Understanding Pressure cycle Testing

Cyclic pressure testing simulates the repeated variations in pressure experienced by a component throughout its life cycle. This test is crucial for :

- Identify structural weaknesses,

- Guaranteeing the durability of equipment,

- Prevent premature breakdowns.

By accurately reproducing these constraints, manufacturers obtain reliable data to optimise the quality and safety of their products.

Why choose LF Technologies for your cyclic pressure tests?

LF Technologies puts its expertise at the service of industry to guarantee accurate, reliable cyclic pressure tests that comply with the most stringent requirements. Our know-how is based on advanced technical solutions, such as the use of a highly dynamic motorised syringe, enabling extremely rapid pressure rises and falls, in just 0.2 seconds.

This unique technology enables us to reproduce the real stresses experienced by your components, ensuring rigorously controlled and reproducible tests. By choosing LF Technologies, you benefit from total control of the test process, optimisation of your equipment and guaranteed compliance with international standards. Each test bench we design is designed to combine performance, safety and durability, providing manufacturers with reliable data to improve the quality and robustness of their products.

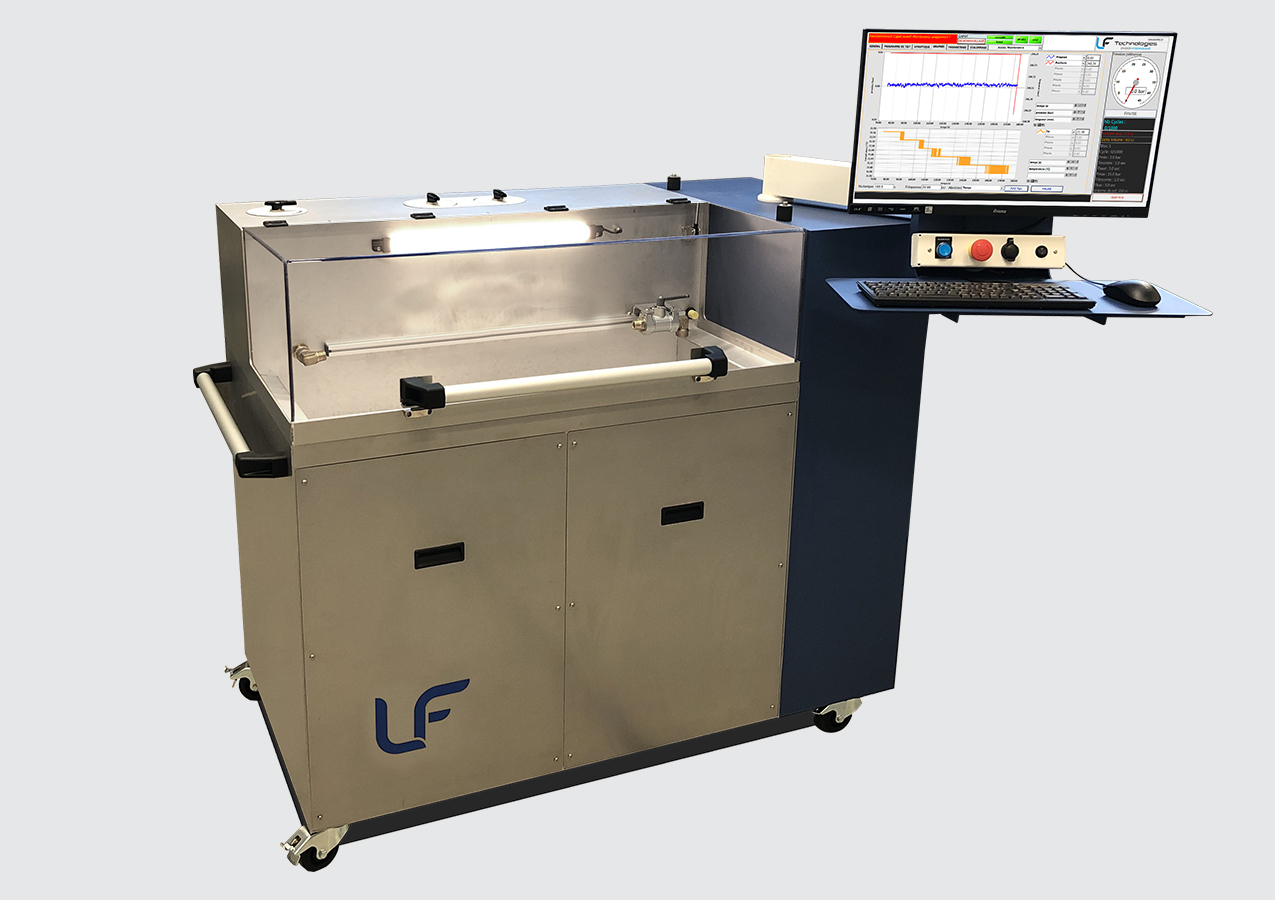

Our key test bench for Cyclic Pressure Testing – HYDROSHOCK

The HYDROSHOCK bench from LF Technologies is specially designed to test the tightness and resistance of hydraulic components to alternating pressure cycles. Thanks to its advanced technology, it accurately simulates the pressure variations experienced in real-life conditions, reproducing in particular the effects of water hammer, common in plumbing and industrial systems.

Equipped with a high-performance motorised syringe, the HYDROSHOCK can achieve rapid pressure rises and falls of up to 0.2 seconds, guaranteeing tests that comply with the most demanding standards. This test rig is ideal for pushing equipment to its limits, assessing its robustness in the face of repeated and extreme stress.

- Standard tests according to standards

- Programmable pressure cycles

- Quick and easy installation of valves and fittings of any shape

- Automatic shut-off in the event of leakage from the product under test

- Test reproducibility

- Automatic analysis and test reports

- Compact package

- Maximum static pressure from 50 to 200 bar

Bench developed to meet these standards:

NF077-doc tech 3

Our test benches for these cyclic pressure test

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Cyclic pressure test applications

Cyclic pressure testing has essential applications in various industrial sectors where the robustness and reliability of equipment are paramount. Thanks to our high-performance test benches, such as the HYDROSHOCK, LF Technologies helps professionals to validate their components and systems.

In thevalves and fittings industry, these tests check the resistance of hoses, valves and mixing valves to repeated pressure cycles. In the automotive sector, they ensure the durability of hydraulic systems by simulating extreme conditions of use. Finally, in the buildingand plumbing sectors, they reproduce the effects of pressure variations to prevent the risks associated with water hammer, thereby guaranteeing the safety and performance of installations.

Whatever the sector, our test benches provide accurate, reproducible results to help manufacturers anticipate failures, improve the quality of their products and comply with the most stringent standards.

Customer applications

Discover LF Technologies know-how through our customer applications.

They trust us

Principles and operation of cyclic pressure testing

Cyclic pressure testing involves applying repeated cycles of pressure rise and fall to a component or system to assess its resistance and detect any faults. This process faithfully reproduces the stresses experienced under real conditions of use, making it possible to anticipate weak points and ensure the robustness of the products tested.

At LF Technologies, our test benches are designed to perform these cycles with great precision thanks to our motorised syringe technology. This innovation makes it possible to achieve extremely rapid and controlled pressure variations, offering reliable and reproducible results.

Operation is based on a succession of alternating pressures, programmable as required, to simulate phenomena such as water hammer. These tests make it possible to :

- Detect leaks and structural weaknesses,

- Assess the durability and performance of components,

- Guarantee compliance with the most demanding industrial standards.

Thanks to this rigorous methodology, our test benches play a key role in the continuous improvement of products, by providing data that can be used to optimise the quality and safety of equipment.

Advice from our experts

Would you like to find out more about hydraulic test benches? Find out everything you need to know and much more!