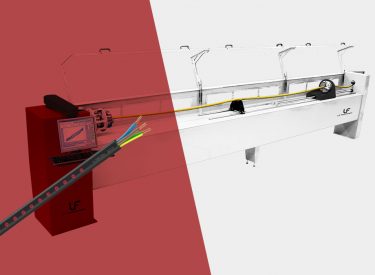

Continuous peeling bench

- The thermoplastic composite segments are transferred directly from production to the test area.

- Less than 5 seconds from production start to results

- The test machine is located directly on the production floor, so no external laboratory is required

- Patented system wins JEC Awards 2016 for innovative technology

Products tested

Sector of activity

Main functions

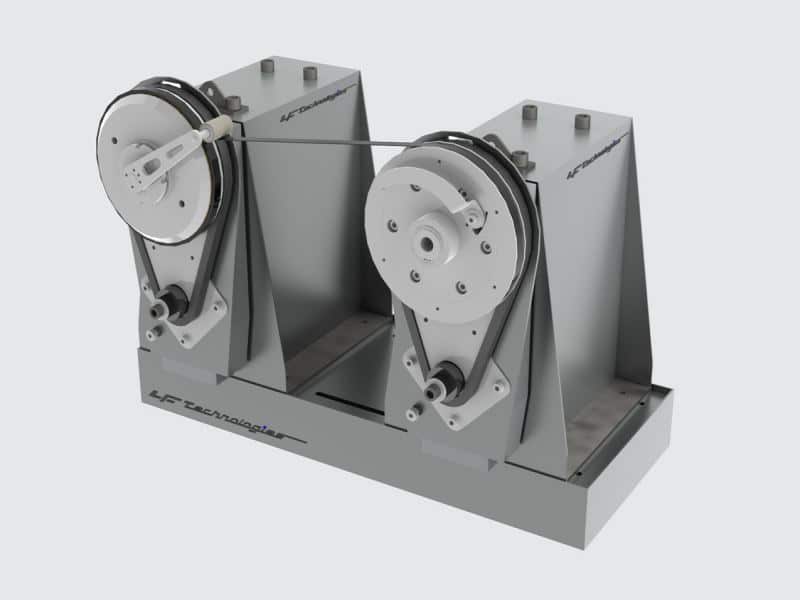

The peel tester is used to continuously measure the adhesion energies of thermoplastic laminates in order to test and optimise the bonding process. The principle of winding and gluing a composite strip is a technology that is increasingly used in the industrial sector, as it offers greater productivity. In order to optimise the quality of the bond between the composite layers and certain physical parameters such as pressure, temperature and heat transfer, LF Technologies has developed a continuous peeling bench. This highly innovative system offers highly accurate analysis of interlaminar adhesion and debonding force. The machine can be installed directly on the production floor to evaluate the adhesion parameters of thermoplastic composites in real time.

Operating mode

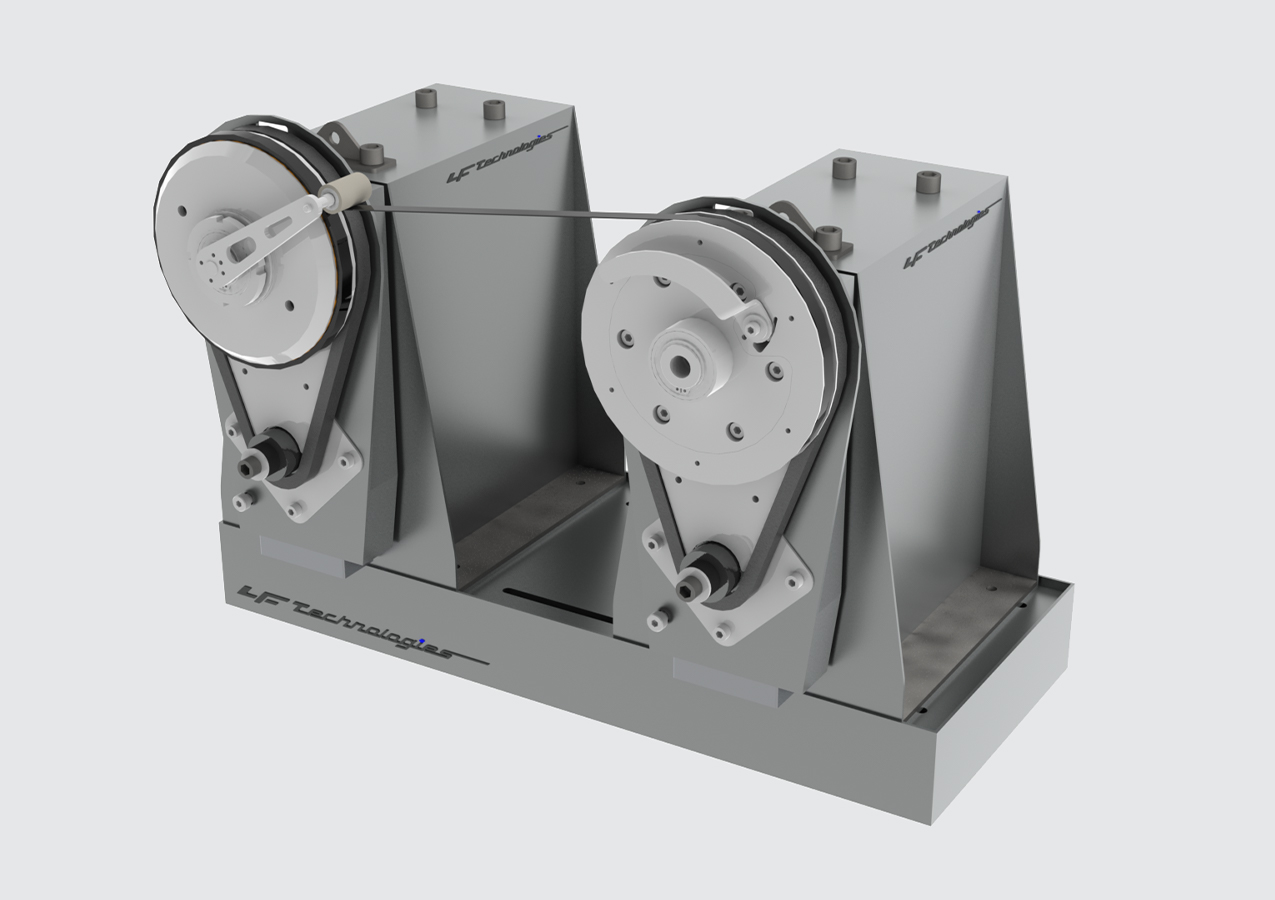

The continuous peeling bench unwinds the composite strips using a speed-compensated drum, while the composite sample is held in rotation by a second drum whose torque is also controlled. The peeling angle is set by the operator and controlled to prevent the carbon fibers from breaking, thus enabling continuous peeling. The higher the resistive torque, the more tangential the unwinding, and vice versa.

MPC – Continuous peeling bench – LF Technologies

MPC - Continuous peel tester - Mechanical test bench

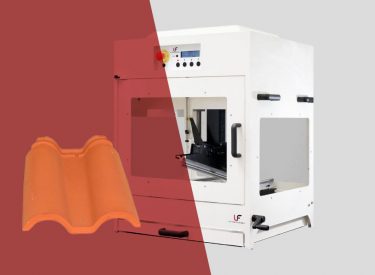

Carbon tubes

All types of composite tubes manufactured by bonding successive layers.

Continuous peeling bench

The peel tester is used to continuously measure the adhesion energies of thermoplastic laminates in order to test and optimise the bonding process.

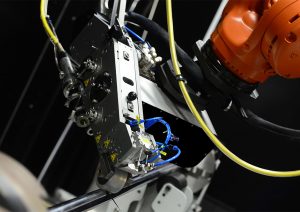

Winding of carbon parts

Adjustment of welding parameters for wound carbon layers.

No preparation

The thermoplastic composite segments are transferred directly from production to the test area.

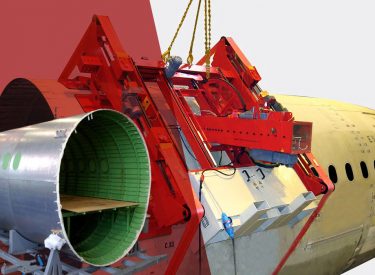

Aerospace

Checking the bonding of composite parts.

Advantages of the continuous peeling bench

Time saving

It takes less than 5 minutes from production start to results.

Lower test costs

The test machine is located directly on the production floor, so no external laboratory is required.

Patented system

Patented measuring principle, awarded for its innovative technology at the 2016 JEC Awards.

TECHNICAL SPECIFICATIONS of the Continuous Pelage Bench

Specifications | MPC |

Max. torque | 500 N.m |

Torque measurement accuracy | 0,25 N.m |

Accuracy of resultant force measurement | < 2,0 N |

Speed of rotation | 0 to 2.5 rpm |

Length | 770 mm |

Width | 460 mm |

Weight (without tools) | 100 kg |

Engine power | 2 x 400 W |

Power supply | 230 VAC 50-60 Hz |

Customer applications

Would you like to find out more about mechanical test benches? Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Explore our complementary products to get the most out of your creep test bench! Discover innovative solutions to further enrich your experience and optimize your results.