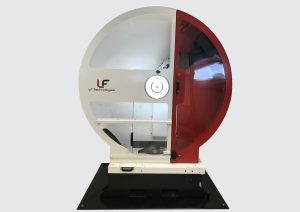

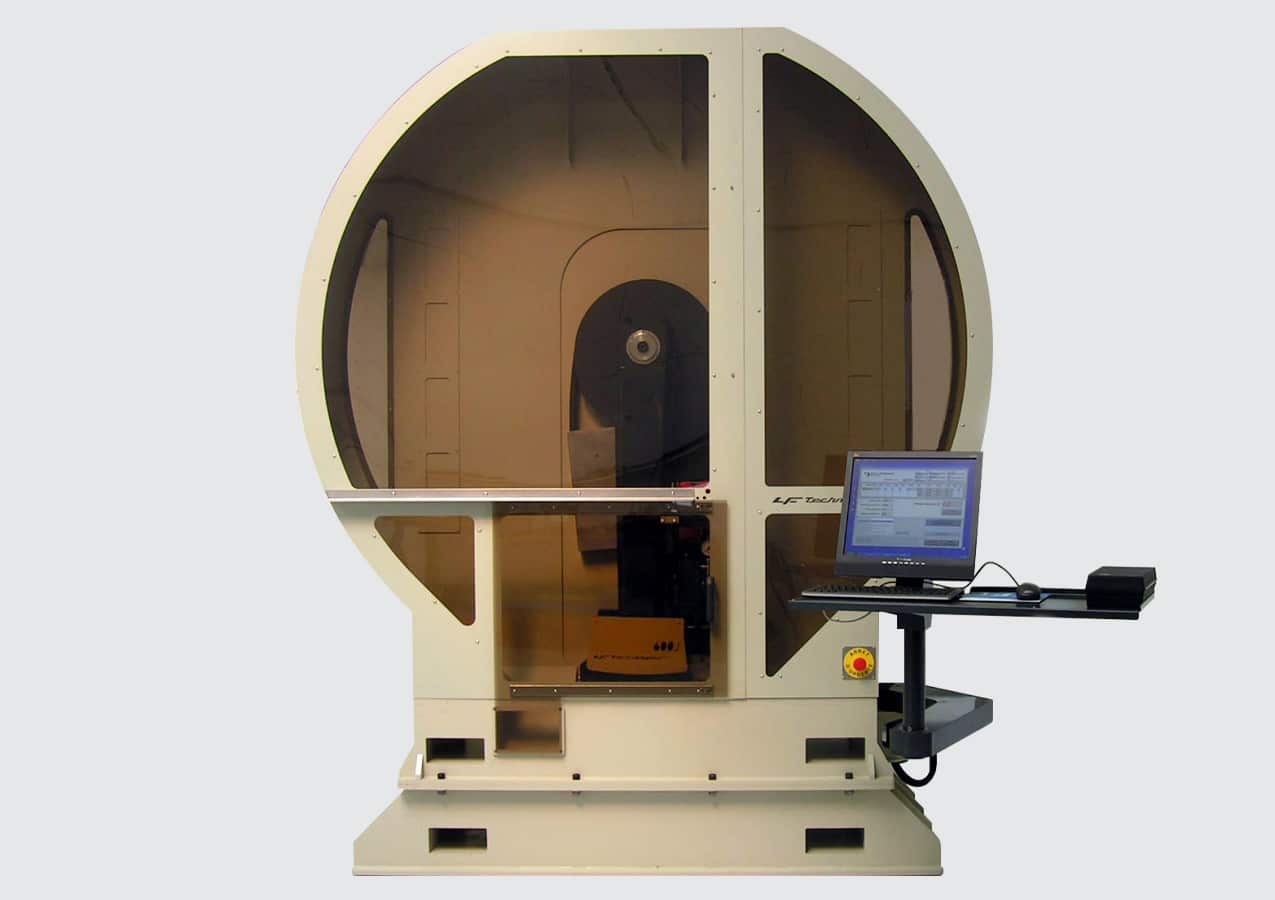

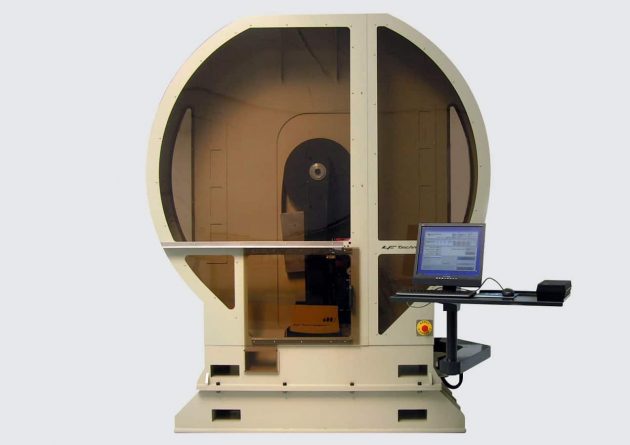

Impact pendulum

The pendulum-shear is a precise test rig that applies repeatable shocks (izod, charpy) to steel specimens until they break;

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

He is the first quality steel supplier for major activities.

Main functions

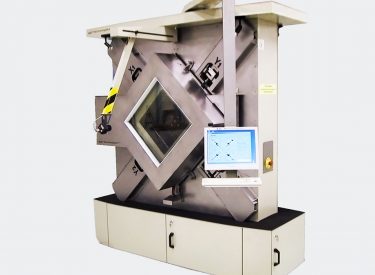

Objective

The objective is to be able to perform high-energy bending tests in accordance with NF EN 10045-1. These tests are carried out at high speed (production tests) in order to qualify all batches of sheet metal produced. The bench must guarantee total operator safety while remaining extremely ergonomic in use.

PROBLEMATIC ISSUES

- Ensures automatic positioning of the pendulum and on-the-fly catch-up after impact.

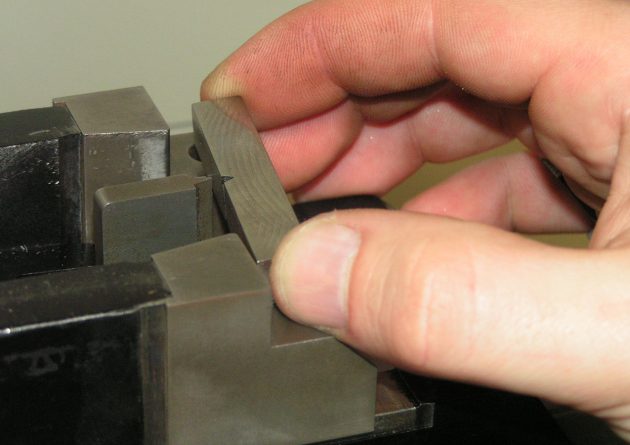

- The test is triggered very quickly once the operator has positioned the specimen, while ensuring that the specimen is positioned very precisely in relation to the hammer on impact.

- Automate test bench calibration

SOLUTION AND RESULT

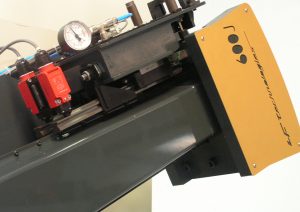

The bench is a pendulum impact tester complying with standard NF EN 10045, with a U-shaped hammer that can be fitted with different masses allowing tests from 300J to 800J. The machine is equipped with a motorised arm which ensures :

- positioning the pendulum at the desired height (as a function of speed or energy)

- le largage automatique du pendule

- re-hooking the pendulum on the fly after impact

Energy is measured by a very high-resolution encoder.

Test cycle :

The motorised arm positions the pendulum at the desired height, then the safety door is unlocked. The operator positions the test tube on the support and closes the door. As soon as the door is closed, the system automatically refocuses the test tube, releases the pendulum, measures the energy, rehooks the pendulum and repositions it for the next test. Thanks to this system, the specimen is broken less than 5 seconds after it is placed on the support by the operator, in complete safety. Operator safety is ensured by redundant systems (double locking of the pendulum on the arm, automated exit of a safety stop, double control loops for safety sensors, etc.) controlled by a safety PLC. The machine is designed to allow rapid changeover of the knife and specimen supports. The software developed specifically in Labview by our engineers enables :

- calculate and display the energy absorbed by the test piece, with automatic compensation for the natural damping of the pendulum

- display the measurements tested

- paramétrer des consignes de tests d’impact

- edit and print reports.

- automated calculation of geometric calibration, damping and oscillation period measurements

Tested product

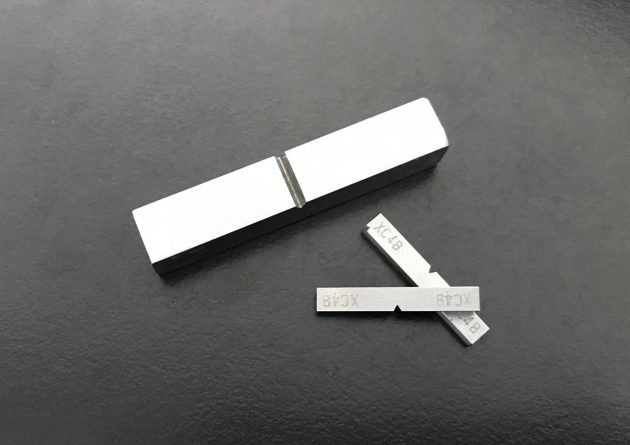

Impact pendulum test tube

The specimens tested on this impact rig are standardised for Charpy and Izod impacts for all materials.

Sample of Impact pendulum

The specimens tested on this impact rig are standardised for Charpy and Izod impacts for all materials.

Impact pendulum – impact test on test tube

OUR KEY TEST BENCH FOR THESE TESTS Impact pendulum – Impact Charpy, Izod MCMP

Main functions

Impact resistance is one of the most important properties to study when designing a part or appliance. The LF Technologies sheep-pendulum impact tester is used to determine the resilience of a specimen to an impact generated on it, in accordance with ASTM and ISO standards. Our impact and pendulum impact testing machines perform precise, repeatable impacts on a wide range of materials to determine the mechanical and physical characteristics of metals, polymers, composites and finished products, whether for R&D or quality control. Our machines perform Charpy and Izod tests, which meet international standards.

Operating mode

The automatic specimen centering system ensures simple, efficient use of the pendulum impactor. Specimens are impacted within 5 seconds of removal from the temperature unit. Operation is simplified by quick-change knife and specimen supports. The motorized pendulum hammer is equipped with a pneumatic hammer release system. Hammer reset is motorized for ease of use. A protective guard protects operators while the hammer is in motion.

Bench developed to meet these standards:

NF EN 10045-1

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.