Horizontal Drop Test

- Simulation of very large masses (up to 200 tonnes)

- The machine has a small footprint and requires no civil engineering.

- Short set-up, assembly and disassembly times

- Machine protected by a hydraulic stop; no suspended load thanks to its horizontal position

Products tested

Sector of activity

Main functions

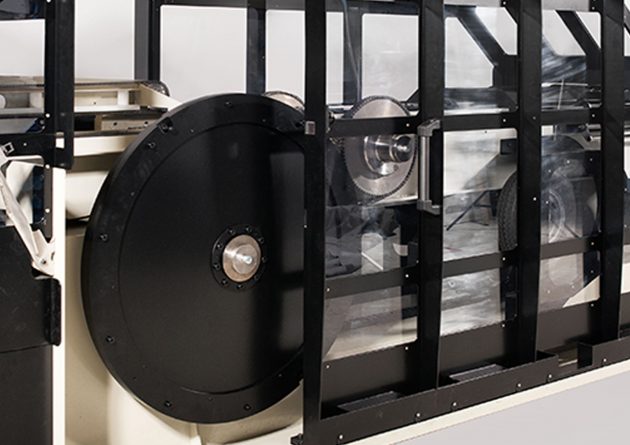

The horizontal drop shaft (dynamic shock bench) enables linear shocks with adjustable energy, speed and mass. Its revolutionary heavy weights simulation system makes it possible to carry out impact tests corresponding to a collision with a mass of 40 to 200 000 kg at a speed adjustable from 0.5 to 9 m/s thanks to flywheels of a mass of less than 200 kg. A high-frequency acquisition ensures the recording of the force/position curve at 100 kHz and the calculation of the absorbed and restored impact energies.

Operating mode

Using the calculation module, the user selects a weight to be simulated and an impact speed or energy. The software then automatically indicates which flywheel to use. The automatic launcher system accelerates the flywheels to the right speed, the striker is automatically engaged on the flywheels motion. The system is self-protected by a detachable automatically triggered hydraulic stop.

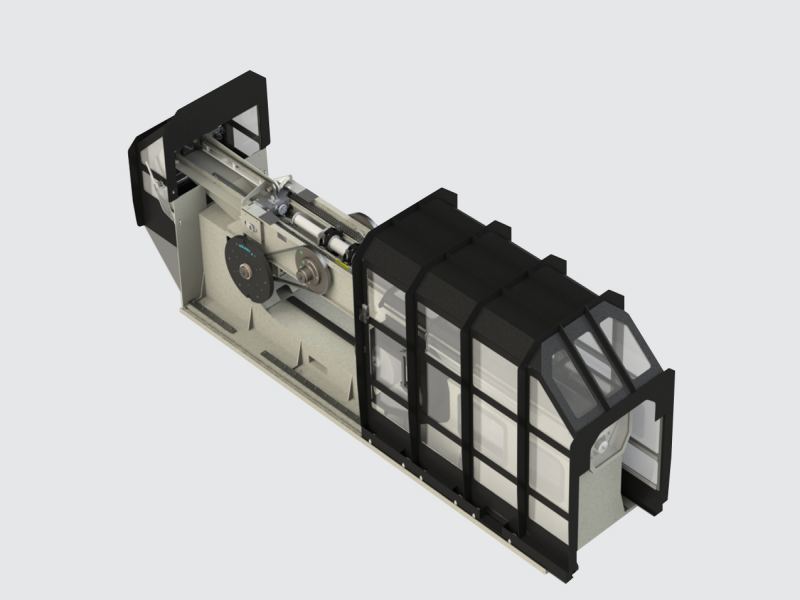

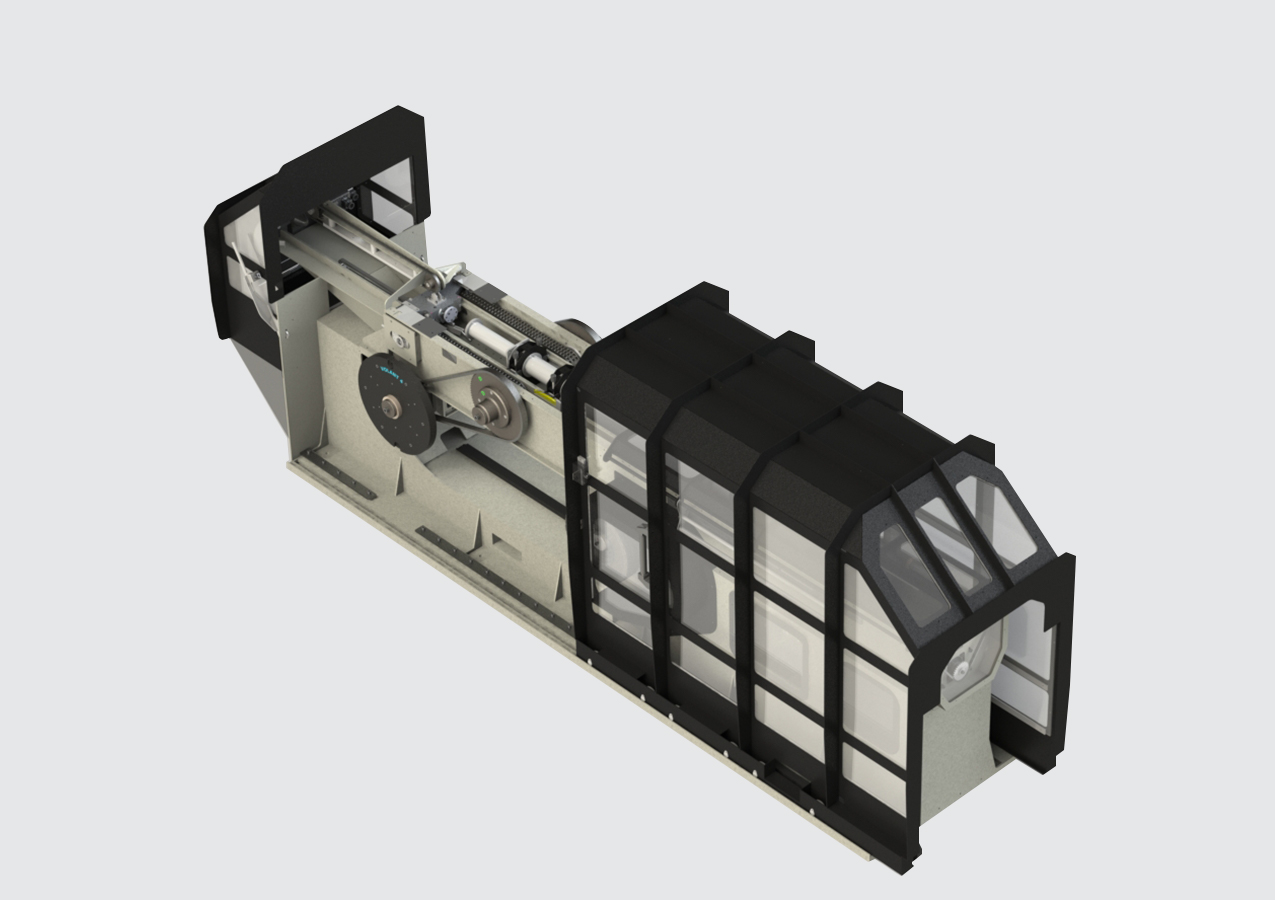

Horizontal drop shaft

The dynamic shock bench enables you to produce linear shocks with adjustable energy, speed and mass.

Location

With a capacity of 50,000 J and a length of 5 m, the machine takes up very little space and requires no civil engineering.

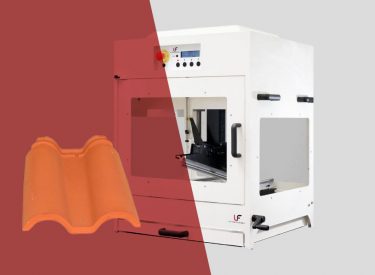

dampers

Dynamic behaviour of viscoelastic dampers for industry.

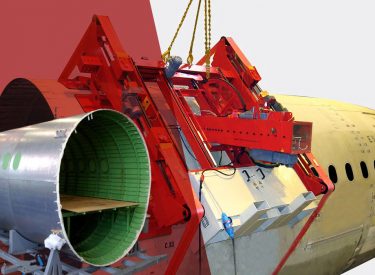

Crane stop

Simulation of an impact of an overhead crane on its end stops.

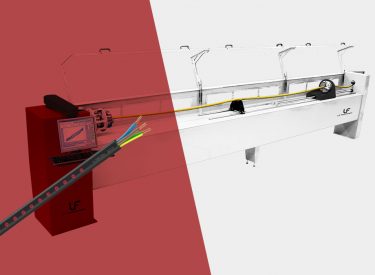

Horizontal Chute

For a major manufacturer of shock absorbers, LF Technologies designed a test bench for simulating dynamic shocks of up to 50,000 J, with adjustable mass and speed. Various types of shock absorber (landing gear, silentbloc, etc.) can be tested on this static and dynamic test bench.

Advantages of the Horizontal Drop Well

Shock absorber

Checking the operation of shock absorbers for wagons.

Mass simulator

Simulation of very large masses (up to 200 tons).

Speed

Setup, assembly and disassembly times are kept to a minimum.

Security

Machine protected by a disengageable hydraulic stop. No suspended loads thanks to its horizontal position.

TECHNICAL SPECIFICATIONS of the Horizontal Drop Well

Specifications | MCH |

Max. energy | 50 000 J |

Simulated mass | 40 to 200,000 kg |

Impact speed | 0.5 to 9 m/s |

Max. impact force | 150 000 N |

Clutch release force | 1 000 - 150 000 N |

Customer applications

Would you like to find out more about mechanical test benches? Find out everything you need to know and much more!

COMPLEMENTARY SOLUTIONS

Explore our complementary products to get the most out of your creep test bench! Discover innovative solutions to further enrich your experience and optimize your results.