Rotary/Linear Actuator Module

- Ease of integration

- Stand-alone system

- Position, speed and effort management;

- Can be controlled by an external setpoint (slave settings)

Products tested

Sector of activity

FUNCTIONALITY

Rotary actuator

Description

The rotary actuator is an actuator with torque measurement and absolute angular position measurement over 1 revolution and incremental measurements (for several revolutions)

The rotary actuator is used to perform rotary movements.

It can be controlled in position, speed and torque.

It is equipped with a splined hollow shaft that can accommodate a variety of tools.

It can also be coupled to a linear actuator to combine translational and rotational movements (e.g. to operate single-control mechanical mixing valves).

Material characteristics

- Max. torque

from 3.7 to 25 N.m - Max. speed

30 to 214 rpm - Position, speed or torque control

- Transmission system possible by splines or the plate equipped with 4 tapped holes

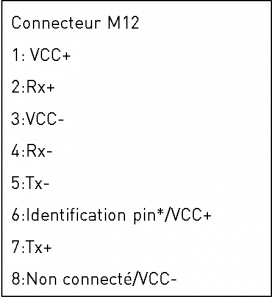

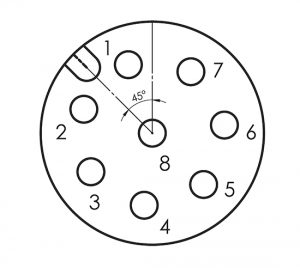

- M12 8-pin connection (power + communication)

- Possibility to use a through shaft

- Integrated control electronics

- Movement parameterisation via dedicated application or direct Ethernet communication for integration

Linear actuator

Description

The linear actuator is an electric cylinder equipped with a force measurement and an absolute position measurement

The linear actuator can be used for translational movements and can be controlled in terms of position, speed and force.

It is equipped with a splined hollow shaft that can accommodate a variety of tools. It can also be coupled to a rotary actuator to combine translational and rotational movements (e.g. to operate single-control mechanical mixing valves).

Material characteristics

- Max. force

from 179 to 325 N. - Max. speed

190 to 300 mm/s - Stroke 55 to 245 mm

- Position, speed or force control

- M12 8-pin connection (power + communication)

- Integrated control electronics

- Movement parameterisation via dedicated application or direct Ethernet communication for integration

Technology

- Stepper motor

- Integrated dimmer

- Absolute position measurement

- Integrated force and torque measurement

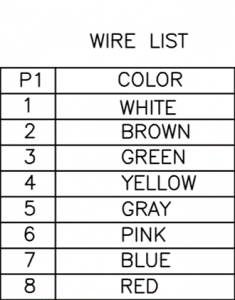

connecteurM12

connecteurM12-wire-list-rotatif

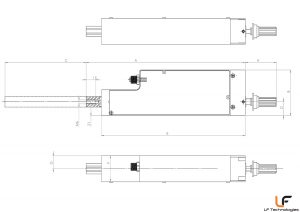

plan actionneur lineaire

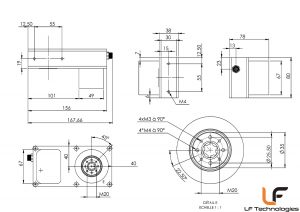

Plan actionneur Rotatif

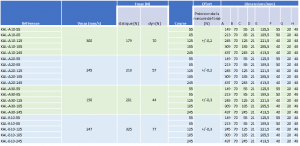

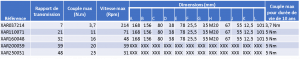

tableau-descriptif-technique

Tableau Descriptif Technique Actionneur Rotatif

Technical Description Rotary Actuator

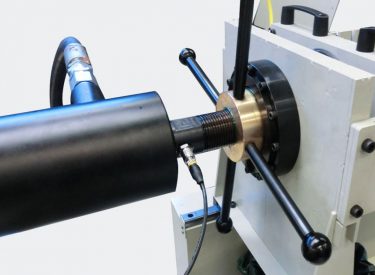

Montage actionneur rotatif

Mounting the rotary actuator

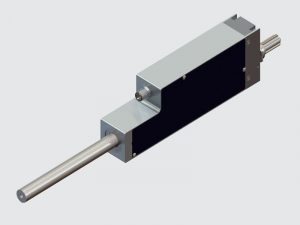

Actionneur linéaire

Linear actuator

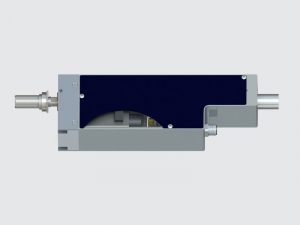

Actionneur linéaire vue interne

Internal view of the linear actuator;

Actionneur linéaire vue coupe

Sectional view of the linear actuator;

Actionneur linéaire

Linear actuator

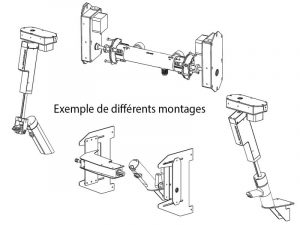

Exemple de montage pour robinetterie

Example of installation for taps

Montage actionneurs

Mounting actuators

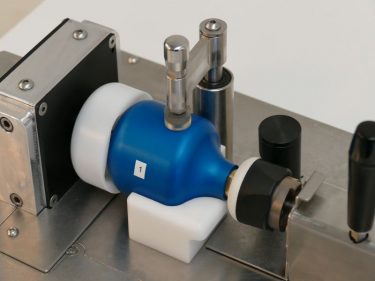

Essai écrasement balle

Ball crush test

Actionneur Rotatif

Rotary actuator

Plan-connecteur-actionneur-lineaire-new

Plan Connector Linear actuator

Applications integrating this module

Would you like to find out more about our special production machines ?

Find out more about the applications of our special machines for our customers.

ADD-ON MODULES

Explore our add-on modules to get the most out of your special machine !

Discover innovative solutions to further enrich your experience and optimize your results.