Cyclic Pressure and Temperature Test Bench

This bench is used to test the pressure and temperature resistance of sanitary appliances

Products tested

Sector of activity

Main functions

The test loop enables testing the resistance to pressure and temperature of pumps, circulators, valves or sanitary appliances in continuous operation. The software allows to monitor in a controlled manner the progressive degradation of the tested sample.

The test bench is primarily intended for research and development laboratories wishing to optimize product design.

Operating mode

Discover how our Cyclic Pressure and Temperature Test Bench works

Once installed, the device is supplied with water and undergoes cycles of pressure and temperature variations. Thanks to low volumes of hot and cold water, the test bench offers a very energy-efficient operation compared to conventional solutions on the market.

Benefits

- Large energy savings thanks to the optimization of the exchange of hot and cold water during the temperature shocks

- Ability to test multiple devices simultaneously and independently

Hoses

A special built-in circulator makes it possible to carry out ageing tests on hoses.

Energy saving

Great energy savings thanks to optimised hot and cold water volumes during temperature shocks.

Boiler bottoms

Service life test for domestic hot water boilers.

TCPUMP – Cyclic Pressure and Temperature Test Bench – LF-Technologies

TCPUMP - Cyclic Pressure and Temperature Test Bench - LF-Technologies

TCPUMP-Hydraulic test bench

TCPUMP - Cyclic Pressure and Temperature Test Bench - LF-Technologies

TCPUMP – Cyclic Pressure and Temperature Test Bench – LF-Technologies

TCPUMP - Cyclic Pressure and Temperature Test Bench - LF-Technologies

TCPump benefits

Energy saving

High energy savings due to optimised hot and cold water volumes during temperature shocks.

Independence test stations

Different tests are performed simultaneously on several independent components and stations.

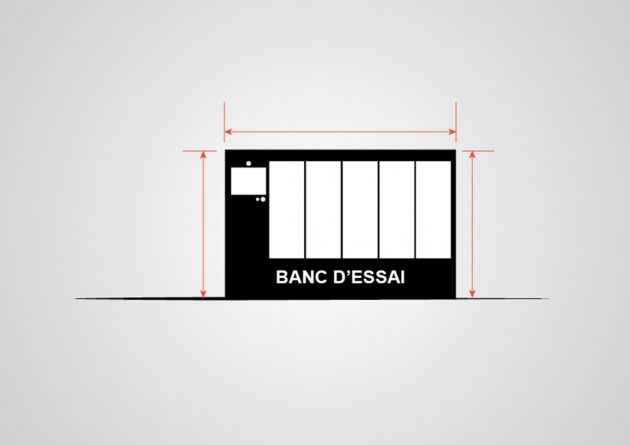

Small footprint

Space-saving thanks to the dimensions of 3×1 m and a height of 2.20 m (for 5 independent stations).

Simple assembly

The products to be tested are easy to mount on the bench and require minimal operator movement.

TECHNICAL SPECIFICATIONS of the Cyclic Pressure and Temperature Test Bench

Specifications | TCPump |

Performance | |

Test pressure | from 0.5 to 30 bar |

Temperature EF | from 15 to 35°C |

EC temperature | from 35 to 105°C |

Power supply (three-phase + neutral + earth) | 400 V - 32 A |

Max. test condition for 2000 W cooling unit (Eurodifroid - Ref. : RFC 20 230V-1-50 Hz) | 4 stations in 20-minute cycle between 25 and 95°C |

Pressure intensifier stroke | 350 mm |

Ø multiplier plunger piston | Ø 16 |

Acquisition (for recording files) | 50 ms |

Pressure control accuracy (according to trapezoid, sine, etc.) | ± 0,1 bar |

Temperature control accuracy (stabilised phase) | ± 2°C |

Dimensions | |

Length | ≈ 3 000 mm |

Width | ≈ 1 000 mm |

Height | ≈ 2 200 mm |

Weight | ≈ 1 200 kg |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test