Dynamic impact test on railway shock absorbers

Shock and impact test bench for shock absorbers. Dynamic shock simulation, adjustable mass and speed !

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

The behaviour of these products is tested statically on a static bench and must also be tested at high speed (impact test), as the shock absorber’s reaction depends on the impact speed. Since the shock absorber’s reaction force is a consequence of speed and mass, the test can only be carried out using an ‘inertial’ system, i.e. an adjustable mass propelled at a controlled speed. During the impact phase, the movement of the mass against the shock absorber must be passive, with no external energy input;

The only existing solutions are a mobile trolley on a slope or an explosive-propelled trolley.

PROBLEMATIC ISSUES

- Simulation of the movement of highly variable masses launched at different speeds without the use of large masses.

- Machine protection in the event of a faulty device being tested

SOLUTION AND RESULT

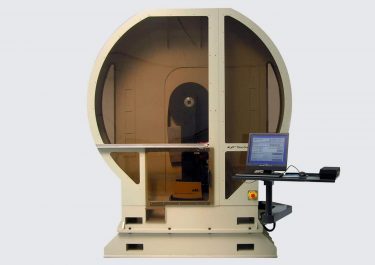

LF Technologies has designed and built a dynamic shock simulation bench up to 50,000 J, with adjustable mass and speed, enabling simulation from 50 kg to 200 T at 0.5 m/s to 10 m/s.

The bench consists of a frame on which a striker and a static stop slide, against which the shock absorbers under test are pressed.

The static stop is fitted with an automatic locking system to limit the maximum impact force to an adjustable value from 10 to 150 kN.

The shock absorbers to be tested are mounted in tooling that can also slide in the frame;

The striker is propelled by chains onto the shock absorber to be tested. These chains are driven by wheels fitted with interchangeable flywheels and motorised by a disengageable system.

It is the inertia of the flywheels and their mounting position (direct drive or via a gearbox) that determine the simulated mass.

Thanks to this dynamic shock simulation bench, our customer can simulate the damping of a very large mass, where previously it would have been necessary to use a wagon loaded with ballast weighing several dozen tonnes on a sloping railway track!

Products tested

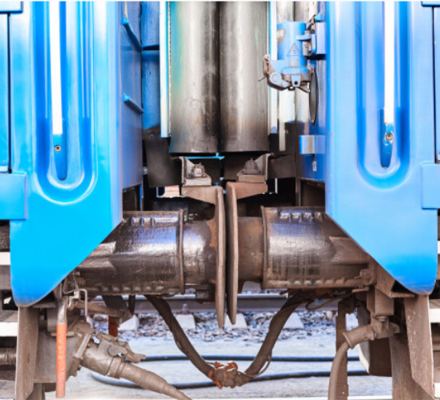

Shock absorber

This is a mechanical system that reduces the violence of an inertial shock. The shock energy is absorbed by the shock absorber, without rebound.

Depending on the application, these dampers are sized according to the speed and mass to be braked.

Shock absorber

Shock absorber

Silentbloc shock absorber

Silentbloc shock absorber

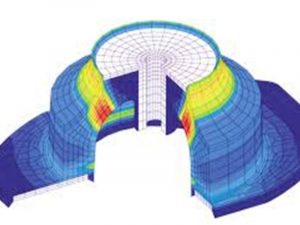

Calculated shock absorber force

Calculated shock absorber force

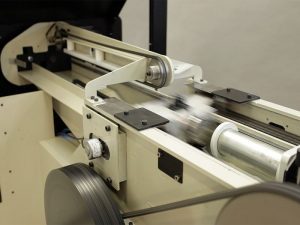

Shock absorber impact test

Shock absorber impact test

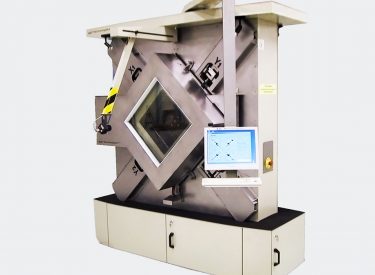

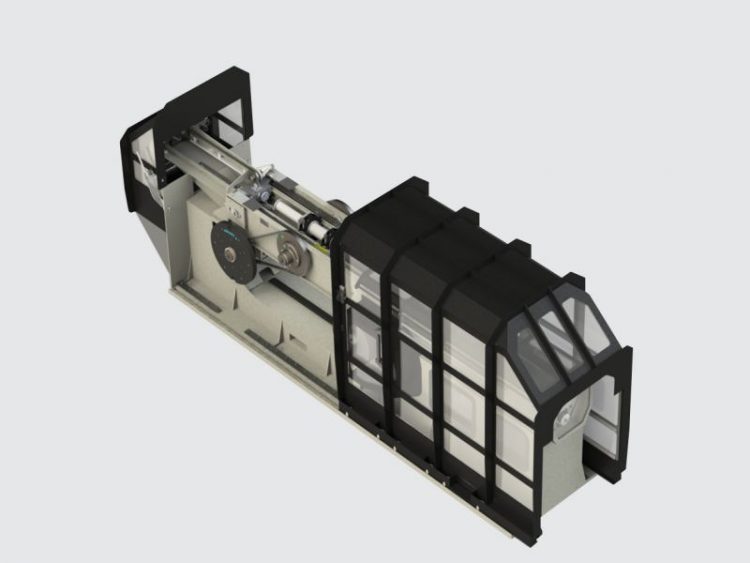

dynamic shock test bench

Overview of the dynamic impact test bench

Remote control panel

Remote control panel

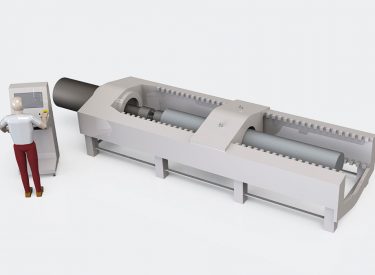

Dynamic shock bench – Horizontal drop well.

For a major manufacturer of shock absorbers, LF Technologies has designed a bench for simulating dynamic shocks of up to 50,000 J with adjustable mass and speed. Various types of shock absorber (landing gear, silentbloc, etc.) can be tested on this static and dynamic test bench.

Our key test bench for these tests Horizontal Drop Well MCH

The horizontal impact drop tester (dynamic shock test bench) allows to produce linear shocks with adjustable energy, speed and mass.

Its revolutionary heavy weights simulation system makes it possible to carry out impact tests corresponding to a collision with a mass of 40 to 200 000 kg at a speed adjustable from 0.5 to 9 m/s thanks to flywheels of a mass of less than 200 kg.

A high-frequency acquisition ensures the recording of the force/position curve at 100 kHz and the calculation of the absorbed and restored impact energies.

Using the calculation module, the user selects a weight to be simulated and an impact speed or energy. The software then automatically indicates which flywheel to use.

The automatic launcher system accelerates the flywheels to the right speed, the striker is automatically engaged on the flywheels motion.

The system is self-protected by a detachable automatically triggered hydraulic stop.

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.