The Unique Development

Of our Own Electronic Acquisition Cards

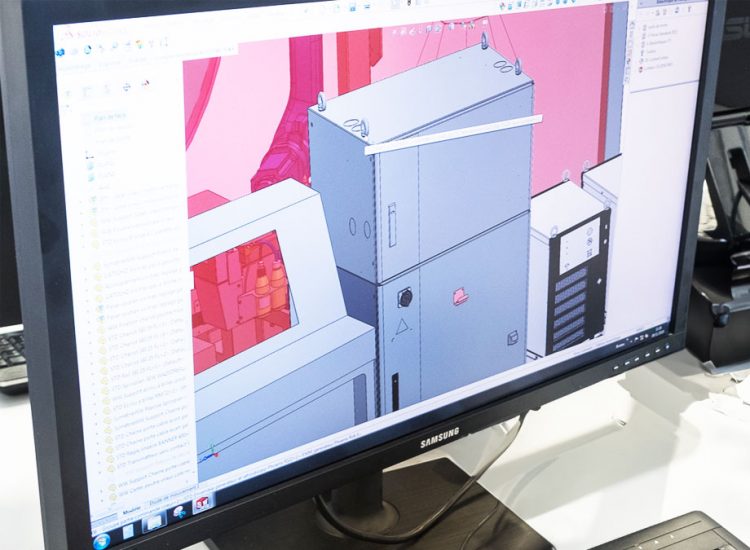

LF Technologies designs and manufactures your test benches and modular production machines from A to Z, i.e.from the redefinition of the specifications to commissioning on site, including the various stages of desig, electrical, mechanical, hydraulic and computer studies, programming and assembly and wiring.

Our production machines and our hydraulic and mechanical test benches are all PC-controlled via customised software.

the synergy of 3 skills centres

hydraulic test benches

Mechanical test benches

SPECIAL MACHINES

Your turnkey project

Discover the different stages of our support, from drawing up specifications to commissioning.

LF Technologies is

LF Technologies at your service

LF Technologies has expertise in revamping, industrial design andHMI, with the aim of offering you reliable, easy-to-use equipment.

RETROFIT

This service enables you to keep your machine up to date with the latest innovations, at lower cost, because we only change what's necessary.

INDUSTRIAL DESIGN

Mechanical design

Controlling the production line

Uniquely adapted models

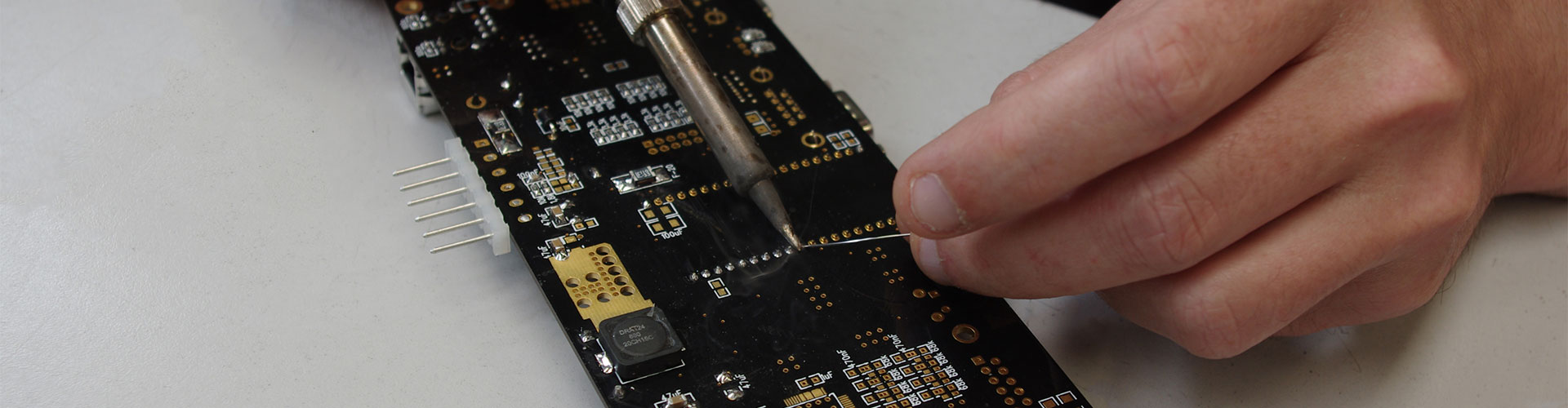

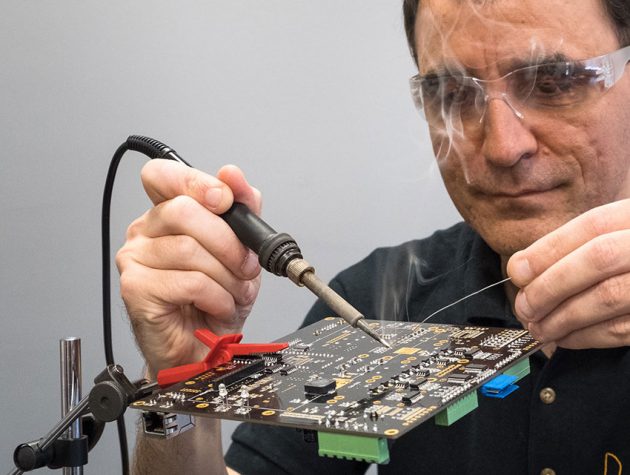

Whatever the position of our technicians, they master the manufacturing chain of the overall machine and therefore also its technical constraints. Thus, and always with a view to meeting your needs as best as possible, our electronic engineers, in collaboration with our project managers, design the acquisition cards necessary for building your test bench or production machine. Developing our own electronic boards in-house allows us to save a considerable amount of time, optimise the choice of electronic components according to the desired performance criteria and ensure perfect control of production.

Our electronic boards are unique models adapted to your application. They are developed in correlation with current technologies and according to the dimensions and functions of the various electronic components.

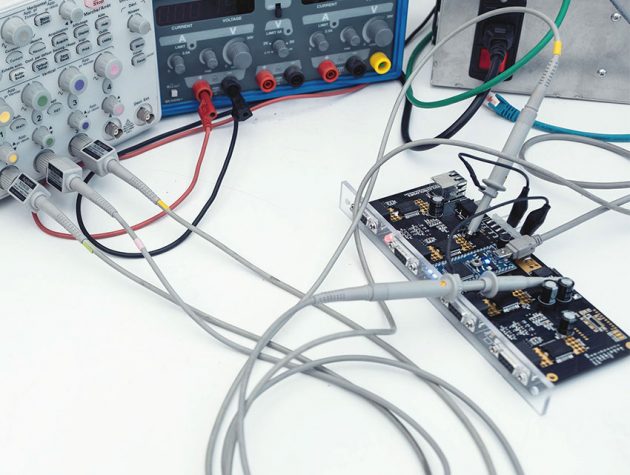

We test our electronic boards directly on the applications to which they are dedicated, in order to immediately make the necessary modifications if necessary, and to ensure the good behaviour of the components used.