Our assembly modules

What is an Assembly Module ?

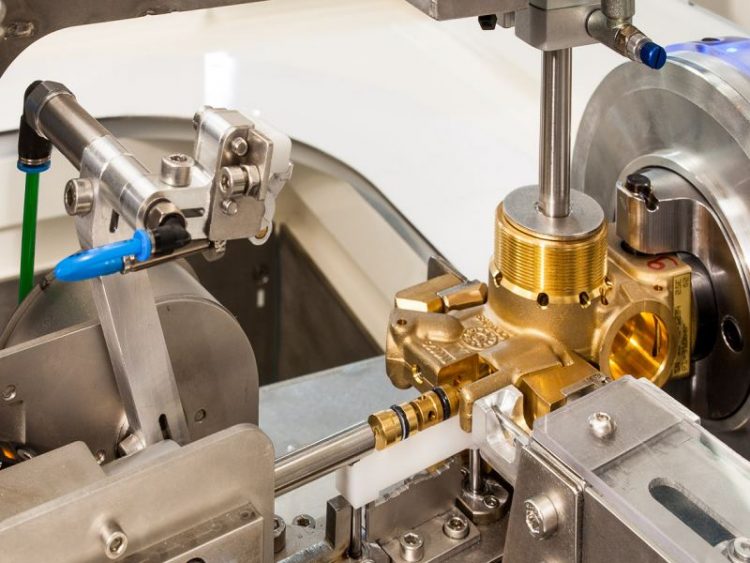

An assembly module is a system designed to perform a specific task related to the assembly of parts and components to create a finished product. It can be used to join two mechanical parts or assemble various components of a finished product. Special assembly machines may incorporate several modules to perform different operations, such as:

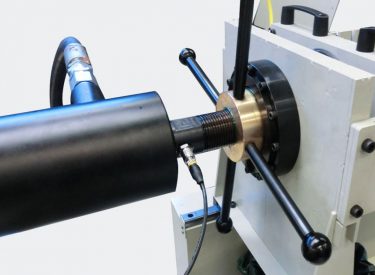

- Screwing : attaching a screw element into a body.

- Press-fitting : forceful insertion.

- Gluing: adhesive application and holding the piece during drying.

- Welding: joining two elements together.

These machines optimize productivity and the quality of production processes by automating manual tasks, thereby reducing the time needed to assemble products and minimizing assembly errors.

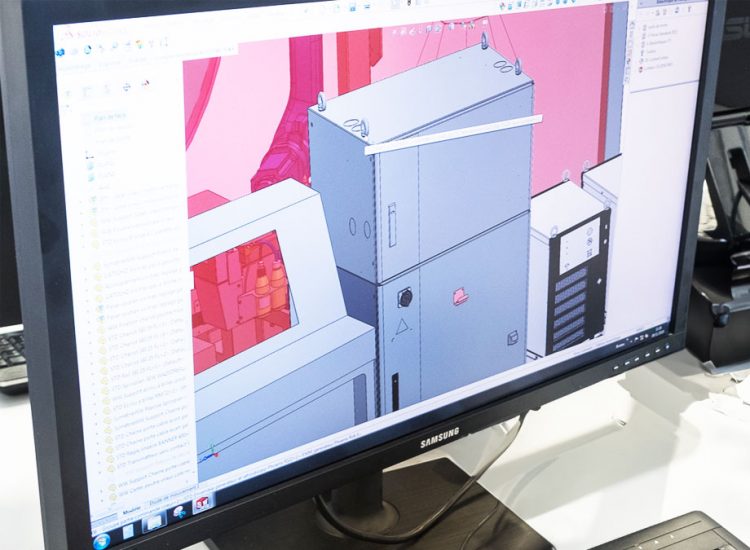

Assembly Modules: Excellence according to LF Technologies

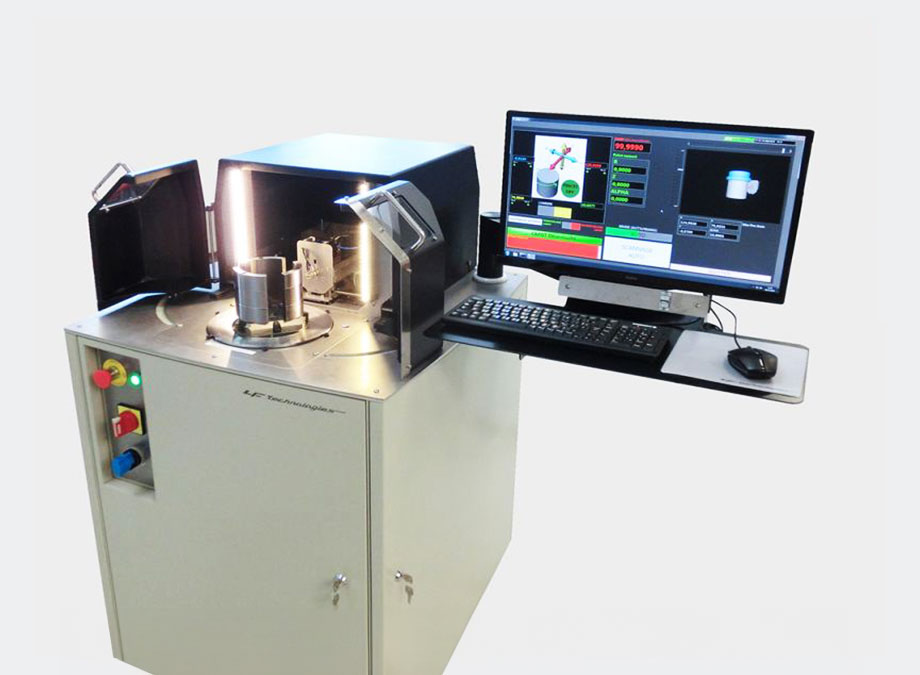

LF Technologies integrates optimized assembly modules for specific tasks into its special machines. The use of specific modules, designed according to the client’s specifications, ensures the machine’s high efficiency with an optimized solution for the application.

Our multidisciplinary experience allows us to offer a multitude of technical solutions and choose the one best suited to your constraints.

Your turnkey project

Discover the different stages of our support, from drawing up specifications to commissioning.

Customer applications

Discover LF Technologies know-how through our customer applications.

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

They trust us

Discovering Assembly Modules and Their Functioning

Assembly modules are more or less autonomous systems dedicated to an assembly task. Integrated into a special machine or a production line, they can perform operations such as screwing, press-fitting, gluing, welding, etc., on a wide variety of components and materials.

These modules are more or less autonomous but always controlled by a supervisory system that ensures the collaboration of the different modules with each other. On the same machine, assembly modules can be combined with handling, cutting, machining, adjustment, and automatic control modules.

Although assembly modules are very varied, they share common features:

- Controlled by an automatic program corresponding to a sequence of configurable unit functions.

- Real-time measurement of assembly conditions (screwing torque, position, press-fitting force…).

- Real-time reaction to variations in assembly conditions, through automatic servo control or self-regulation.

- Recording of measured data and automatic validation of the assembly operation’s quality.

- Data feedback to the supervision software for automatic storage and report generation.

The use of an automatic assembly module allows:

- Application of a reproducible assembly method.

- Measurement and qualification of the assembly quality for each produced piece.

- Assurance of traceability of assembly methods and validations.

- Elimination of non-ergonomic manual operations.

- Acceleration of processes.

Examples of Industrial Applications of Special Assembly Machines

Special assembly machines are used in numerous industrial sectors where they contribute to improving the production processes of complex products, here are some examples:

- Heavy industry: improving ergonomics by automating tasks that could cause musculoskeletal disorders.

- Mechanical industry: automatic completion of operations requiring rare expertise (e.g., welding) to compensate for a lack of labor.

- Medical industry: automated assembly allows for high traceability of product assembly operations. Each operation can be documented (assembly parameters, measurements and charts for each piece, automatic validity control, date/time of assembly, etc.)

- Construction industry: automation of manual processes to streamline assembly methods and improve the reproducibility of operations.

The Importance of Maintenance and Training on Special Assembly Machines

To ensure optimal operation and increased longevity of special assembly machines, it is essential to maintain them regularly and monitor their performance. A preventive maintenance program can prevent many problems that could cause unexpected production stops and harm the quality of assembled products.

On a production assembly machine, using modules facilitates these maintenance operations.

Today, special assembly machines offer efficient and flexible solutions to industries looking to optimize their production processes while improving their competitiveness. By combining different technologies, these equipments allow for increased automation and precision in performing complex assembly tasks.