Mechanical Torsion Test Benches

A torsion test bench is an equipment designed to subject samples to torsional moments in order to measure their resistance and behavior under different mechanical stresses. There are several types of torsion test machines depending on the intended application:

- Quasi-static test benches: They allow applying a progressive torsional moment at a low speed to create a torque/torsion angle curve.

- Cyclic test benches: They subject the sample to cycles of alternating torsion with variable or constant loads, depending on the type of test performed.

- Multi-axis test benches: They allow performing tests combining several types of solicitations (torsion, tension, compression) simultaneously or sequentially.

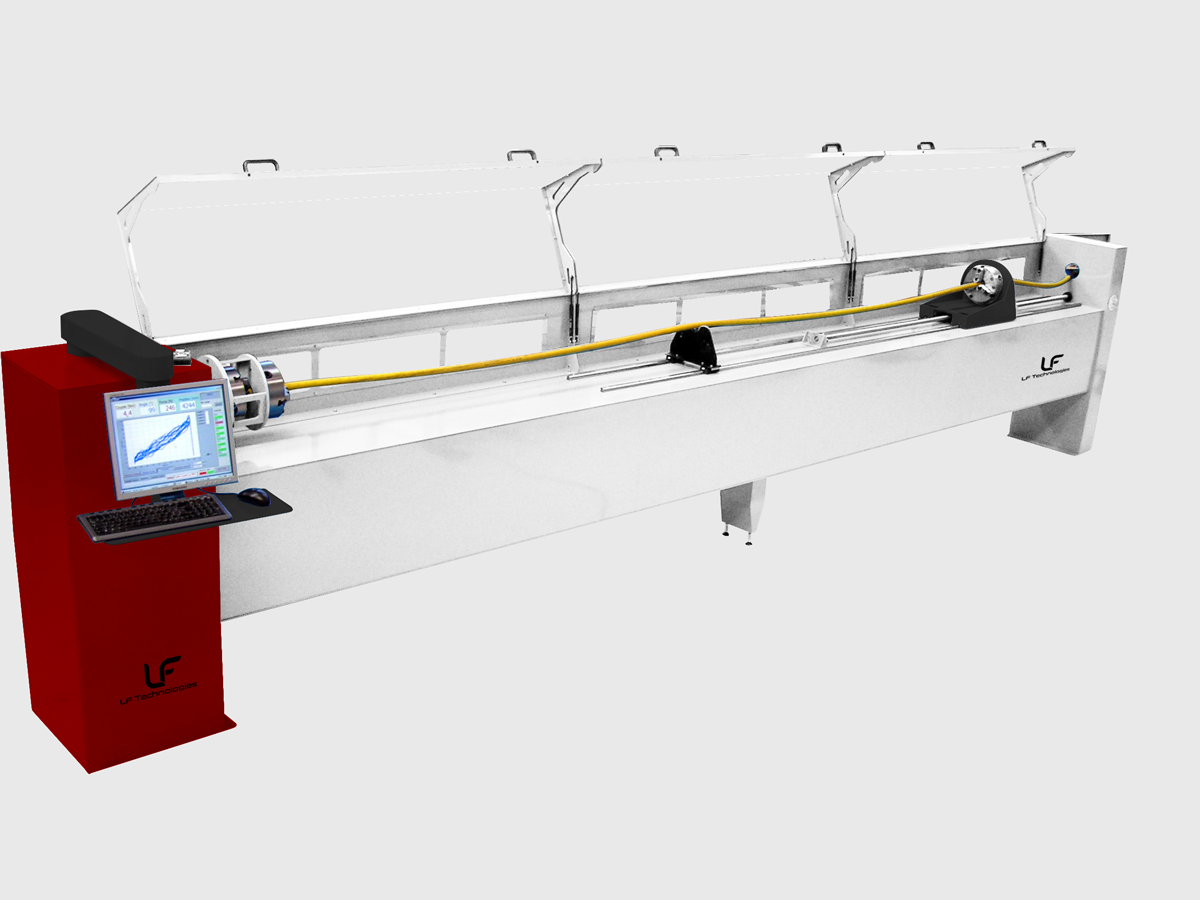

LF Technologies’ torsion test benches are equipped with precise measurement and control systems, which allow recording the torsion levels reached during the test, as well as the deformation and possible rupture of the sample. This information is essential to study the behavior of your materials and determine their resistance to the application you have planned for them.

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Customer applications

Discover LF Technologies know-how on torsion test benches through our customer applications;

Exploring Torsion Test Benches: Features and Applications

Introduction to Torsion Test Benches

Torsion test rigs play a crucial role in the characterisation of materials and products subjected to deformation stresses; These machines measure the torsional stiffness coefficient and the deformation energy, providing essential data for understanding the variation of the torsion angle under load; Configurable via a control console, they can be used to define parameters such as rotation speed, minimum and maximum angles, torque and number of cycles, facilitating precise, detailed analysis;

Technical Features of Test Benches

Torsion test benches stand out for their technical specifications, adapted to the needs of each application:

- Bench Capacity: The capacity, expressed in newton-meters (Nm), corresponding to the maximum torque that the bench can apply, is essential for properly calibrating the bench according to the application.

- Maximum Angle: Corresponding to the maximum deformation angle sought. Depending on the applications, this angle can be very small (high torsional rigidity) or infinite, especially for friction measurements (example: friction of a joint).

- Measurement Resolution: This specification emphasizes the precision of deformation measurements, ensuring data reliability for in-depth analyses.

- Rotation Speed: The maximum and minimum speed, in degrees/s, is crucial to simulate dynamic usage conditions.

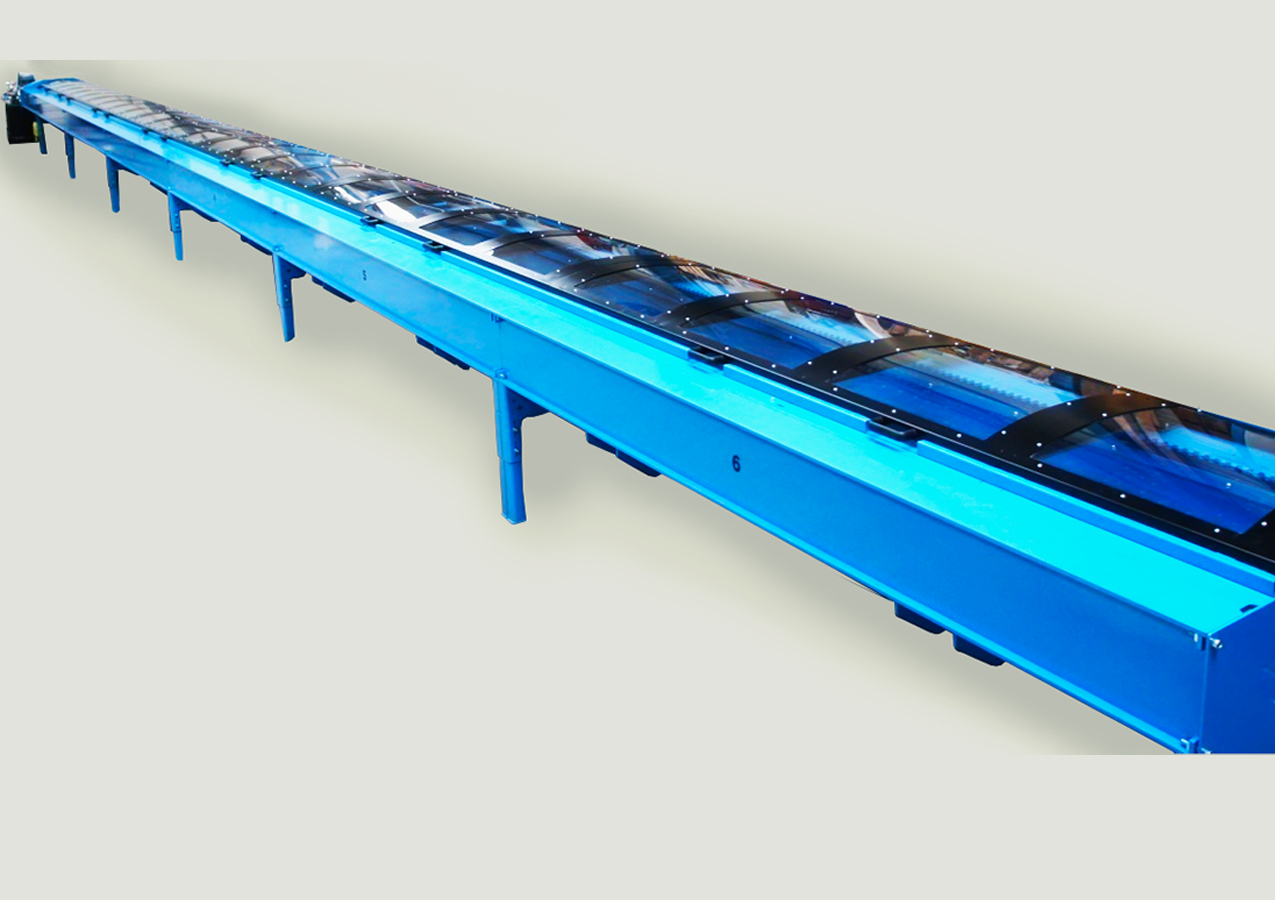

- Continuous rotation test: to carry out torque resistance tests during continuous rotation, for transmission systems;

- Adaptability: The benches offer flexibility to test various sample sizes thanks to modular clamping systems.

- Automation and Digital Control: These features increase the flexibility and reproducibility of tests, improving operational efficiency.

Diverse Applications of Test Benches

Torsion test machines are applied in a multitude of sectors, demonstrating their versatility and importance:

- Aerospace and Space: They allow testing the resistance of materials and components to torsional solicitations, ensuring safety and reliability.

- Automotive and Transport: To test the energy absorbed by a deformable piece in torsion.

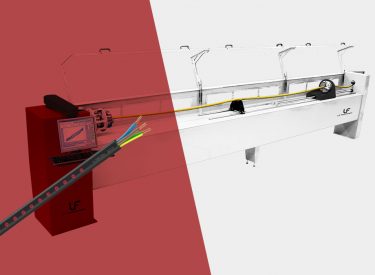

- Electrical Cables: To measure the lifespan of a cable subjected to torsion, especially in combination with a tensile effort.

- Composite Materials: Torsion tests are vital to understand the behavior under stress of new composites.

- Elastomeric Materials : To measure the friction evolution of a rotary joint over its lifespan.

Torsion test rigs are indispensable tools for analysing materials and products in a wide range of industrial sectors; Their ability to accurately measure strength and torsional behaviour enables engineers and researchers to develop safer, more durable and higher-performing materials and components; By offering a wide range of technical features and adaptability to diverse applications, these test machines support innovation and quality in research and development as well as industrial production;

LF Technologies Torsion Test Benches: A Guarantee of Quality and Reliability

In the world of torsion testing, LF Technologies offers a wide range of torsion test benches designed for a multitude of applications; Choosing a torsion test rig from LF Technologies means choosing a test solution perfectly adapted to your specific application, using technology specially dedicated to your product and your unique test conditions; Our engineers will work with you to select the most appropriate technology, so that you get an efficient machine that simulates the real conditions in which your products are used; Our team is also available to help you define your specifications, whether to assess the real conditions of use of your product, or to adapt our machines to a standardised test based on a quality standard; This personalised approach, combined with our rigorous design and manufacturing processes, forms the basis of our commitment to providing you with high-quality, durable test solutions; Finally, user safety and customer service are key priorities for LF Technologies, which guarantees first-rate technical support and after-sales service;

Expert advice

Explore our blog dedicated to the world of mechanical test benches.

Immerse yourself in engineering excellence and discover the latest advances, tips and trends in the field.