Pressure/flow test bench

The test bench made by LF Technologies performs tests on pressure reducing valves in accordance with the NF EN 1567 standard.NF EN 1567.

THE SOLUTION PROVIDED BY LF TECHNOLOGIES

Our client, a French company, is the European leader in the distribution and management of water in buildings.

Main functions

Objective

Testing pressure reducing valves according to different parameters before going into production.

PROBLEMATIC ISSUES

The test bench shall perform tests in accordance with EN 1567 (Building services valves – Water pressure reducing valves and combined water pressure reducing valves – Requirements and tests)

SOLUTION AND RESULT

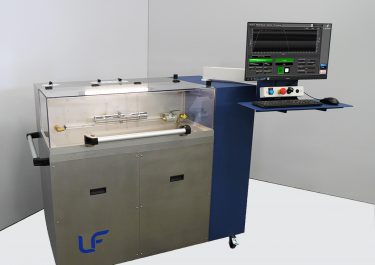

LF Technologies has designed a stand-alone test bench for pressure reducing valves equipped with a multi-stage centrifugal pump driven by a variable speed drive. A pressure sensor, placed at the inlet of the flow meter, allows the pressure to be controlled by varying the speed of the pump from 0.5 to 16 bar.

The pressure reducer to be tested is installed on the bench using suitable fittings.

Two sensors measure the ΔP between upstream and downstream of the test piece. The flow rate is varied from 0 to 11,000l/h by means of a motorised valve.

A circulator and a heat exchanger cool the water in the tank placed in the bench, and the temperature is monitored via a temperature sensor.

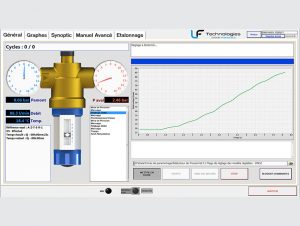

The program installed on the control PC was developed under LabVIEW. It allows to control the test pressure (via a pump) and the flow rate (via a proportional valve), but also to measure, display curves and record :

- the inlet and outlet pressures

- flow rate;

- temperature.

Tested product

Pressure reducing valves

A pressure reducer is a device that lowers the inlet pressure to obtain a set and constant value at the outlet.

OUR KEY TEST BENCH FOR THESE TESTS Taps – flow/pressure tests

FLOW

Main functions

The flow/pressure test bench is used to check the behaviour of sanitary fittings components under high pressure and high flow rates.

Operating mode

The station is equipped with a multi-stage centrifugal pump, controlled by a variable speed drive. This pump draws water from a tank inside the station and delivers it to the appliance under test through a magnetic flow meter. At the inlet of the product under test, a pressure sensor, precise and fast, allows the pressure control. Two level detectors placed inside the tank ensure that the pump always has water at the inlet.

Bench developed to meet these standards:

Do you have a project in mind ?

I'm here to advise you and propose solutions tailored to your needs.

Aurélien Cottin

Hydraulics Division

Other sector applications

Discover other test benches and special machines designed and built by LF Technologies.