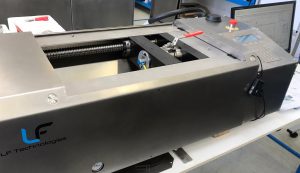

Valve leak test bench

Leak test bench for ball valves and valve extensions; Tests the airtightness and measures any leaks.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Main functions

Objective

Design and production of a leak-test bench for ball valves. This air-tightness check on valves is carried out at the end of the production line before the products are marketed.

PROBLEMATIC ISSUES

Solution and Result

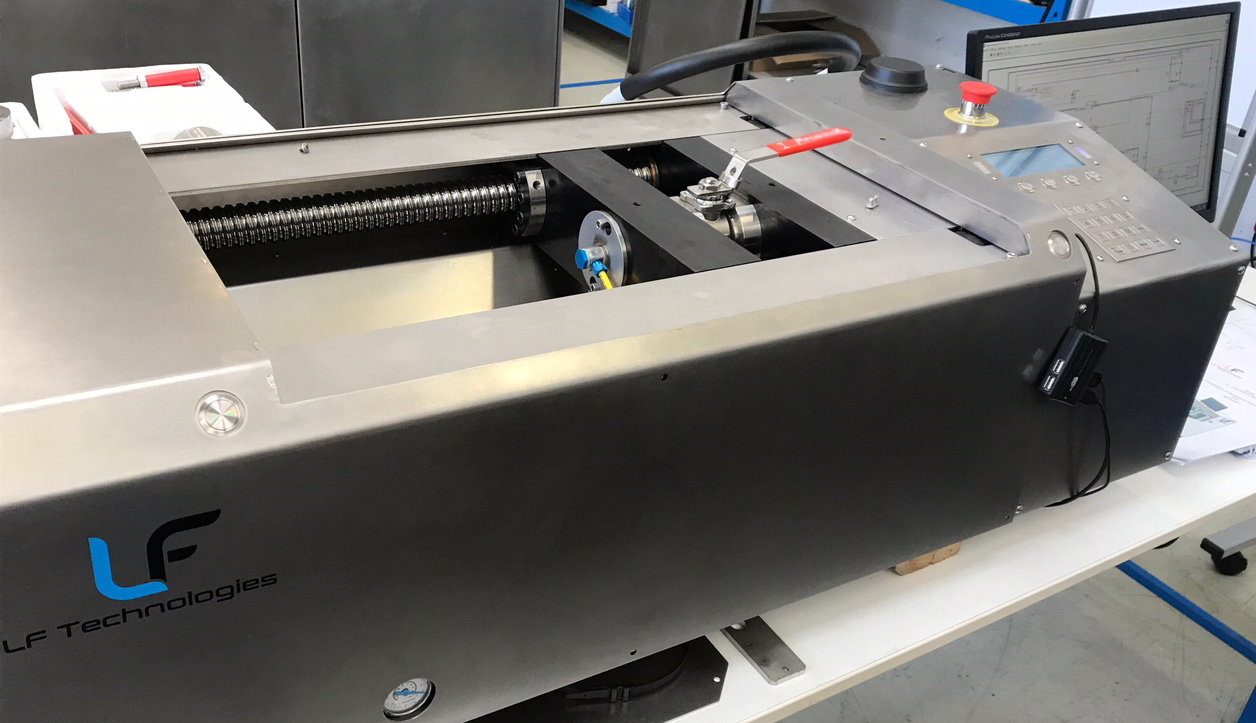

The proposed equipment is a system for gripping and tightening 1/4-turn valves, with a view to carrying out leak tests with an air injection system equipped with a micro-flow measurement.

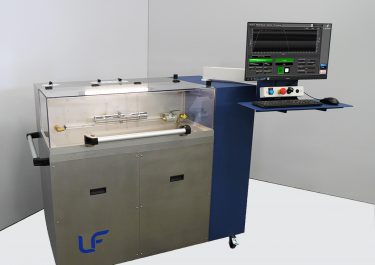

For each type of valve, the tooling consists of two identical parts that seal the valve on a flat surface and position the ball valve. The ergonomics of the bench have been optimised, and tooling movements are made using the two buttons on the front of the control console.

The control system (internal PC) has a set of predefined programs depending on the type of valves to be tested. It displays messages on the control panel indicating the various test stages to the operator (identify yourself, identify the product, identify the test programme used, position the valve, open the valve, close the valve, etc).

The Human Machine Interface enables :

To ensure the safety of operators during the leak test phase, an emergency stop button is located on the front of the bench. It activates the engine stop command.

Discover another case study for this customer

Before being put on the market, all valves undergo air-tightness tests (leakage measurement).

The verification system checks the closing and opening functions of the tool, with controlled tightening. The air injection and leakage measurement system is controlled via specific software using the control panel;

TESTED PRODUCT

Ball valves

A valve is a plumbing device that is operated to regulate a flow. There are several types of valves. The ball valve is either a shut-off valve to stop the flow of water or a flow control valve.

Valve Control Speed

A valve is a plumbing device that is operated to regulate a flow. There are several types of valves. The ball valve is either a shut-off valve to stop the flow of water or a flow control valve.

Valve air-tightness test bench

LF Technologies has designed and built a leak-testing facility for high-performance ball valves.

Leak tests are carried out using an air injection system equipped with a micro-flow meter.

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.