WHAT IS WATER HAMMER ?

Water hammer represents a sudden pressure surge within a hydraulic conduit (pipe, hoses used in faucets). This situation occurs when there is a sudden change in water flow, for example, when a valve is quickly closed. This hydraulic pressure variation can cause significant damage to pipes and appliances connected to them. Understanding and anticipating this phenomenon is therefore essential for the safety and durability of hydraulic infrastructures.

LF Technologies: Expertise in Water Hammer

Understanding and managing water hammer phenomena are decisive in ensuring the durability and safety of pipeline networks. LF Technologies offers manufacturers of hydraulic equipment specialized test benches that help understand and evaluate the behavior of their products under real situations. These benches are characterized by their precision and performance, which are essential for ensuring an accurate analysis. They allow for testing the resistance of products like faucets and other sanitary equipment to water hammer. LF Technologies does not limit itself to testing the mechanical resistance of hydraulic components; we also evaluate their propensity to generate water hammer themselves, thereby contributing to the design of robust and reliable hydraulic systems. By collaborating with LF Technologies, sanitary component manufacturers protect against the risks associated with water hammer, thus reinforcing the integrity of their hydraulic and sanitary components.

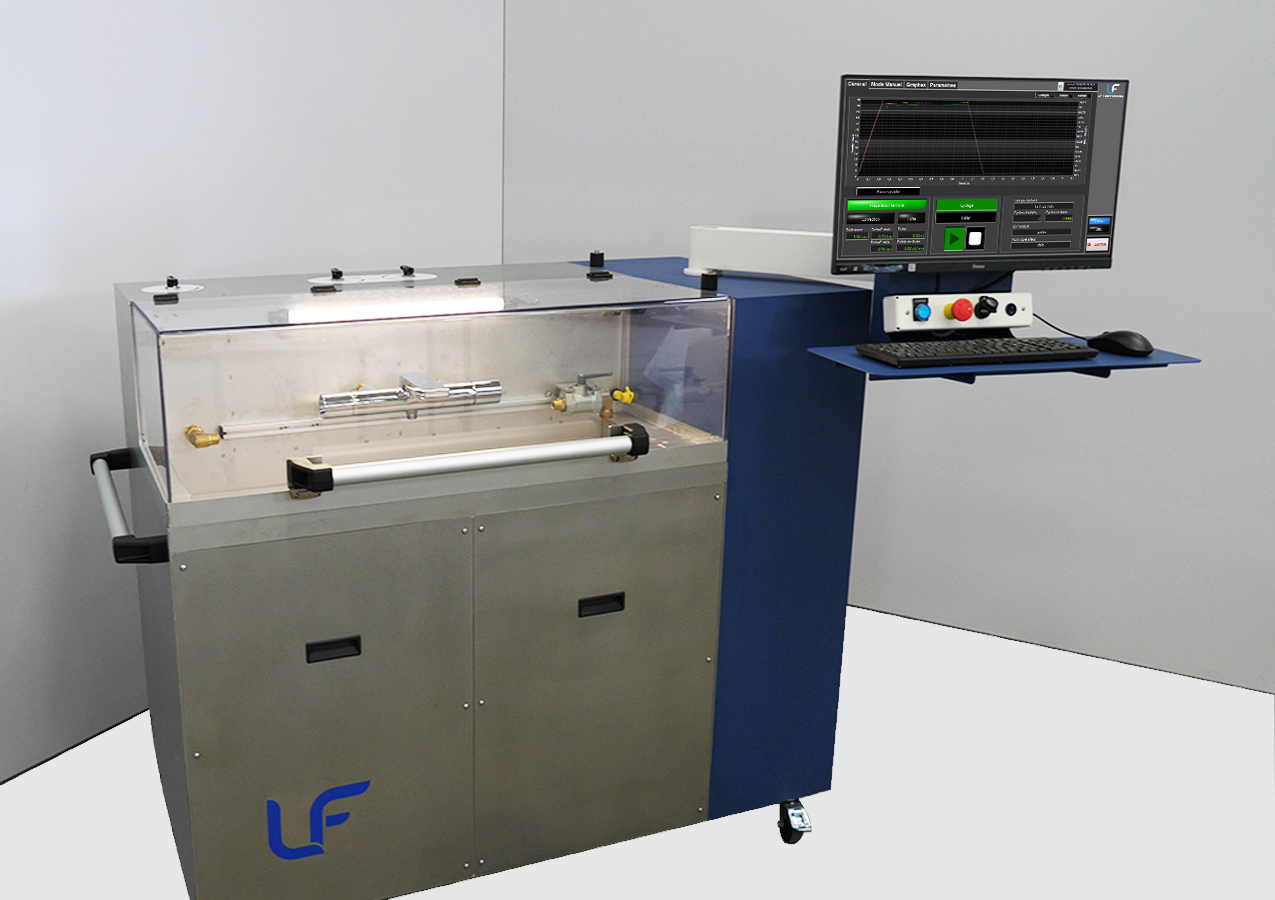

Our key test bench for water hammer testing – HYDROSHOCK

The offered solutions are benches that apply cyclic and static pressures at high intensity. Their purpose is to simulate a water hammer by applying a sudden pressure variation to the tested product.

The integrated pressure generator is designed to generate a rapid and controlled pressure surge using a motorized servo-dynamic system. This unit, key to the process, accelerates a piston that pressurizes the tested product, thus generating a pressure peak that simulates that caused by a water hammer, which can be automatically repeated to study the product’s resistance to multiple solicitations. The control over the dynamics of the generator allows for adjusting the high and low pressures of the cycle as well as the rise and fall times of pressure and the durations of the plateaus (trapezoidal cycle).

- Standard tests according to standards (Example NF077-doc tech 3)

- Programmable pressure cycles

- Quick and easy installation of taps and fittings of any shape

- Automatic shut-off in the event of leakage from the product under test

- MAXIMUM STATIC PRESSURE up to 200 bar

- MAXIMUM CYCLE PRESSURE from 30 to 100 bar (with near-instantaneous pressure increase < 0.3s)

The device operates independently of any connection to a supply or disposal network.

Bench developed to meet these standards:

NF077-doc tech 3

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Customer applications

Discover LF Technologies know-how through our customer applications.

They trust us

Principles and Benefits of Water hammer Testing

Implementing water hammer tests is fundamental to ensure the reliability, durability, and safety of hydraulic circuit components, especially in sanitary networks. These tests are even made mandatory by some standards or quality marks (e.g., NF mark for faucets). LF Technologies test benches allow companies to test and evaluate the behavior of their products under these extreme conditions.

Operation of a Water Hammer Test

The uniqueness of LF Technologies’ water hammer test benches lies in the use of a syringe controlled by a high-dynamic servo motor. This technology provides both good dynamics (extremely short pressure rise and fall times) and very high precision control without any adjustment by the user.

This technology, coupled with our self-learning system, allows for cyclic water hammer tests, with automatic adjustment of the dynamics to ensure perfect repetition of pressure cycles despite variations in the behavior of the tested product.

The high precision of our system ensures that the tests conducted match the specifications of the standards.

Our Approach to Water Hammer Tests

LF Technologies’ approach to water hammer tests is characterized by a deep understanding of physical phenomena in hydraulics. By accurately identifying the characteristics of the products to be tested and the test conditions, we offer several types of test benches to optimally simulate water hammers for any application.

LF Technologies’s Expertise at the Service of Hydraulic Safety

Water hammer tests play a crucial role in preserving the integrity of hydraulic systems. With LF Technologies, professionals designing sanitary equipment have a reliable and expert partner on these issues, capable of providing advanced and customized testing machines. Our experience, combined with deep expertise in the field, provides assurance against the risks associated with water hammers. Whether it’s to test the resistance of pipelines or to evaluate the performance of hydraulic components.

Advice from our experts

Would you like to find out more about hydraulic test benches? Find out everything you need to know and much more!