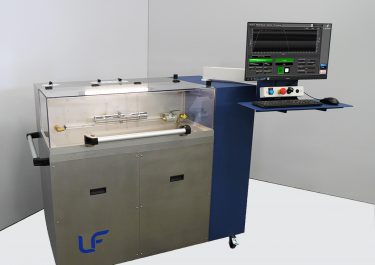

Cartridge adjustment bench in production

Sanitary fittings test bench for testing two thermostatic cartridges simultaneously.

Allows various measurements, antiscald tests, engraving of 38°C position, etc.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our customer is a European manufacturer of sanitary fittings (faucet heads, thermostatic cartridges, etc.).

Main functions

Objective

Design a valve test bench capable of adjusting and testing thermostatic cartridges, as well as locating the 38°C position.

PROBLEMATIC ISSUES

The adjustment bench must be equipped with several stations so that multiple cartridges can be tested and adjusted simultaneously by a single operator. The bench must be able to combine several testing functions with automatic temperature control.

SOLUTION AND RESULT

The bench proposed by our engineers is a production test and adjustment bench with simplified functions. It meets specifications for both cartridge adjustment and testing. During the automatic cycle, the following functions are performed:

Leak test

The pumps bring the water to the desired pressure, then the outlet and inlet valves are closed. The program then measures pressure drops in the thermostatic cartridges. Any leak detected instantly stops the test.

Temperature setting

The motorized actuator turns the cartridge temperature control until the desired temperature is reached.

Anti-scald test

The antiscald test ensures that the water flow is cut off in the event of loss of cold water supply. The bench can be used to set and test thermostatic cartridges on 2 stations, in masked time. Test results are saved in a file for production statistics. The bench is also equipped with an engraving system to mark the 38°C position, followed by a blowing system to remove excess water.

Tested product

Brass thermostatic cartridge

Plastic thermostatic cartridge

Tap cartridge production bench

Production bench used to adjust and control thermostatic cartridges.

This bench is used to : – Check the presence of seals by means of a leak test.

– Control hot and cold water pressure.

– Check that water supply temperatures are within the user-defined range.

– Check the flow rate setting.

– Carry out a mixed temperature test in the full hot position (C3 / ECAU standard).

– Operate the cartridge over its full operating range and check the operating torque.

– Automatically set the mixed water temperature to 38°C.

– Perform antiscald and hyteresis test.

– Mill the cartridge to locate the 38°C – Blow dry the cartridges.

Adjustment bench for thermostatic cartridges

Production bench used to adjust and control thermostatic cartridges.

This bench is used to : – Check the presence of seals by means of a leak test.

– Control hot and cold water pressure.

– Check that water supply temperatures are within the user-defined range.

– Check the flow rate setting.

– Carry out a mixed temperature test in the full hot position (C3 / ECAU standard).

– Operate the cartridge over its full operating range and check the operating torque.

– Automatically set the mixed water temperature to 38°C.

– Perform antiscald and hyteresis test.

– Mill the cartridge to locate the 38°C – Blow dry the cartridges.

OUR KEY TEST BENCH FOR THESE TESTS Automatic temperature control and test bench for thermostatic cartridges ThermControl-Auto

The thermostatic cartridges adjustment and test bench allows to test the behavior of a thermostatic cartridge (sealing, flow, antiscald) and to adjust the temperature control of the cartridge manually or automatically.

The manual thermostatic cartridges adjustment and control bench allows :

- an air and/or water sealing test

- the setting of mixed water temperature and flow rate

- the measurement of the mixed water temperature in full hot position

- sealing measurement

- measurement of antiscald and hysteresis

Bench developed to meet these standards:

EN-1112

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed by LF Technologies.