What is a Hydraulic Proof Test ?

A hydraulic proof test is a strength test where a component, such as a pipe, tank, or vessel, is subjected to a pressure higher than its normal operating pressure (service pressure) for a certain period At the end of this test, the component must not show any deterioration. This process is crucial for identifying structural weaknesses and ensuring compliance with safety standards.

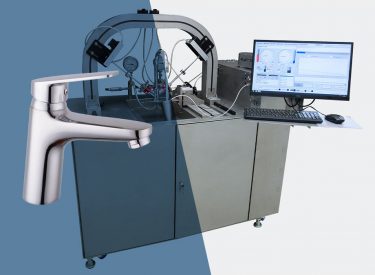

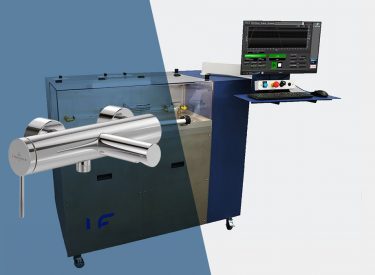

LF Technologies: A Complete Range of Hydraulic Testing Benches

LF Technologies offers a range of equipment for a variety of proof pressure controls, simple or repetitive tests, on small or large volumes, with or without fluid circulation, with or without leak detection. In particular, they can be used to generate simple or cyclic tests, with or without fluid circulation, with or without leak detection;

OUR KEY TEST BENCH FOR HYDRAULIC PROOF TESTING – WPC

- Suitable for Large Volume Items: It is specially designed to test large-sized objects, ensuring their reliability under pressure.

- Tests with Hot Water: This feature allows for assessments under high temperature conditions, simulating real-use scenarios.

- Easy Implementation: The system is designed for intuitive use, making evaluation procedures less complex.

Test Data Archiving: It offers the capability to store test reports and result data, facilitating tracking and analysis. - Custom Test Programming: Allows for programming various test profiles, including straight or sinusoidal ramps and dwell time and plateaus, with the option for cyclic repetition of procedures.

The WPC is particularly well-suited for testing the high-capacity of sanitary equipment, with several maximum pressure versions (16, 20, 25 bars). It offers a simple, complete, and efficient solution for evaluating the robustness of hydraulic systems and the resilience of tanks under challenging conditions.

Bench developed to meet these standards:

EN-12897

Our hydraulic test benches

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Customer applications

Discover LF Technologies know-how through our customer applications.

HYDRAULIC PROOF TESTING BENCHES: A PLEDGE OF SAFETY

Hydraulic proof testing involves subjecting components such as hot water tanks, pipes, or faucets to pressures exceeding their service pressure. Their goal is to confirm the components’ endurance under extreme conditions. These procedures are fundamental for ensuring the safety of users and installations, and for meeting industry standards

Conducting a Hydraulic Proof Test

Key Process Steps

- Preparation and Safety: First and foremost, it is essential to verify the integrity of the object to be tested and to ensure that the test environment is secure.

- Pressurization: The object is then gradually pressurized using a fluid, typically water or oil.

- Monitoring and Inspection: Throughout the test, rigorous monitoring is conducted to detect any leaks, deformations, or failures.

- Pressure Release: After the test, the pressure is slowly decreased, and the object is inspected to evaluate the results.

The Hydraulic Testing Bench by LF Technologies: Technology and Expertise

LF Technologies performs hydraulic checks to confirm the robustness and reliability of industrial equipment under high pressure. These procedures, vital for the safety of systems such as pipelines and tanks, are conducted according to European standards to ensure precise and secure examinations, thereby enhancing the equipment’s robustness under difficult conditions.

They trust us

Advice from our experts

Would you like to find out more about hydraulic test benches? Find out everything you need to know and much more!