Hot water and cold water generator

The hot & cold water generator is designed for hydraulic test benches, offering performance suitable for a variety of industrial applications. It is available in three thermal power configurations: 15 kW, 25 kW and 35 kW, for heating and cooling. With a continuous mixed water flow rate of 14 to 34 liters per minute, depending on the power selected, it ensures precise regulation with a tolerance of ±0.3°C. The system is equipped with a 600-liter hot water tank 600-liter hot water, and a 400-liter chilled water reserve tank. It also includes an anti-legionella system, automatic filling and automatic balancing.

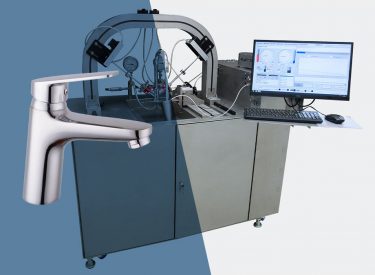

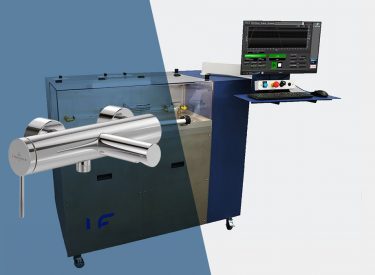

Products tested

Sector of activity

Characteristics of hot and cold water generators

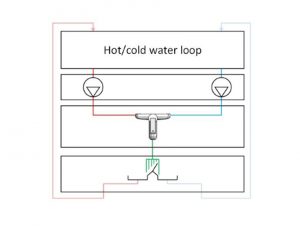

The hot and cold water generator regulates the temperature of a hot water tank and a cold water tank to supply hot and cold water to tap test benches, all in a closed circuit.

Equipped with a heating and cooling system, this generator can supply, continuously and in a closed circuit, a total mixed flow of 14, 24 or 34 l/min with a deltaT of 50°C.

Thanks to its energy recovery system, this generator provides a total thermal output (heating + cooling) approximately 2 times the electrical power consumed.

Coupled with benches equipped with hot and cold water distributors, energy consumption can be greatly reduced when the taps tested are not in the mixing position (50% hot 50% cold).

Operating mode

Discover how our hot and cold water generator works

A tank of chilled water, used as a cold reserve, is cooled by a heat pump. This heat pump transfers some of the calories “pumped” from the cold store to the hot water tank.

The chilled water tank is controlled by a servo-controlled exchange with the chilled water tank.

The hot water tank is regulated by an electric resistance.

The surplus heat (the part not recovered by the heat pump) is evacuated by a unit heater, which can be remote from the generator.

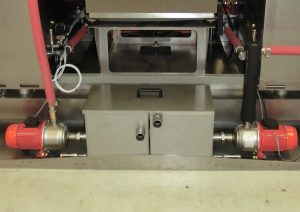

All fluids are circulated by speed-controlled centrifugal pumps.

The tanks are made of double-skinned stainless steel with polyurethane insulation.

Each tank is equipped with several temperature sensors to measure any temperature stratification (water colder at the bottom, warmer at the top) and, in this case, trigger automatic mixing.

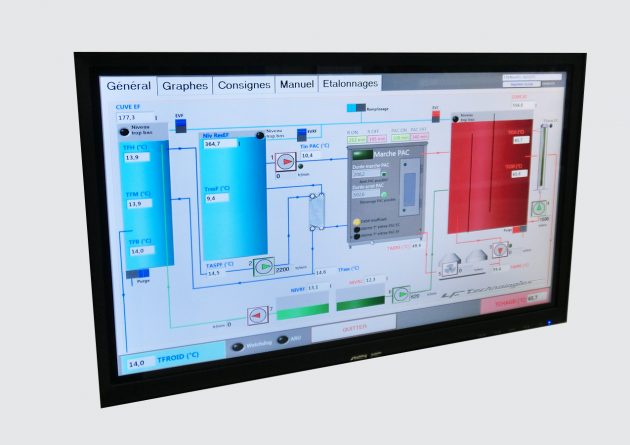

The whole system is controlled by a PC equipped with a program ensuring temperature regulation to ± 0.3°C whatever the flow rate, while managing tank level safety devices, automatic tank balancing, etc.

Générateur d’eau chaude et d’eau froide

The generator regulates the temperature of a hot water tank and a cold water tank; These tanks operate in a closed circuit, reducing water consumption;

Banc d’endurance + banc de performance

The hot/cold water generator can simultaneously supply two endurance stations and one performance station, or two production stations (38°C setting at 12 l/min).

Pompes centrifuges

All fluids are circulated by speed-controlled centrifugal pumps.

Cuve de régulation isolée

The tanks are made of double-skinned stainless steel with polyurethane insulation.

Générateur-eau-chaude-eau-froide

Boucle Primaire d’eau – Générateur 20 kW

Advantages of the WaterBank – Hot and Cold Water Generator

Energy saving

Energy recovery using a heat pump.

PC control system

The PC is equipped with a program for temperature control to +/- 0.2°C, regardless of flow rate.

TECHNICAL SPECIFICATIONS of the Hot & Cold Water Generator

Specifications | WaterBank-15 | WaterBank-25 | WaterBank-35 |

Hydraulic performance | |||

Heating capacity | 15 kW | 25 kW | 35 kW |

Cooling capacity | 15 kW | 25 kW | 35 kW |

Continuous mixed water flow with Delta T° 50° C | 14 l/min. | 24 l/min. | 34 l/min. |

Power consumption (at Delta T° 50° C, Qmitigated above according to range) | 20 kW | 30 kW | 35 kW |

Min. temperature EF | 10° C | 10° C | 10° C |

Max. temperature EC | 75° C | 75° C | 75° C |

Control accuracy | ± 0,3° C | ± 0,3° C | ± 0,3° C |

Anti-legionella system | |||

Automatic filling | |||

Automatic balancing | |||

EC-EF production system consisting of : | |||

1 cuve EC | 600 l. | 600 l. | 600 l. |

1 cuve EF | 200 l. | 200 l. | 200 l. |

1 chilled water reserve tank | 400 l. | 400 l. | 400 l. |

1 heat pump | |||

1 unit heater | |||

Dimensions of an EC-EF generator | |||

Length | ≈ 3 000 mm | ≈ 3 000 mm | ≈ 3 000 mm |

Width | ≈ 2 000 mm | ≈ 2 000 mm | ≈ 2 000 mm |

Height | ≈ 1 600 mm | ≈ 1 600 mm | ≈ 1 600 mm |

Weight | ≈ 1 400 kg | ≈ 1 400 kg | ≈ 1 400 kg |

Customer applications

Would you like to find out more about hydraulic test benches? Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test