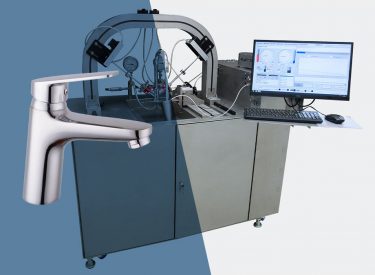

Endurance test bench for sanitary tapware

- Quick and easy installation of faucets of any form

- Automatic tests without manual intervention

- Automatic termination in case of leakage or abnormal operating torque

- Reproducibility of tests

Products tested

Sector of activity

Main functions

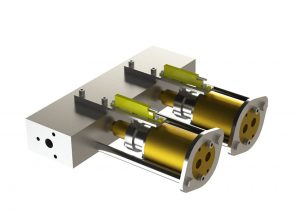

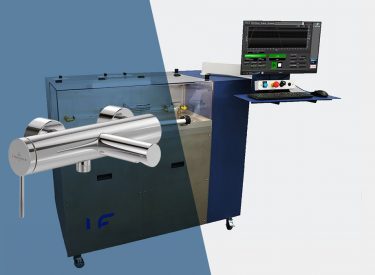

The endurance test bench is a test bench designed to test the lifetime of faucets, mixers, diverters, mechanical and thermostatic mixers in a fully automated way and according to NF, EN, ASSE standards, etc.

The machine is equipped with an automated measurement system evaluating the reliability of the valve during its endurance according to the evolution of the operating torque and its sealing.

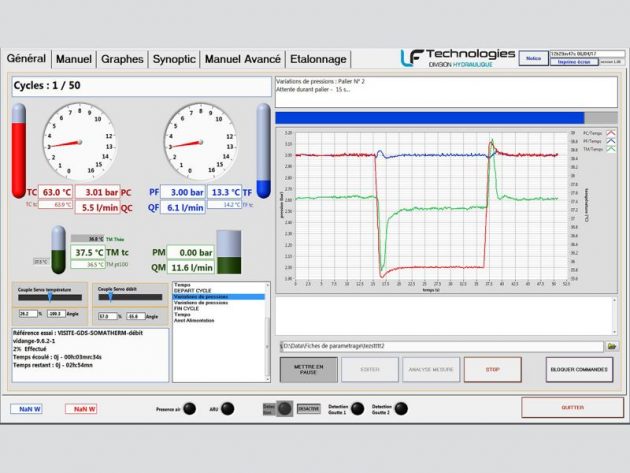

Operating mode

Discover how our endurance test bench for valves works

- Fixation of the faucet to be tested on the central stage;

- Adjustment of the faucet position;

- Mounting of actuators for motion control (rotation or translation);

- Programming of tests on the control screen;

- Launch of scenarios.

Characteristics of the device

- Stainless steel frame

- PC control

- Pressure control 0.1 to 6 bar ± 0.05 bar

- Flow rate 2×25 l/min

- Automatic leak detection

- Operation force/torque 100 N; 6 Nm

- Closed enclosure for protection against water splashes

Bench developed to meet these standards:

Thermostatic mixing valves EN1111

Thermostatic mixing valves EN1111

Single-lever mechanical mixing valve – EN817

Single-lever mechanical mixing valve - EN817

Timer valve EN816

Timer valve EN816

Endurance test in accordance with EN816

Endurance test in accordance with EN816

Enceinte fermée

Closed enclosure providing protection against potential water splashes.

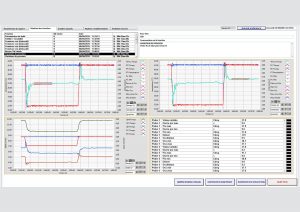

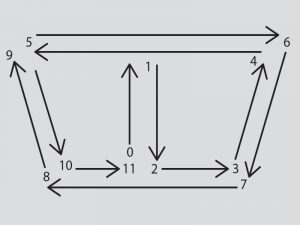

Standard endurance cycle for mechanical mixers

Standard endurance cycle for mechanical mixers

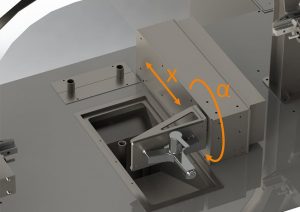

Endurance Joystick mixer

Automated movement of a joystick-controlled mechanical mixing valve using 2 actuators. A rotary actuator for temperature control and a linear actuator for flow control.

Advantages of LifeMulti

Simple assembly

Quick and easy installation of valves of any shape

Leak detection

Automatic shutdown in case of leakage or abnormal operating torque.

PC control

Simple test initiation and monitoring via PC control.

TECHNICAL CHARACTERISTICS of the Endurance Test Bench for Valves and Fittings

Specifications | LifeMulti |

Hydraulic performance | |

EC and EF flow | 0-25 l/min |

EC and EF pressure | 0-6 bar |

Pressure measurement | ± 0,01 bar |

Flowmetering EC, EF, EM | ± 0,1 l/min |

Thermal performance | |

Temperature range (depending on source) | 5-75° C |

EC, EF, EM temperature measurement | ± 0,2° C |

Mechanical performance | |

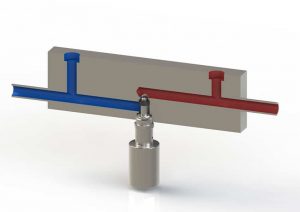

Rotary actuator | |

Max. torque in both directions | 6 N.m |

Max. speed in 2 directions | 180°/s |

Torque measurement resolution | 0,01 N.m |

Resolution of angular position measurement | 0,1° |

Max. angle of rotation | illimité |

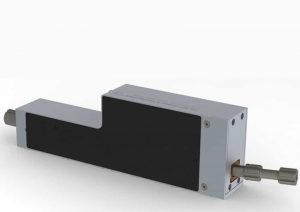

Linear actuator | |

Max. force in 2 directions | 100 N |

Max. stroke | 125 mm |

Max. speed | <40 mm/s |

Force measurement accuracy | ± 0,1 N |

Position measurement accuracy | ± 0,02 mm |

Dimensions of a workstation | |

Width | 550 mm |

Depth | 650 mm |

Height | 2 100 mm |

Weight | ≈170 kg |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test