Automatic Cartridge adjustment bench

Cartridge adjustment bench sets the temperature control position and tests cartridge performance

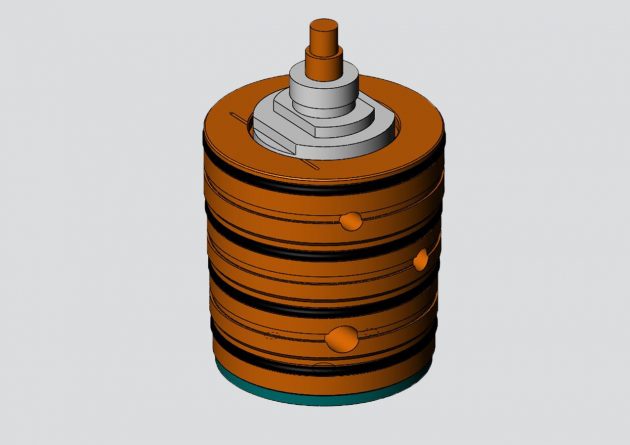

Products tested

Sector of activity

Main functions

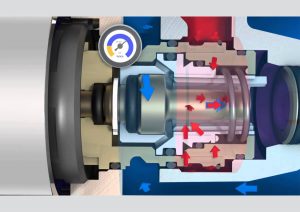

The thermostatic cartridges adjustment and test bench allows to test the behavior of a thermostatic cartridge (sealing, flow, antiscald) and to adjust the temperature control of the cartridge manually or automatically.

The manual thermostatic cartridges adjustment and control bench allows :

- an air and/or water sealing test

- the setting of mixed water temperature and flow rate

- the measurement of the mixed water temperature in full hot position

- the sealing measurement

- measurement of antiscald and hysteresis

Operating mode

Find out how our automatic temperature control and test bench for thermostatic cartridges works.

- Installation of the cartridge

- Air and water sealing test

- Mixed temperature setting

- Flow measurement

- Antiscald (safety test) and hysteresis measurement

- Marking of the set position (optional)

- Emptying and blowing the cartridge

Characteristics of the device

- 1 stainless steel frame

- Hydraulic assembly consisting of :

- 2 pumps (HW and CW)

- 3 pressure sensors

- 1 mass flowmeter

- 5 temperature sensors (HW and CW)

- 1 electrical cabinet

- 1 PC and 1 touch screen

Benefits

- Speed and repeatability of tests and adjustments

- Automatic clamping and unclamping of the cartridges in complete safety

- Archiving of all production controls

- Traceability

Bench developed to meet these standards:

EN-1112

Temperature and flow control

The pumps bring the water to the desired pressure and the machine automatically adjusts the mixed temperature.

Numerous tests carried out

Leak test, flow rate, antiscald and hysteresis, mixed temperature in hot conditions, pressure variation, etc.

Marking system

Automatic milling marking system

Endurance Automatic Temperature Control and Test Bench for Thermostatic Cartridges

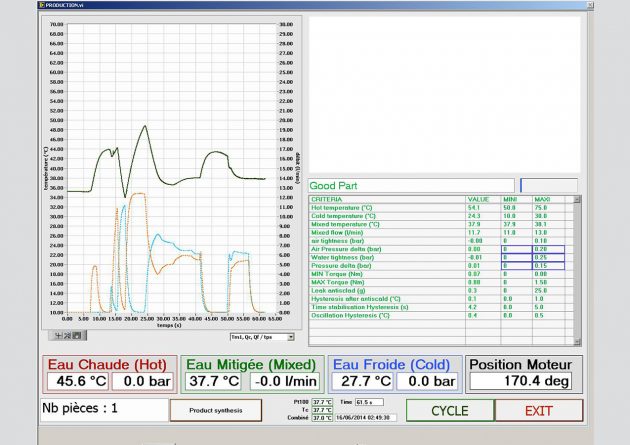

Production bench used to adjust and control thermostatic cartridges. This bench allows to : – Check the presence of seals by a leak test. – Control the hot and cold water pressures. – Check that the water supply temperatures are within the range defined by the user. – Check the flow rate setting. – Carry out a mixed temperature test in the full hot position (C3 / ECAU standard). – Operate the cartridge over its full operating range and check the operating torque. – Automatically set the mixed water temperature to 38°C. – Perform antiscald and hyteresis test. – Carry out a milling of the cartridge to locate the 38°C – Dry the cartridges by blowing air.

Advantages of ThermControl-Auto

Reproductibility test

Fast and repeatable testing and adjustment

Automatic cartridge clamping

Automatically and safely clamps and unclamps cartridges.

Automatic reports

Archiving of all production checks with automatic test reports.

Tool detection

Automatic detection of the tooling according to the cartridge and the chosen test.

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test