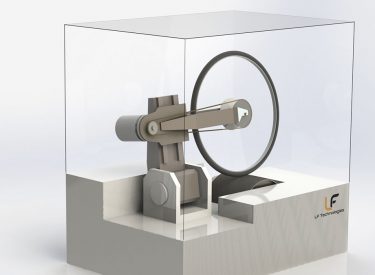

Racket frame shock bench

Shock resistance bench for racket frame. Vertical impact drop tester to test the frame distorsion after an impact. The tennis ball shaped impactor makes measures more realistic.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client is specialised in the making of sports rackets (tennis, badminton…), he designs frames and stringing (made of natural gut) for his products.

Main functions

Objective

The frame is designed to support the stress caused by the stringing. However, it is not tested to external shocks (when the ball hits the frame or the racket falls down for instance). Our client contacted us for a vertical impact drop tester to test this phenomenon.

PROBLEMATIC ISSUES

Our customer wants to carry out impact tests on different parts of the frame with varying energies. These parameters are difficult to modify on a vertical drop shaft. Safety is also an important consideration, as a vertical drop shaft involves a mass suspended at height which is released during the test.

SOLUTION AND RESULT

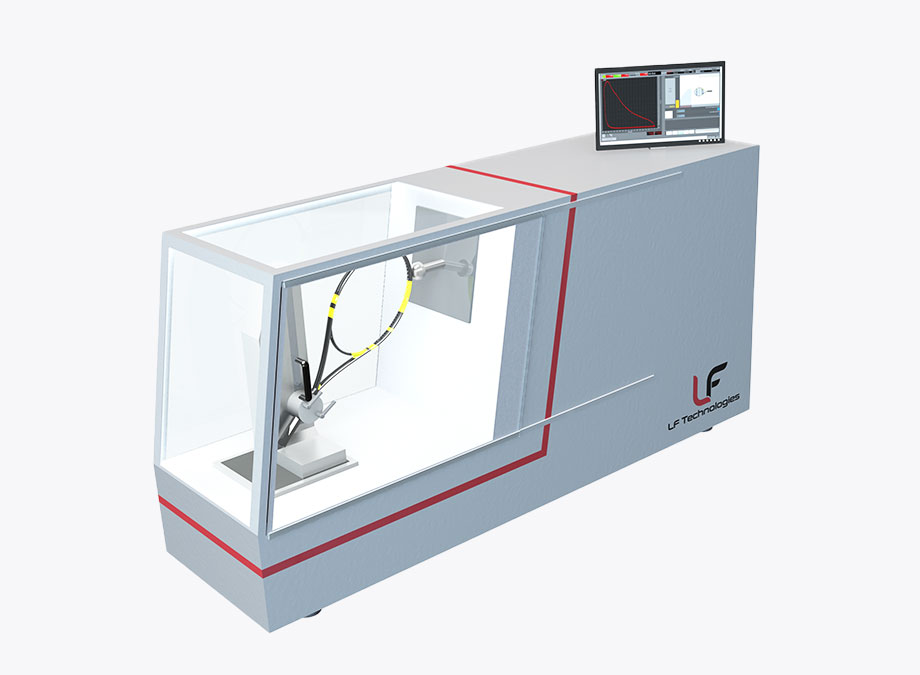

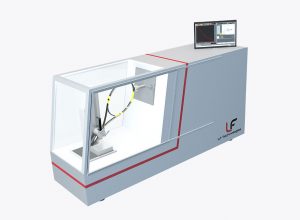

LF Technologies has designed an impact bench that perfectly controls the energy and position of the impact thanks to an adjustable support. This modular bench consists of a striker, propelled at high speed by a linear actuator, and has the advantage of taking up very little space.

The impact bench can perform repeated cycle tests to measure the wear and resistance of the racket frame over the long term and according to different uses. Detection of a break terminates the test or cycle.

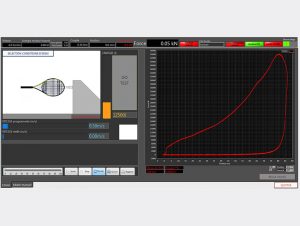

Force sensors on the racket frame support enable curves and measurements to be taken. They transmit the information to software specially developed for the test bench, which automatically saves the measurements and analyses them. It then edits and prints test reports.

It enables simple, intuitive cycles to be programmed and automatic tests to be carried out.

To protect the operator, the test area is fitted with a transparent protective cover. The bench has an “assembly” mode for safe adjustments.

The propulsion system is capable of recovering the impactor to avoid any rebound after the initial impact.

The bench can be enhanced with various options such as dynamic force measurement or motorised adjustment of the impact position. Last but not least, the impact test bench has a static test option.

Tested product

Tennis or badminton racket frame

The racket frame is the circular part that holds the strings; this part is also called the “racket head”.

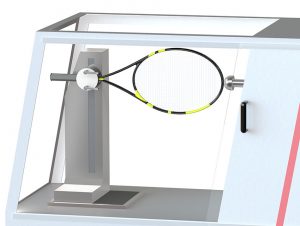

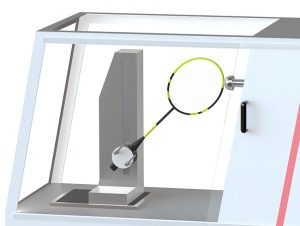

Tennis racket tested by the LF Technologies shock bench

Tennis racket tested by the LF Technologies shock bench

Badminton racket tested by the LF Technologies shock bench

Badminton racket tested by the LF Technologies shock bench

Tennis racket test

Tennis racket test

Badminton racket trial

Badminton racket trial

Tennis racket frame testing software screen

Tennis racket frame testing software screen

Racket frame shock bench

Racket frame shock bench

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Benoit Pelloquin

Mechanical Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.