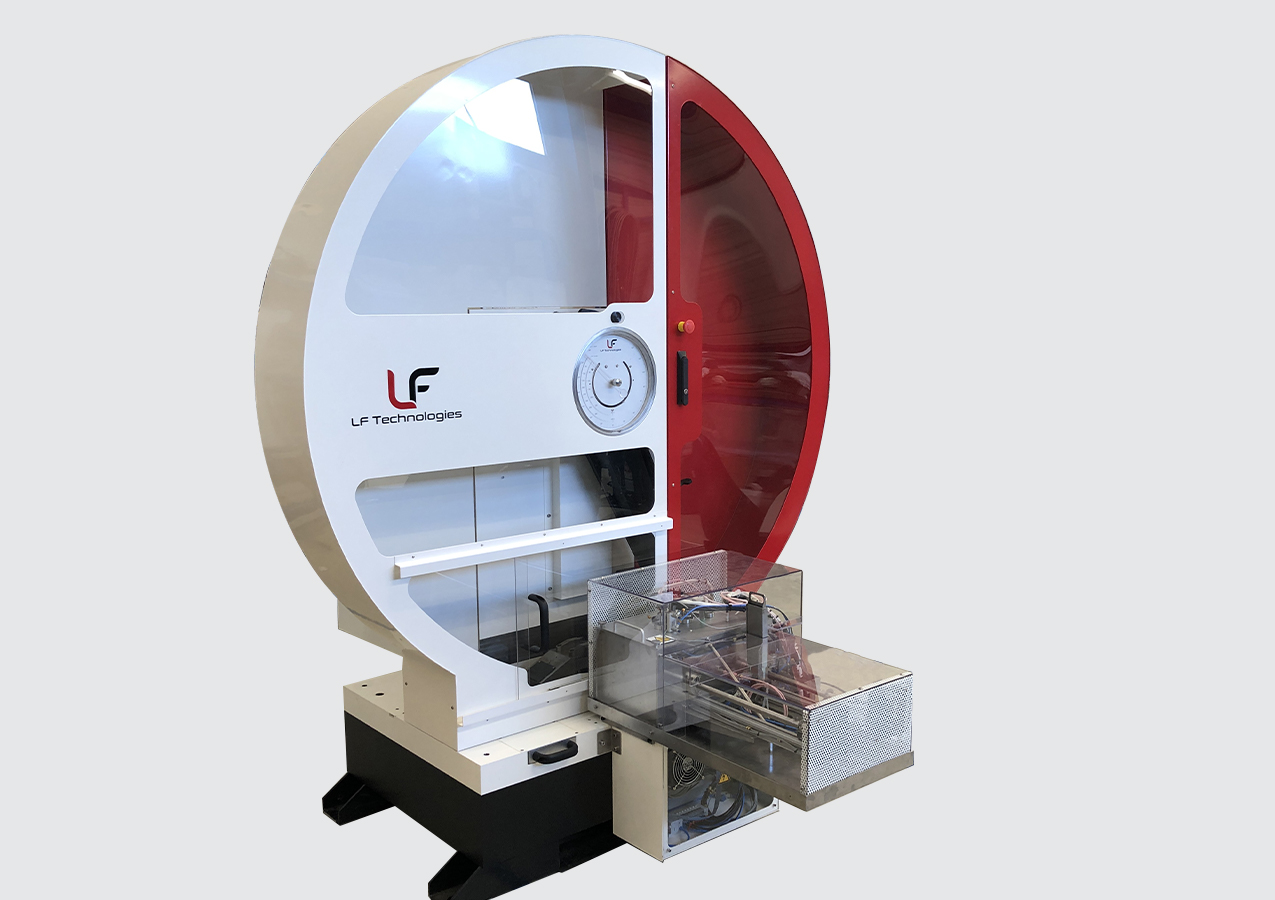

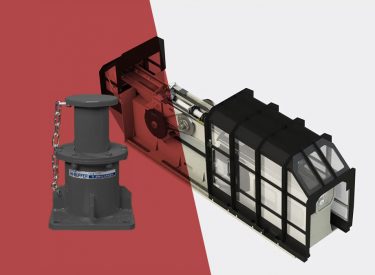

The shock test machines come in various configurations: horizontal shock test bench, drop impact testing machine, dynamic and static impactor, pendulum ram.

Shock & Impact tester machines

Shock and impact tester machines come in different forms: the Horizontal drop tower, vertical drop tower, as well as dynamic and static impactors or pendulum impact tester. Each configuration has been designed to meet specific needs, allowing the testing of a wide range of products of various sizes in many sectors such as sports equipment manufacturers or construction material tests.

Why conduct shock tests ?

In the industry, shock tests can be used:

- in R&D, to assess a product’s resistance during its design phase

- in destructive testing, to verify, (on a batch taken from the production line), the product’s ability to withstand a shock.

- in individual testing, to measure the characteristics of a shock absorption system (damper)

International Standards for shock and impact test benches

Some impact tests are defined by standards, particularly material resilience tests, performed on standardized specimens.

- ISO 148-1: Charpy resilience tests (impact bending test)

- ISO 14556: Charpy resilience tests (impact test rig) with force/deformation instrumentation

- ASTM D256: Impact resistance of plastics by Izod.

Beyond standard norms, LF Technologies supports its clients in proposing shock test benches that simulate the real conditions of shocks experienced by your products.

Customer applications

Discover LF Technologies’ know-how on impact test benches through our customer applications…

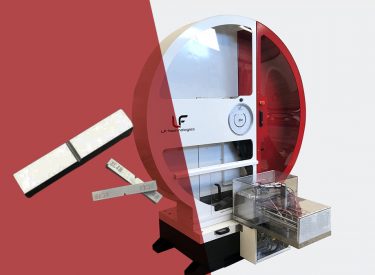

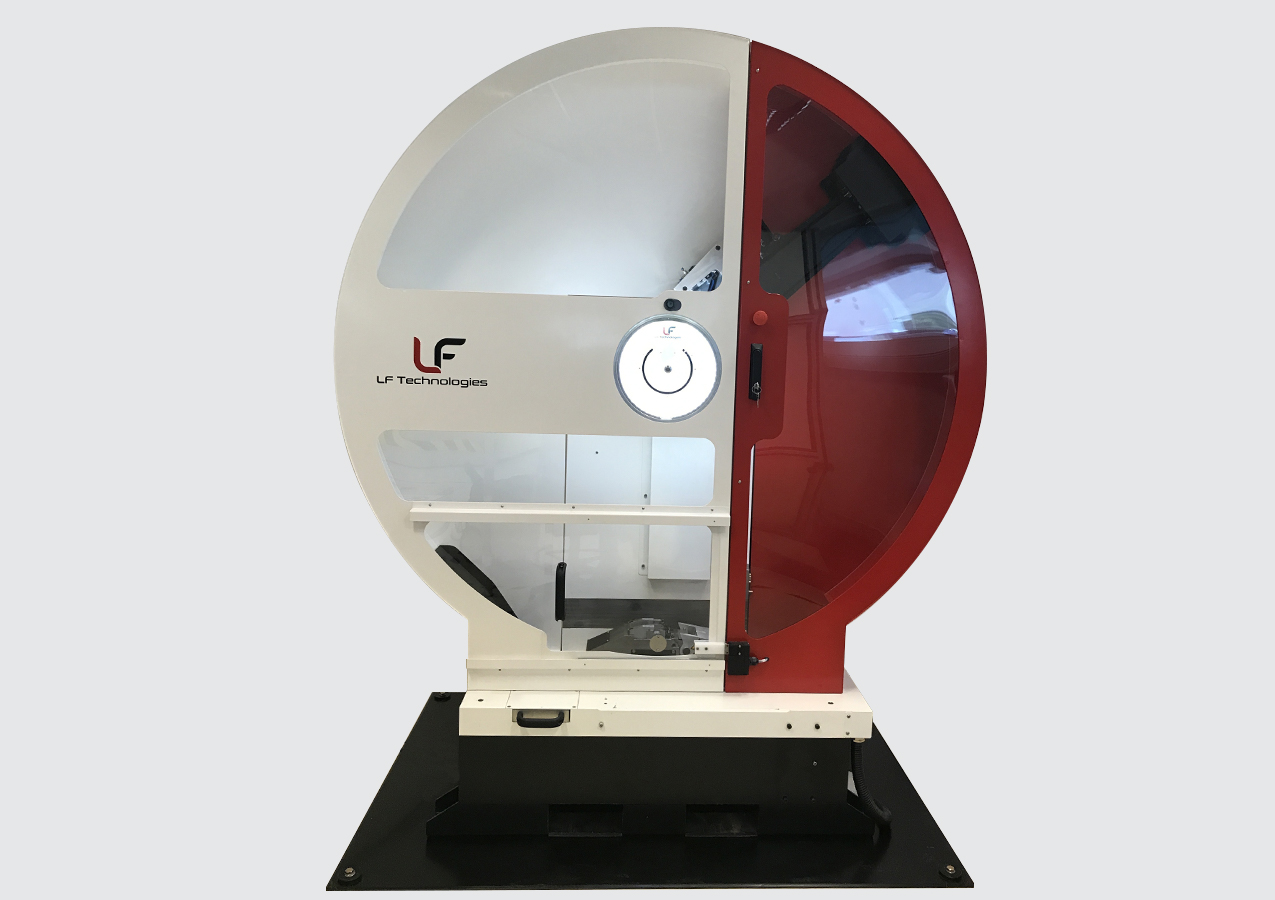

Racket frame shock bench

Shock resistance bench for racket frame. Vertical impact drop tester to test the frame distorsion after an impact. The tennis ball shaped impactor makes measures more realistic.

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Understanding LF Technologies shock test machines

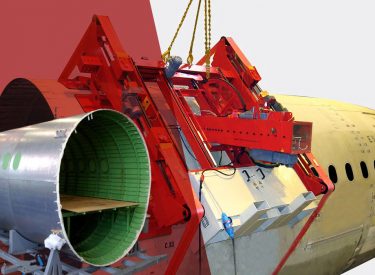

In the industrial world, shock test machines play a crucial role, especially in the sectors of transportation, automotive, aerospace, materials, and electronics. At LF Technologies, we offer solutions tailored to these specific needs. These devices allow testing various products to assess their resistance to mechanical shocks and impacts, as well as their behavior under these extreme constraints.

What is an Inertial Shock Test ?

An inertial shock corresponds to a collision between 2 pieces, particularly defined by the masses of each piece and their differential speed, which gives the shock energy (in Joules).

In this type of shock, the force reached is merely a consequence of the impact energy applied to the mechanical characteristics of the piece itself.

Technology

Several technologies are possible to perform this type of test:

- Drop weight impact tester (or drop tower) with piece dropping: in this case, the machine positions the test piece at a given height and releases it quickly to let it fall by its own weight onto a receiving tool. In this case, the speed is directly given by the drop height, and the energy depends on the height and mass of the tested object.

- Drop weight impact tester (or drop tower) with hammer dropping: in this case, the piece is fixed on a base (at the bottom), and it is struck by a falling mass equipped with a percussion hammer. The speed is given by the drop height, and the energy depends on the speed and mass of the hammer.

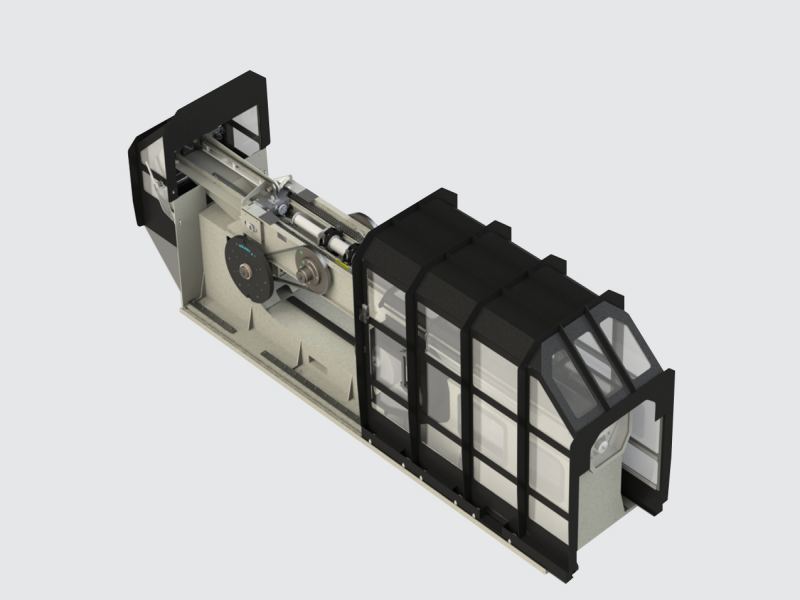

- Horizontal impact testing machine: the piece is fixed or placed on a fixed tool, and the hammer strikes it horizontally. In this case, the hammer is propelled by a motorized system that gives it its speed. The energy depends on the speed and mass of the hammer.

- Pendulum impact testing machiine or pendulum hammer : the shock is performed horizontally by a hammer, equipped with a mass, connected to a pendular arm. The arm is raised by a motor and released automatically (gravity fall).

The drop system (drop tower or pendulum) is generally simpler in design than horizontal shock test stand.

Horizontal shock test rigs offer more flexibility and ergonomics. Motorization allows better speed control, with quick acceleration ramps (less cumbersome machine) and automatic hammer catch in case of rebound. The construction of these machines also provides better ergonomics for the user.

Impact measurement

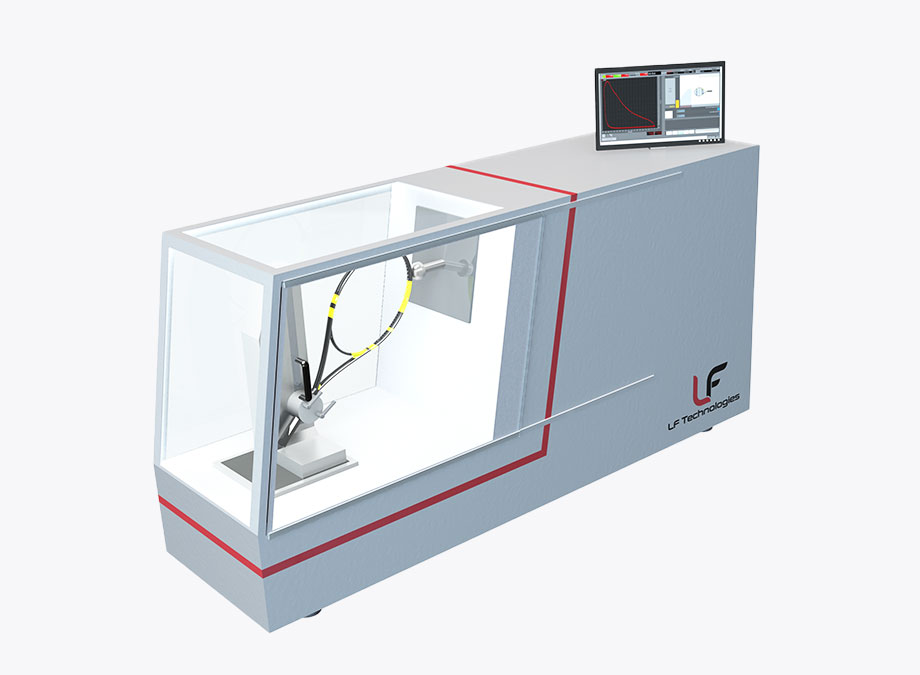

Regardless of the technology used, it is possible to measure speed, energy, and impact force (force/displacement curve).

Force measurement is ensured by a high dynamic sensor, capable of generating a precise force curve, even for very rapid shocks (< 1ms).

Position and speed measurement is ensured by a high-resolution digital rule (a few microns).

Several energy measurements are possible: measurement of potential impact energy, shock energy (force * displacement), elastic energy returned, etc.

User Interface: Simplicity and Intuitiveness

Our user interfaces are developed to ensure ergonomics and ease of use. They can be adapted to your specific needs, based on your specifications.

The impact tester interface allows easy setting of test data. The results, whether it’s the energies absorbed during impacts or the condition of products after shocks, are saved and systematically analyzed.

Test report

All our interfaces allow the automatic generation of test reports. These reports are customized based on your needs and include the test characteristics, measurement results, shock curves, and even automatic analysis of the shock curve.

Ensuring optimal product life span

This testing process simulates the “life profile” of a product, aiming to guarantee its longevity and reliability. By opting for LF Technologies’ solutions, professionals ensure the quality and precision of their shock tests, while benefiting from a tool designed to improve the performance and durability of the tested products.

At LF Technologies, our commitment is to provide state-of-the-art impact testing machines, ensuring not only compliance with international standards but also a significant improvement in product research and development. Our expertise and diverse range cater to the needs of multiple industries, thus contributing to innovation and safety.

Expert advice

Explore our blog dedicated to the world of mechanical test benches.

Immerse yourself in engineering excellence and discover the latest advances, tips and trends in the field.

How to properly calibrate your pressure sensor?

The most frequently used test bench sensors