Our machining and cutting modules

Cutting and Machining Modules for Special Machines: The LF Technologies Promise

LF Technologies integrates modules into its special machines that allow for cutting or machining operations. Our goal is to offer you optimized solutions, designed according to your specific needs, to ensure efficiency and quality in your manufacturing process. Efficiency is guaranteed, as our modules are custom-designed, specifically for your application, without superfluous functions. As for quality, it is achieved through meticulous selection of components and the implementation of intelligent control systems. These systems are capable of automatically regulating and adjusting machining programs to adapt to the variability of parts or different working conditions.

Cutting Module and Machining Module, Innovation at the Service of Industry

At LF Technologies, innovation is at the core of our identity. We understand that some projects require specific responses, far from standardized solutions. hat’s why we are committed to developing original and tailored approaches to meet the unique needs of your manufacturing process. Relying on our technical expertise, our team strives to design solutions capable of meeting unique challenges. We are by your side to find effective solutions together, leveraging our experience to face the unique challenges of your project.

Your turnkey project

Discover the different stages of our support, from drawing up specifications to commissioning.

Customer applications

Discover LF Technologies know-how through our customer applications.

3 axis machining centre

The 3-axis machining centre produced by LF Technologies automatically machines holes and mills aluminium profiles such as door frames and sills.

Do you have a project ?

I will be happy to advise you and propose solutions tailored to your needs.

Kevin Imberte

Special Machines Division

They trust us

Special Machines for Cutting and Machining

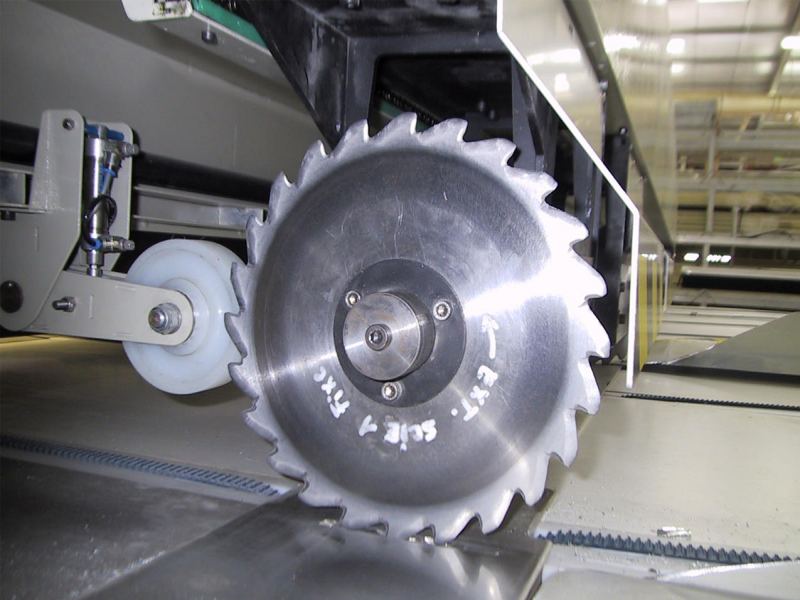

Discover the versatility and efficiency of our special machines designed for cutting and machining. Through innovative technology and customized solutions, we offer answers tailored to the most stringent requirements of your sector. Whether it’s processing delicate materials or performing complex tasks, our equipment is designed to provide unmatched performance and precision. Dive into the world of high-precision cutting with our abrasive wire module, a technology specially adapted for clean and precise cuts on a variety of materials.

High-Precision Cutting with the Abrasive Wire Module

We integrate cutting modules using abrasive wire technology into our machines, particularly for soft materials, such as foams and wools like polyurethane, polystyrene, rock wool, etc. Our abrasive wire cutting modules incorporate specific features to ensure high cutting precision, such as the self-adaptability of the feed rate and cutting speed, management of wire tension, and automatic detection of the raw piece’s edge.

Adaptive Machining to Solve Complex Industry Problems

Our machining modules incorporate automatic trajectory calculation systems, allowing for self-adaptive machining programs that adjust to variations in the parts being machined in real time, to improve machining precision, reduce cycle time, and decrease scrap rates.

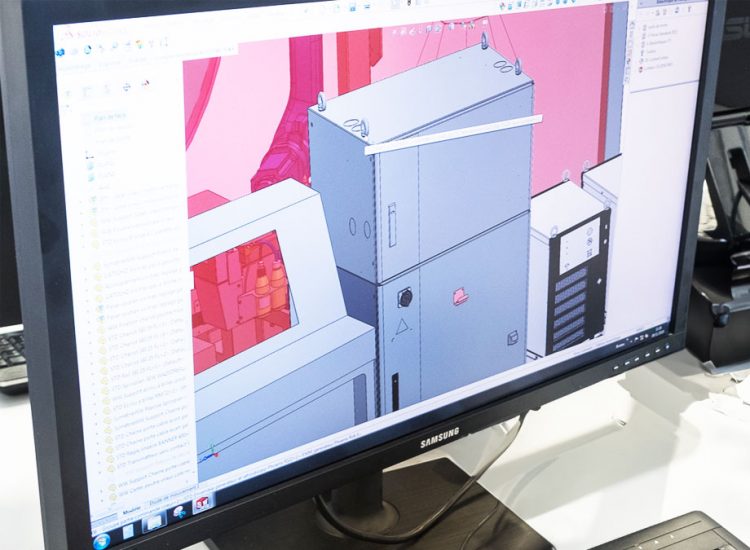

Integration of These Technologies in an LF Technologies Cutting and Machining Module

Turnkey Solutions for Easy Integration

Regardless of the proposed technologies, we always place utmost importance on the efficiency and ergonomics of our machines. Our priority is to design systems that simplify your operations and maximize productivity. We ensure that each solution is intuitive, easy to handle, and precisely adapted to your specific requirements, thus ensuring smooth integration into your work environment.

Enhanced Performance Through Intelligent Control

One key to the high performance of a machining module lies in its control system, crucial for simplifying both its use and programming, and for dynamically adapting to the specific demands of production. Intelligent control improves the quality and efficiency of machining, while reducing the time required for its programming.

Safety and Quality at the Heart of Design

In designing our modules, safety and quality are essential priorities. We commit to adhering to stringent standards to ensure user safety and product reliability. By adopting preventive strategies against risks while aiming to maintain consistent performance, LF Technologies strives to offer reliable and superior quality solutions, thereby meeting the specific needs of our clients while complying with industrial requirements.

Industrial Applications of a Versatile Cutting and Machining Module at LF Technologies

The cutting and machining modules can be integrated for a multitude of applications, in various industry sectors, such as:

- In the sanitary fittings sector: Associated with an adjustment bench, the machining module in the production of thermostatic cartridges allows for the creation of a mechanical mark positioned according to the adjustment made.

- In building insulation: Abrasive wire cutting to create custom foam insulation cuts.

- In railway construction: Automated sawing of aluminum honeycomb panels, integrated into our honeycomb stretching machine.

- In mechanical testing laboratories: Polishing module integrated into a mechanical testing machine, ensuring high reproducibility of specimen surfaces.

- In aeronautics: Use of a 5-axis robotic waterjet cutting for precise cutting of flexible parts without thermal constraints.