Pressure and temperature control circuit

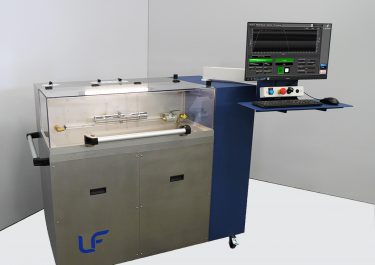

Special production machine designed to test the resistance of seals to pressure and temperature. This circuit can be connected to a pre-existing hydraulic bench.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

The proposed equipment is a fluid pressure and temperature control system for connection to the test chamber of an existing hydraulic bench.

Problematic Issues

Regulation of the temperature and pressure of the fluid flowing past the seal to be tested.

The fluid can be water or oil and must be able to be changed while minimising “dead” volumes, i.e. by limiting the quantity of residual fluid during a change.

Solution and result

The equipment designed by our technicians is a stand-alone system that is easy to transport.

Hydraulic circuit :

The system regulates pressure by means of a static pressure generator using a servo-controlled plunger piston.

Temperature control is provided by a heat exchanger between the main circuit and a secondary oil circuit.

The circulator and static pressure generator are designed to minimise “dead” volumes. The plungers are controlled by linear actuators.

The circulator and generator are connected to the test chamber by flexible hoses.

Static pressure generator :

The static pressure generator consists of a plunger piston. Pressure is regulated by the movement of the plunger piston.

Temperature control circuit :

The temperature control circuit heats or cools the secondary circuit. It is controlled by a PC equipped with software developed for this bench, which, among other things, enables measurements to be saved in spreadsheet format for use in Excel.

All safety functions are managed by a dedicated safety PLC.

The pressure and temperature control circuit is designed to connect automatically to the test chambers supplied by the customer.

Products testedA control PC, using software developed under LabVIEW, performs the control and measurement functions.

Joints dynamiques

Rotary seals

Pressure and temperature control circuit

The test loop designed and built by LF Technologies is used to regulate the pressure and temperature of a fluid, so that it can be connected to the test chamber of an existing hydraulic bench.

The system regulates pressure by means of a static pressure generator using a servo-controlled plunger piston.

The temperature is regulated by a heat exchanger between the main circuit and the secondary oil circuit.

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.