check the conformity of their series production.

Secondly, retailers who use the benches to check the conformity of their supplies, or to demonstrate them to the public.

Last but not least, certification bodies(CSTB, KIWA, LNE , for example) to check that products on the market comply with current standards and quality marks.

Let’s go into a little more detail and see how useful a bench is for each of these types of user.

Manufacturers and their use of test benches

A manufacturer’s test bench can be used in four different ways:

- The manufacturer wants to try out a product for a “functional” test.

This type of testing is often found in research and development departments.

The bench is used to measure the characteristics of a future product and its long-term performance.

The aim here is to check that the product meets its development specifications.

It also allows you to check the reliability of new product releases. - The manufacturer uses a laboratory bench: The aim?

Test the product on a bench to check that it meets the requirements (standards, quality mark or technical data sheet specifications). - The manufacturer uses a bench to carry out “unit” tests: each manufactured “unit” is tested on the production line.

This test ensures that all manufactured products comply with one or more of the characteristics specified in the product data sheet.

If the product does not pass the test, it is scrapped. - The manufacturer carries out a so-called “sampling” test : the test is performed on a few manufactured samples (“taken” from the production line).

The aim of this type of test is to use a test bench to check that the characteristics of mass-produced products do not deteriorate over the course of long-term production.

To do this, products are taken at random from the production line according to a predefined rhythm, and a test is carried out to check that the system is operating correctly. - Last but not least, it can be useful for sales staff at a showroom or trade fair touse a test bench to demonstrate the quality of their product.

Retailers and their use as test beds

Resellers can use a test bench to ensure that the products they source comply with specifications, standards and legislation.

A dealer’s service department can also use a test bench. In this case, the test bench helps to understand the cause of the problem encountered by the user.

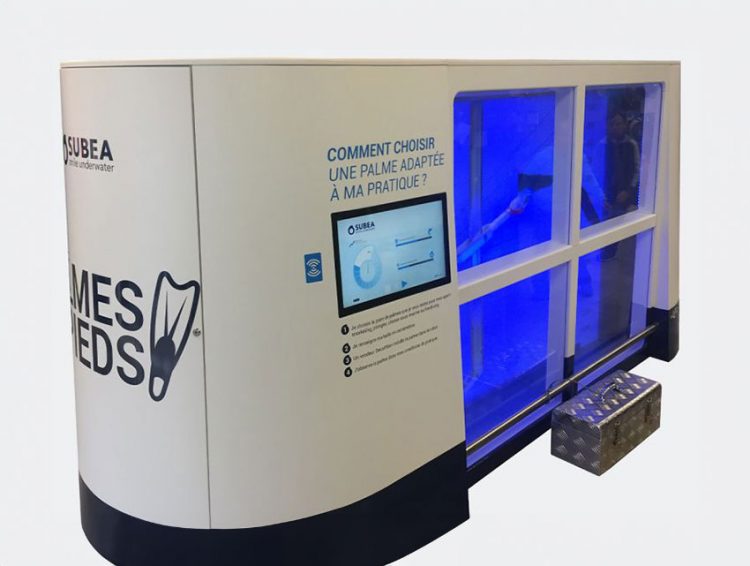

The test bench can be used to demonstrate product quality to customers, or to train future users. This is a demonstration bench.

This process has already been used by Décathlon, who use test benches to demonstrate the performance of their fins.

Watch the video of this bench here :https://youtu.be/E7CiaLkwmvw

Certification bodies and their use of test benches

They use test benches to verify the operation and service life of products put on the market according to the tests described in the standards and quality marks.

Thanks to these tests, these organizations are authorized to certify manufacturers’ products.

Finally, they use it to support manufacturers’ quality and R&D departments in new product development and quality management.

Do you have a project ? Contact our test bench experts

Discover other articles and tips

What methods are used to test pipes in the building industry?

What are the most important tests on sanitary hoses ?

What are the main types of water heaters ?