Tube bursting bench

This bench is designed to carry out test pressure and/or burst tests on flexible or rigid pipes; It is capable of testing:

- Long corrugated tubes (which deform considerably when pressurised)

- Short rigid tubes (with very high resistance to pressure)

- Large expansion volume

- Adjustable pressure ramps and bearings;

- Tools for quick connection of pipes

Products tested

Sector of activity

Main functions

This bench is equipped with a static pressure generator, specially developed for high expansion tube testing.

The pressure generator makes it possible to apply a progressive pressure build-up, as well as pressure levels, with controlled pressure (even in the event of creep under pressure of the product tested).

This very gradual and regular rise in pressure allows detect very precisely the maximum burst pressure or hernia formation on the tube under test.

The pressure generator is a motorized syringe. The precision control of this motor allows for fine measurement and regulation of pressure, with a user-configurable pressure rise rate, as well as automatic detection of the rupture point. This technique also ensures intrinsic safety for the user during a burst (as there is virtually no energy storage in the system).

The internal volume of the syringe is sized to cover a wide range of expansion volumes of the tested products. And in case of a greater volume, the machine is equipped with an automatic valve, allowing the pressure in the tube to be maintained while the syringe refills.

The tooling for connecting plastic tubes easily adapts to various diameters and lengths of tubes, without constraining the ends.

Operating mode

The tube under test is connected to quick-connect tooling; These tools are mounted on mobile trolleys to adapt to the length of the tube;

The system applies static pressure according to a programmable cycle, with gradual pressure build-up ramps and adjustable stages;

The test zone is fitted with a transparent cover featuring a safety switch that automatically cuts off the pressure when the cover is opened;

Features

The test bench consists of 6 parts:

- The self-supporting stainless steel chassis on castors

- The test area, including the connections for the products to be tested and a recovery sink

- A transparent cover with closure detection system

- The hydraulic circuit including the pressurization system

- The electrical cabinet

- Mobile control panel including screen, keyboard and mouse

sample burst pipe

Burst-tested hose

screen bench burst plastic tubes

Screen for pipe bursting bench

bench-cracking-tubes-plastics

pipe-eclate-vessie-bank-eclatement

Burst pressure hose on test bench

Crash-Tube – Tube bursting bench

Crash-Tube - Tube bursting bench

crash-tube-feeding

Crash-Tube power supply

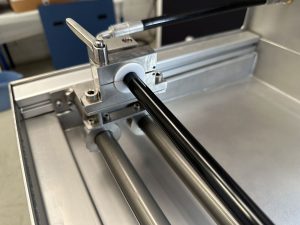

Tube attachment – Crash-Tube LF Technologies

Tube clamp - Crash-Tube LF Technologies

crash-tube-fixation-tube

crash-tube-fixation-tube

Inside the Crash-Tube

Inside the Crash-Tubre

crash-tube-LF-Technoloiges

crash-tube-LF-Technoloiges

Advantages of Crash-Tube

Intuitive software

The pressure generator allows for a gradual increase in pressure, as well as pressure holding stages, with controlled pressure (even in the case of creep under pressure of the tested product).

Tube connection tools

The tooling for connecting plastic tubes easily adapts to various diameters and lengths of tubes, without constraining the ends.

TECHNICAL CHARACTERISTICS of the Tube Bursting Bench

Specifications | Crash-Tube 100S | Crash-Tube 200S | Crash-Tube 200L |

Hydraulic performance | |||

Maximum pressure | 100 bar | 200 bar | 200 bar |

Pressure regulation accuracy (steady state) | 1 bar | 1 bar | 1 bar |

Pressure measurement accuracy | 0,1 bar | 0,1 bar | 0,1 bar |

Maximum pressure ramp up | 70 bar/min | 70 bar/min | 70 bar/min |

Max flow | 500 cm3/min | 250 cm3/min | 250 cm3/min |

Pressure generator volume | 500 cm3 | 250 cm3 | 250 cm3 |

Test fluid | Eau | Eau | Eau |

Tube diameters tested | Ø3 to 20 mm (other diameters on request) | Ø3 to 20 mm (other diameters on request) | Ø3 to 20 mm (other diameters on request) |

Bench dimensions | |||

Width | 1 750 mm | 1 750 mm | 2 250 mm |

Depth | 980 mm | 980 mm | 980 mm |

Height | 1 365 mm | 1 365 mm | 1 365 mm |

Usable length of the test area | 1 000 mm | 1 000 mm | 500 mm |

Customer applications

Would you like to find out more about hydraulic test benches?

Find out everything you need to know and much more!

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

COMPLEMENTARY SOLUTIONS

Discover our complementary hydraulic test benches for a complete and precise test