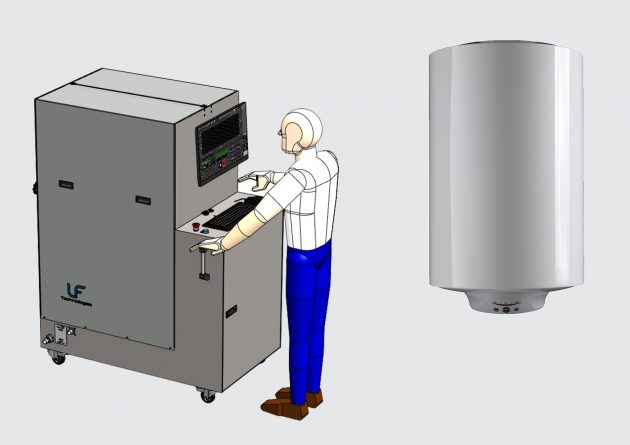

Mobile pressure generator

Pressure generator for test pressure and alternating pressure tests on pressure vessels

Products tested

Sector of activity

Main functions

The WPC is a pressure generator for performing proof pressure and alternating pressure tests on large capacity water heater pressure vessels EN 12897.

These tests can be performed under water circulation, with temperature control.

The products tested with this bench :

- pressure vessels (e.g. water heaters)

- pumps and pump bodies

- pipes

- valves and valve bodies

Operating mode

Find out how our mobile pressure generator works

The products to be tested are connected to the generator via hoses, which are placed next to the test bench. The generator is connected to a water supply (city water) and to the drain.

Once the products are connected, the generator manages :

- the filling of the products

- the generation of the test pressure according to a programmable profile

- water circulation

- maintaining the temperature of the test water thanks to an integrated heater.

The pressure generator is compact and mounted on wheels, which allows it to be easily moved close to the product to be tested.

The generator is controlled by a PC equipped with test software that allows easy generation of test programs, storage of these programs, real-time display of measurements, saving of results files and editing of reports.

Benefits

- Compact and mobile solution

- Possibility to test large volume products

- Possibility of testing with hot water

- Easy to implement tests

- Ability to save test sheets and results files

- Possibility to program straight or sinusoidal ramps and steps, with cycling

Bench developed to meet these standards:

EN-12897

WPC benefits

Compact, mobile unit

The pressure generator is compact and mounted on wheels, which allows it to be easily moved close to the product to be tested.

TECHNICAL SPECIFICATIONS of the Mobile Pressure Generator

Specifications | WPC16 | WPC20 | WPC25 |

Hydraulic / thermal performance | |||

Maximum static pressure | 16 bars | 20 bars | 25 bars |

Minimum test pressure | 0,5 bars | 0,5 bars | 0,5 bars |

Pressure measurement accuracy | 0,1 bars | 0,1 bars | 0,1 bars |

Control accuracy (in steps) | 0,2 bars | 0,2 bars | 0,3 bars |

Maximum pressure build-up ramp (Within the limit of the maximum flow rate) | 1 bars/s | 1 bars/s | 1 bars/s |

Maximum flow rate (manual adjustment via proportional valve) | 50 l/min | 50 l/min | 50 l/min |

Maximum test fluid temperature (°C) | 95 | 95 | 95 |

Maximum variation in volume during the test | 50 l | 50 l | 50 l |

Dimensions | |||

Length | 1 260 mm | 1 260 mm | 1 260 mm |

Width | 850 mm | 850 mm | 850 mm |

Height | 1 610 mm | 1 610 mm | 1960 mm |

Tare weight | 350 kg | 350 kg | 400 kg |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test