Single lever mixers/thermostatic cartridges – Temperature adjustment and test

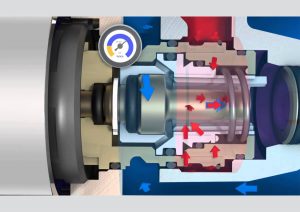

The thermostatic mixing valve/cartridge adjustment and test bench carries out the testing and adjustment, in production, of thermostatic mixing valves/cartridges (tightness, flow rate, anti-scalding).

Products tested

Sector of activity

Main functions

The thermostatic mixing valve/cartridge adjustment and test bench carries out the testing and adjustment, in production, of thermostatic mixing valves/cartridges (tightness, flow rate, anti-scalding).

The manual adjustment and control bench for thermostatic mixing valves/cartridges allows :

- air and/or water tightness test

- adjustment of the temperature and flow rate of the mixed water

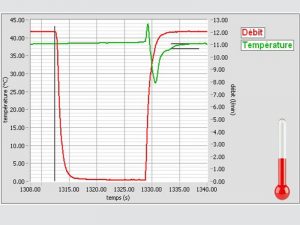

- measurement of the mixed water temperature in hot conditions

- measurement of flow rate

- antiscald and hysteresis measurement

Operating mode

Find out how our temperature control and test bench for thermostatic mixing valves and cartridges works.

Programmable test cycle :

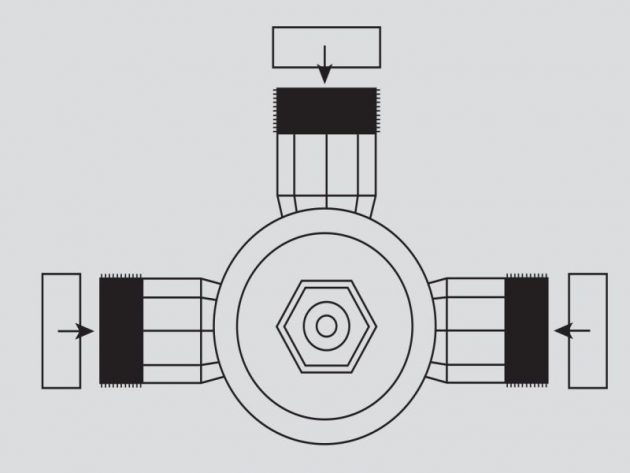

- Installation of the mixer/cartridge with clamping without screwing

- Air and water tightness test

- Mixed temperature setting

- Flow rate measurement

- Anti-scalding test (safety test) and hysteresis measurement

- Marking of the set position (optional)

- Draining and blowing out the mixer

Control :

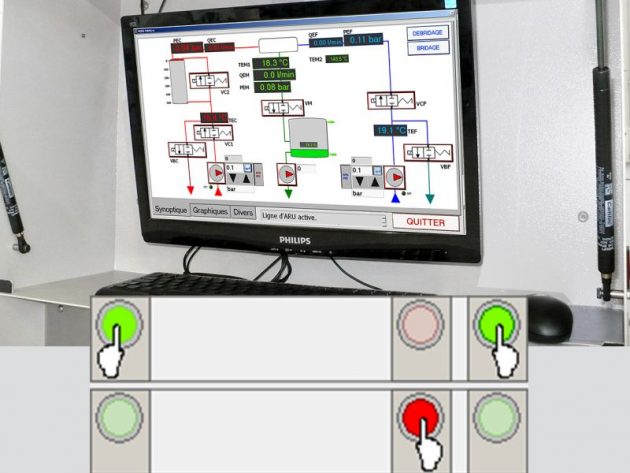

The system is computer controlled. The software allows :

- editing and selection of test programs

- the visualization of the measurements

- edition of an automatic control report on the production batch.

In production mode, the operator controls the bench directly with the buttons on the front panel of the test bench.

Test boards:

The mixers or cartridges are fixed on a test board. The bench can be fitted with several different plates, each adapted to a different shape of tap. The plates are equipped with a quick connection system which allows the plate to be changed in a few seconds.

Device features

- Stainless steel frame

- Hydraulic assembly consisting of :

- 2 pumps (EC and EF)

- 3 pressure sensors (EC, EF and EM)

- 2 flowmeters (EC and EF)

- 3 temperature sensors (EC, EF and EM)

- Control cabinet

- PC + touch screen

Bench developed to meet these standards:

EN-1111

Control panel for thermostatic valves

Check the safety temperature limit on thermostatic valves.

Removable control plate for testing thermostatic mixing valves

Quick and easy interchangeability of different test boards.

Cartridge temperature setting bench

Cartridge temperature setting bench

Adjustment plate for thermostatic cartridges

Adjustment plate for thermostatic cartridges

Thermostatic cartridge test zone

Thermostatic cartridge test zone

THERMCONTROL-MANU – Cartridge Test Zone

Cartridge temperature setting bench

Benefits of ThermControl-Manu

Reproducibility

The use of control software enables rapid, repeatable automatic testing.

Bridle / unbridle

Automatic cartridge clamping and unclamping in complete safety.

Ergonomics

Parameters are set on a touchscreen, and operations are controlled by 3 buttons on the front panel.

TECHNICAL SPECIFICATIONS of the temperature control and test bench for mixing valves/thermostatic cartridges

Specifications | ThermControl-Manu-Valve | ThermControl-Manu-Cart |

Max. test pressure | 5 bar | 5 bar |

Pressure regulation accuracy (at constant flow rate) | ± 0,02 bar | ± 0,02 bar |

Max. hot/cold water flow | 2 x 25 l/min | 2 x 25 l/min |

Temperature measurement accuracy | ± 0,3° C | ± 0,3° C |

Flow measurement accuracy | ± 0,2 l/min | ± 0,2 l/min |

Pressure measurement accuracy | ± 0,02 bar | ± 0,02 bar |

Accuracy of standard antiscald volume measurement | 25g /5s | 25g /5s |

Accuracy of antiscald volume measurement (accuracy option) | 3g /5s | 3g /5s |

Multi-station board | NO | YES |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test