Endurance bench for mechanical cartridges

Endurance test bench for mechanical cartridges for mixing valves

Products tested

Sector of activity

Main functions

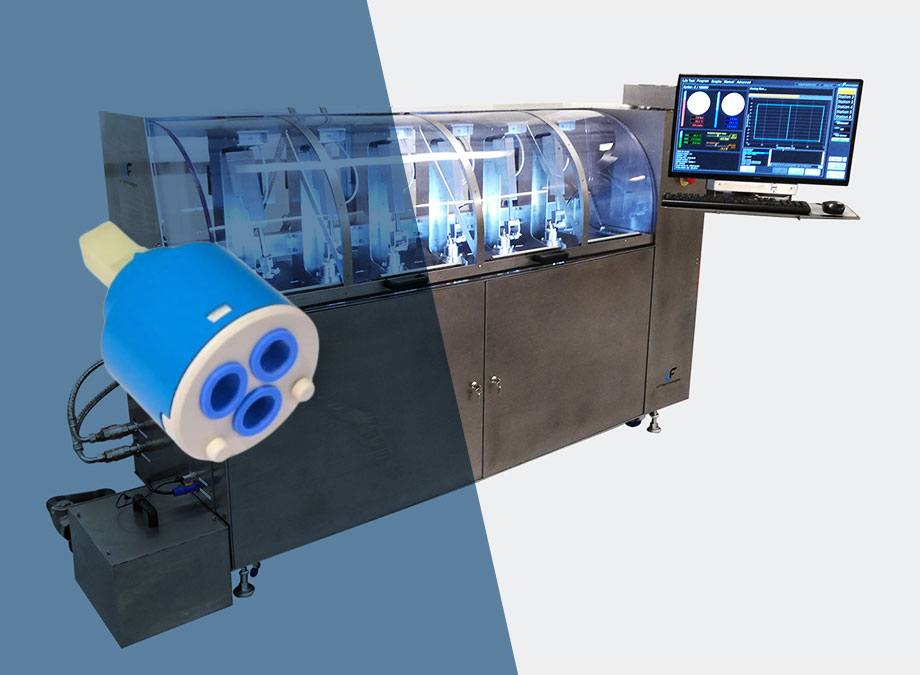

LifeCartM is an endurance test bench for verifying the service life, performance and hydraulic characteristics of mechanical cartridges for mixing valves.

Tests are carried out to comply with standards such as EN 817 and NF 077.

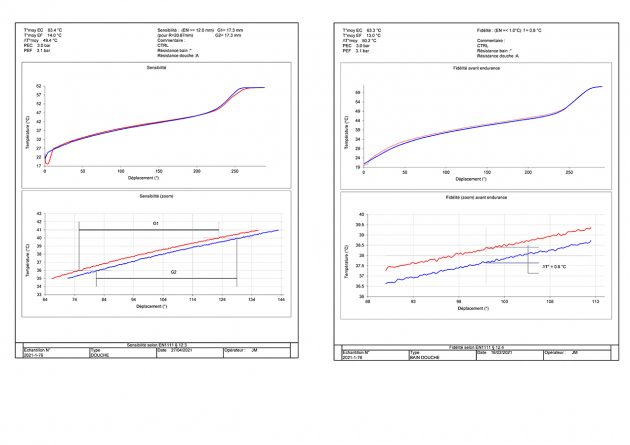

- Fidelity measurement, sensitivity, flow determination, etc.

- Tightness and static pressure tests at 16 or 25 bar

- Temperature control with torque measurement

- Flow control with force measurement

- Measurement and monitoring of supply temperature and pressure

- Endurance cycles

- Automatic report editing

Operating mode

Discover how our endurance test bench for mechanical cartridges works

The equipment is a test bench equipped with several modules (from 2 to 6), designed to carry out performance and endurance tests on mechanical cartridges for mixing valves.

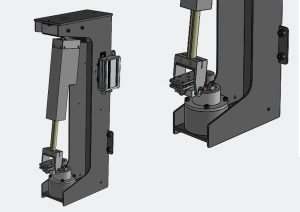

Each cartridge tested is mounted in a special tool, connected to a hot and cold water supply and a piped mixed water outlet. The cartridge control lever is operated automatically by 2 actuators (1 rotary and 1 linear), capable of performing movements with position, speed and torque/force control. What’s more, each module is equipped with a static pressure generator for leak testing and mechanical resistance to pressure of up to 16 bar or 25 bar.

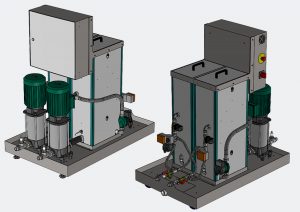

The bench is connected to 2 hot and cold water inlets. Temperature is generated outside the bench. Hot and cold water supply pressures are provided either directly by the network supplying the bench, or by an external pressure generator (optional).

The software performs all performance and endurance tests by simple programming.

Benefits

- Independent or synchronized testing

- Standard-compliant testing

- Flexibility

Bench developed to meet these standards:

Independent test bench stations for mechanical mixer cartridges

Independent test bench stations for mechanical mixer cartridges

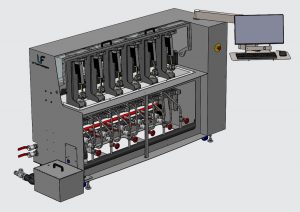

CAD – Endurance bench for mechanical cartridges

CAD - Endurance bench for mechanical cartridges

Independence of test stations

Independence of test stations

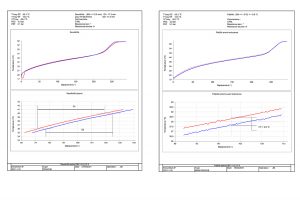

Automatic test reports

Automatic test reports

Endurance bench test station for mechanical cartridges

Endurance bench test station for mechanical cartridges

Benefits of LifeCartM

Independence of test stations

Automatic test reports

Automatic test reports based on selected standards.

TECHNICAL SPECIFICATIONS of the Endurance Bench for Mechanical Cartridges

Specifications | LifeCartM2 | LifeCartM4 | LifeCartM6 |

Hydraulic performance | |||

Hot and cold flow / test module | 0-10 l/min | 0-10 l/min | 0-10 l/min |

Pressure measurement | +/- 0,05 bar | +/- 0,05 bar | +/- 0,05 bar |

Mixed water flow measurements | +/- 0,2 l/min | +/- 0,2 l/min | +/- 0,2 l/min |

Maximum static test pressure | 16 bar or optional 25 bar | 16 bar or optional 25 bar | 16 bar or optional 25 bar |

With Pressure Generation option | |||

Hot and cold supply pressure | 0-10 bar | 0-10 bar | 0-10 bar |

Hot and cold dynamic pressure regulation | 0,1-8 bar | 0,1-8 bar | 0,1-8 bar |

Hot and cold static pressure regulation (with pumps) | 0,1- 10 bar | 0,1- 10 bar | 0,1- 10 bar |

Precise pressure regulation with pumps | <0,1 bar | <0,1 bar | <0,1 bar |

Thermal performance | |||

Permissible water supply temperature range | 10-85°C | 10-85°C | 10-85°C |

Measurement of hot, cold and mixed water temperatures | +/- 0,5°C | +/- 0,5°C | +/- 0,5°C |

Station dimensions | |||

Width | 1 760 mm | 2 080 mm | 2 400 mm |

Depth | 1 300 mm | 1 300 mm | 1 300 mm |

Height | 1 400 mm | 1 400 mm | 1 400 mm |

Weight | 200 kg | 250 kg | 300 kg |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test